Why Widely Implement Web Guide Systems for Cost-Effectiveness in Various Industries

In industries that process continuous materials such as paper, textiles, plastics, and metals, precision is critical to maintaining high product quality and operational efficiency. Web guide systems have become essential in ensuring that materials are properly aligned as they pass through various stages of production. While implementing web guiding control systems require an upfront investment, their long-term cost-effectiveness makes them invaluable across a range of industries.

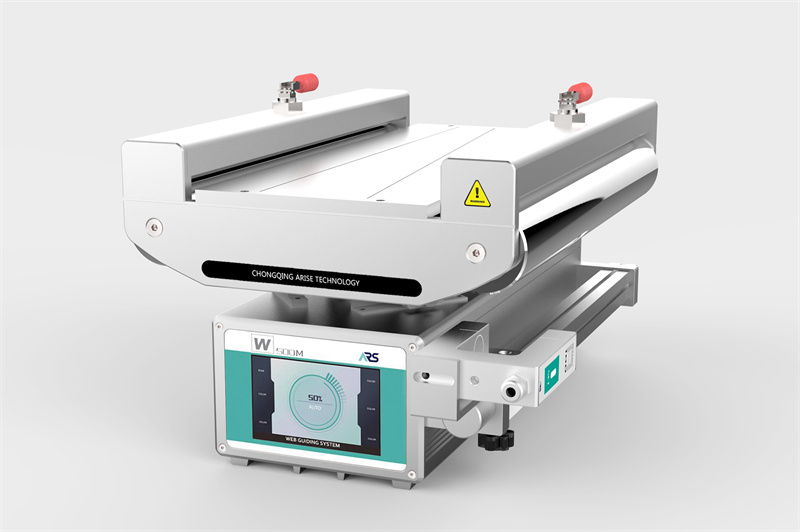

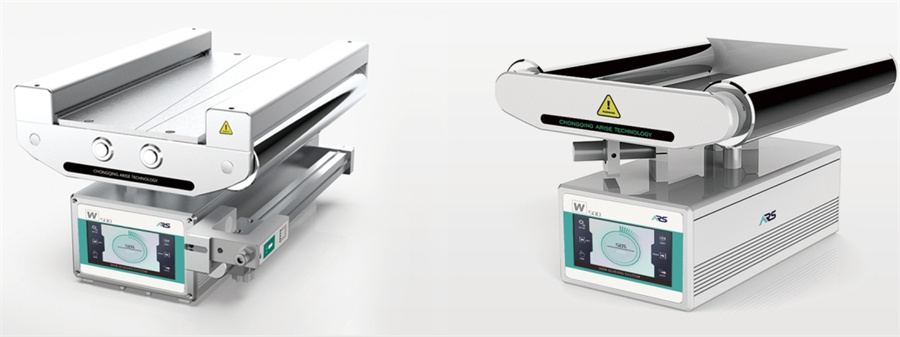

What are Web Guide Systems

This chart offers a concise overview of web guide systems, their components, functions, guiding types, etc.

| Aspect | Description |

| Definition | Web guide systems are automated mechanisms that maintain precise alignment of a moving web (material) through processing machinery. |

| Function | They ensure that materials such as paper, film, textiles, or metal follow a designated path, preventing misalignment and defects. |

| Core Components | 1. Sensors: Detects the edge or position of the web. 2. Actuators: Adjusts the web’s position. 3. Controller: Processes sensor data and sends commands to actuators. |

| Types of Web Guide Systems | 1. Edge Guiding: Aligns based on the material’s edge. 2. Center Guiding: Centers the web material. 3. Line Guiding: Tracks printed or marked lines. |

| Industries | Commonly used in industries like packaging, printing, textiles, metal processing, and more. |

| Purpose | To enhance production efficiency, reduce material waste, improve product quality, and prevent machine downtime. |

| Technological Integration | It can incorporate advanced technologies like machine learning, AI, and real-time feedback for enhanced performance. |

