Why Choose the Integration of Web Inspection Systems with Print Inspection

In the fast-paced world of production, where precision and quality are essential, the integration of print inspection capabilities into web inspection systems stands out as a transformative advancement. This convergence of technologies has revolutionized quality assurance practices, empowering industries ranging from packaging to printing with unprecedented accuracy and efficiency.

Understanding Web Inspection Systems

Web inspection systems have long been the cornerstone of quality control in industries that rely on continuous materials, such as paper, film, or textiles.

| Aspect | Description |

| Definition | Web inspection systems are automated systems used to inspect and monitor the quality of webs or materials as they move along a production line. |

| Purpose | The primary purpose of web inspection systems is to detect defects, flaws, or irregularities in the material, ensuring product quality and minimizing waste. |

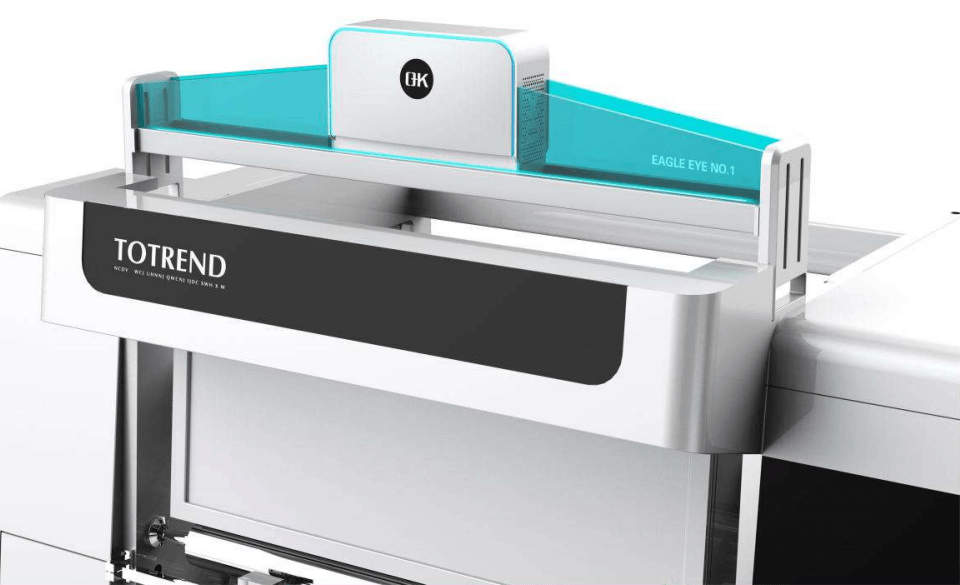

| Components | Web inspection systems typically consist of components such as cameras, lighting systems, sensors, image processing software, and control units. |

| Inspection Techniques | Common inspection techniques include vision-based inspection, optical inspection, surface inspection, and defect detection algorithms. |

| Inspection Parameters | Web inspection systems analyze various parameters such as color, texture, size, shape, surface defects, printing errors, and material thickness. |

| Integration | Web inspection systems can be integrated into production lines for real-time inspection or operated as standalone units for offline inspection. |

The Evolution: Integration of Web Inspection Systems with Print Inspection

To meet the growing demand for perfect printed goods, manufacturers have increased the capabilities of web inspection systems by incorporating print inspection functionality. This collaboration enables manufacturers to assess not only the physical integrity of the material, but also the accuracy and quality of printed content.

Key Features of Web Inspection Systems Integrated with Print Inspection

1. Comprehensive Inspection

Integrated systems offer complete inspection capabilities, allowing for simultaneous examination of the material surface and printed content. This ensures that printing problems, such as misprints, color discrepancies, and registration issues, are recognized in addition to physical defects in the material.

2. Real-time Detection

Advanced imaging technology and intelligence algorithms enable real-time detection of printing flaws as the material passes through the web inspection system. This proactive approach allows manufacturers to identify and address defects immediately, minimizing the production of defective or non-compliant products.

3. Multi-parameter Inspection

Integrated systems can inspect multiple parameters of printed content, including text, graphics, barcodes, and color fidelity. This enables thorough quality assessment and ensures adherence to design specifications and regulatory standards.

4. Adaptability

Integrated web inspection systems are highly adaptable to diverse printing processes and materials, accommodating variations in substrates, inks, and printing methods. They can be configured to meet the specific requirements of different industries and applications, providing flexibility and versatility in quality assurance.

5. Data Analytics

Integrated systems generate valuable data insights, capturing information on defect rates, production trends, and performance metrics. This data can be analyzed to identify root causes of defects, optimize production processes, and drive continuous improvement initiatives.