Key Benefits of Web Guide Systems for Cost-Effectiveness

This chart highlights how web guide systems contribute to cost-effectiveness through multiple operational improvements.

| Key Benefit | Description | Cost-Effectiveness |

| Reduced Material Waste | Ensures precise web alignment, minimizing errors like misalignment or defects. | Lowers costs associated with scrap, reducing material consumption. |

| Increased Production Efficiency | Enables faster machine speeds with accurate control, reducing downtime and errors. | Boosts production throughput, leading to higher output with fewer stoppages. |

| Lower Maintenance Costs | Prevents equipment wear through precision alignment and reduced vibrations. | Extends machinery lifespan, lowering repair and maintenance expenses. |

| Enhanced Product Quality | Maintains consistent web positioning, minimizing product defects and rework. | Reduces the need for quality checks and rework, saving on labor and production costs. |

| Energy Efficiency | Allows optimized operations at higher speeds with fewer corrections. | Lowers energy consumption, reducing operational energy costs over time. |

| Reduced Labor Costs | Automates manual web alignment processes, reducing the need for human intervention. | Cuts labor expenses by decreasing the need for manual adjustments and oversight. |

| Lower Rework Rates | Minimizes defects that would require reprocessing or discarding materials. | Saves costs associated with reworking or replacing defective products, leading to lower overall expenses. |

| Improved Machine Uptime | Less downtime due to fewer material jams and misalignment issues. | Increases overall productivity and revenue potential by maximizing machine uptime. |

Cost-effectiveness of Web Guide Systems in Various Industries

1. Printing Industry

In the printing industry, precision is paramount. Web guide systems ensure accurate material alignment, reducing print defects like registration errors and misprints. This leads to lower material waste and decreased downtime due to fewer machine stoppages. The result is improved overall production efficiency and a direct reduction in operational costs.

2. Packaging Industry

Packaging operations require high-speed material processing and exact alignment to maintain quality standards. Web guide control systems minimize errors such as misaligned cuts and folds in packaging process, reducing waste in packaging materials. They also optimize production speeds while maintaining accuracy, which helps lower energy consumption and increases throughput, making the entire process more cost-efficient.

3. Textile Industry

The textile industry benefits from the accurate positioning of fabrics during cutting, sewing, and finishing processes. Web guiding systems reduce fabric wastage due to misalignment and increase the speed of production lines. These systems also minimize the need for manual intervention, leading to lower labor costs and enhanced production consistency.

4. Paper Manufacturing Industry

Paper production is a high-volume process where even minor deviations in web alignment can result in significant material loss. Web guiding systems ensure precise tracking of paper webs, minimizing errors and reducing paper waste. Additionally, by enabling faster operation speeds and reducing equipment wear, web guide systems lower energy costs and maintenance expenses.

5. Metals and Foils Industry

In industries dealing with metal sheets and foils, accurate alignment is essential to avoid costly material defects and ensure quality. Web guiding system equipment offer precise control, minimizing errors in cutting, slitting, or rolling processes. This reduces the need for rework, saves on material costs, and extends the lifespan of expensive machinery by reducing wear and tear.

6. Flexible Films Industry

Web guide systems are crucial in the production of flexible films used for packaging, electronics, and insulation. Precise control helps avoid defects in thin, delicate films, significantly reducing scrap rates. The systems allow for high-speed operations while ensuring uniform quality, cutting operational costs through reduced downtime and material waste.

To sum up, the cost-effectiveness of implementing web guide systems in various industries is evident in the significant reductions in material waste, operational inefficiencies and product defects. By ensuring precise alignment and efficient material handling, web guiding system equipment allow businesses to maximize productivity, enhancing product quality and minimize downtime. Though the initial investment may seem substantial, the long-term benefits in terms of cost savings, improved efficiency and product quality, make web guide control system become an effective solution for any industry dealing with continuous material processing.