Benefits of Web Inspection Systems Integrated with Print Inspection

1. Improved Quality Control

By combining web and print inspection capabilities, producers can ensure the highest levels of quality and accuracy in printed goods. Defects in both material integrity and printing are recognized and corrected, resulting in goods that satisfy the highest quality standards and client expectations.

2. Reduced Waste and Rework

Real-time defect detection minimizes the production of defective or non-compliant products, reducing waste and the need for costly rework. Integrated systems enable early intervention and corrective action, preventing defective products from progressing further in the production process.

3. Enhanced Efficiency

Integrated inspection systems streamline quality assurance processes, reducing inspection times and minimizing manual intervention. This leads to improved production efficiency, faster cycle times, and increased throughput, ultimately driving cost savings and operational excellence.

4. Compliance Assurance

Integrated systems help assure regulatory compliance and industry standards by validating the quality and legibility of printed text. This is especially important in regulated areas like pharmaceuticals, food packaging, and labeling, where precise compliance is required.

5. Increased Customer Satisfaction

By delivering products with consistent quality and accuracy, manufacturers enhance customer satisfaction and build trust in their brand. Integrated inspection systems help maintain brand integrity, reduce the risk of recalls or product returns, and enhance overall customer experience.

Industrial Applications of Web Inspection Systems Integrated with Print Inspection

The integration of print inspection capabilities into web inspection systems has found diverse applications across various industries, revolutionizing quality control and production processes.

1. Packaging Industry

In the packaging industry, where product labeling and packaging play a crucial role in brand recognition and consumer safety, integrated inspection systems ensure the accuracy and integrity of printed materials.

- Label Inspection: Verification of label content, including product information, barcodes, and expiration dates, to ensure compliance with regulatory requirements and brand standards.

- Printed Packaging: Inspection of printed packaging materials, such as cartons, boxes, and bags, to detect defects, misprints, or color variations that may affect product presentation or shelf appeal.

- Security Printing: Inspection of security features, such as holograms, watermarks, and microtext, to prevent counterfeiting and unauthorized tampering of packaging materials.

2. Printing and Publishing

In the printing and publishing industry, where print quality is paramount, integrated web inspection systems enable precise quality control and defect detection in high-volume printing applications.

- Newspapers and Magazines: Inspection of printed newspapers, magazines, and periodicals for printing defects, color accuracy, and registration errors, ensuring consistent print quality and reader satisfaction.

- Books and Catalogs: Verification of text and image quality in printed books, catalogs, and promotional materials to maintain brand consistency and enhance readability.

- Variable Data Printing: Inspection of variable data, such as serial numbers, barcodes, and personalized content, for accuracy and legibility in direct mail, transactional printing, and personalized marketing campaigns.

3. Labeling and Packaging Compliance

In regulated industries such as pharmaceuticals, food and beverage, and medical devices, integrated inspection systems for printing quality play a critical role in ensuring compliance with labeling and packaging standards.

- Pharmaceutical Packaging: Verification of medication labels, dosage instructions, and safety warnings to meet regulatory requirements and ensure patient safety.

- Food Packaging: Inspection of food labels, nutritional information, and allergen warnings to comply with food labeling regulations and provide accurate information to consumers.

- Medical Device Labeling: Verification of labeling and packaging materials for medical devices, including instructions for use, sterilization indicators, and regulatory markings, to ensure compliance with industry standards and regulatory guidelines.

4. Flexible Packaging and Converting

In industries such as flexible packaging and converting, where materials undergo complex printing and converting processes, integrated inspection systems ensure quality and consistency throughout production.

- Flexible Packaging Films: Inspection of printed films, pouches, and wrappers for defects, print registration, and color consistency, ensuring high-quality packaging for food, pharmaceuticals, and consumer goods.

- Label Converting: Verification of label materials, die-cutting accuracy, and print quality in label converting processes, ensuring that labels meet customer specifications and adhere to brand standards.

- Digital Printing: Inspection of digitally printed materials for defects, color accuracy, and variable data integrity, enabling high-speed production of personalized packaging, labels, and promotional materials.

Future Innovations in Integrated Web Inspection Systems for Printing Quality Assurance

As technology continues to advance, we can expect further innovations in print inspection capabilities integrated into web inspection systems. Enhanced imaging resolution, artificial intelligence algorithms, and machine learning approaches will allow for more precise flaw detection, increased accuracy, and higher adaptability to various printing processes. Manufacturers will increasingly rely on integrated inspection systems to meet the evolving demands of quality assurance in an ever-changing production landscape.

Conclusion

The integration of print inspection capabilities into web inspection systems represents a significant advancement in manufacturing quality assurance. By combining the strengths of both technologies, manufacturers can achieve comprehensive defect detection, ensure print accuracy, and optimize production efficiency.