Why Choose the Integrated Web Tension Controllers with Web Guiding Systems

Precision control of web tension and web guiding is critical in industrial industries that entail continuous material processing, such as printing, converting, packing, and textiles, to assure product quality and production efficiency. In this article, we will look at how web tension controllers can be integrated with automated web guiding systems, highlighting the benefits and uses of this innovative combination.

What are Web Tension Controllers and Web Guiding Systems

Understanding Web Tension Controllers

The evenness and consistency of a material (often a web or roll of material) as it passes through a manufacturing process is referred to as web tension. Maintaining adequate web tension is critical for defect prevention, precise control of printed materials, and web breakage prevention. Throughout the manufacturing process, web tension controllers are used to achieve and maintain the desired degree of tension. These controllers work by adjusting the speed or torque of components like motors, brakes, or clutches to keep the web material at the desired tension level.

The Role of Web Guiding Systems

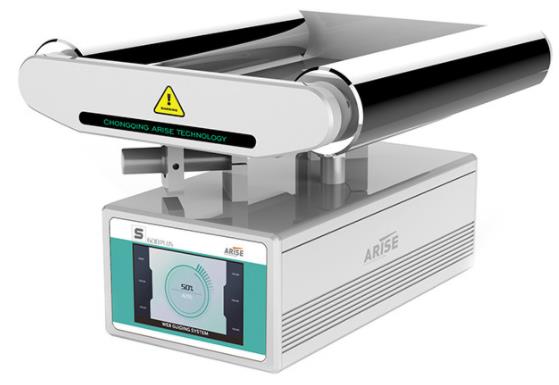

Web guiding systems are specialized machines that keep continuous webs of materials aligned and in the appropriate position as they pass through various machines and processes. Paper, film, fabric, metal, and other materials are examples of such materials. Web guiding systems ensure that web material remains centered, aligned, and defect-free as it moves through the production line.

Web guide control systems are essential in many industrial processes where accurate alignment and management of continuous materials or webs is crucial to product quality and process efficiency. These systems are used in a variety of industries, including printing, converting, packaging, textiles, and paper manufacturing.

Key Components of Web Guiding Systems

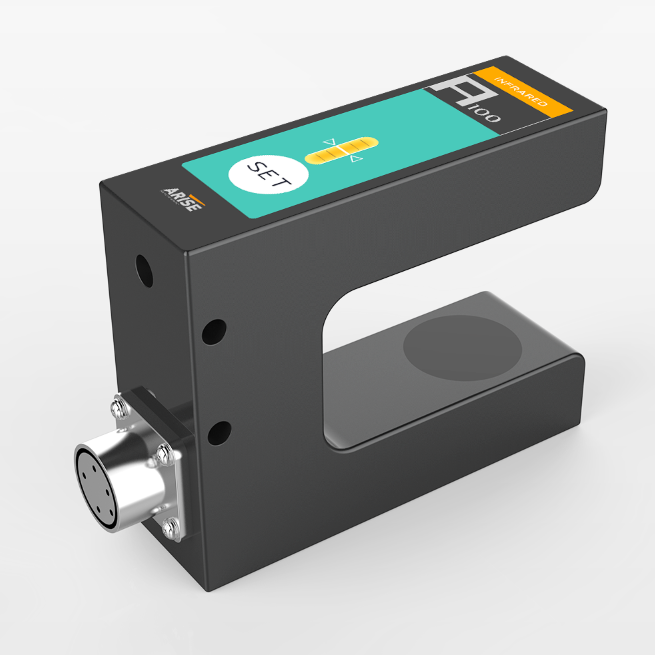

Web Sensors: Sensors detect the web material’s position or alignment.. Common web guide sensors include edge sensors, line sensors, or contrast sensors, depending on the type of material and process.

Controller: The web guiding controller analyzes the sensor inputs and determines the modifications required to maintain appropriate web alignment. It transmits control signals to the actuators.

Actuating Devices: Based on the controller’s directions, actuating devices such as steering guides, rollers, or moving frames physically modify the position of the web material.

User Interface: Some web guiding machine provide user interfaces that enable operators to configure parameters, monitor system performance, and make manual adjustments as needed.

What are the Advantages of the Integrated Web Tension Controllers with Web Guiding Systems

Manufacturers frequently connect web tension controllers with automated web guiding systems to optimize material processing and product quality. This combination provides various benefits:

Precise Control

Web tension controllers regulate tension in real-time to keep it consistent and within the specified range. When integrated with web guiding systems, this precise control extends to the alignment and tracking of the material, resulting in high-quality finished products.

Reduced Waste

Proper tension control and web guiding minimize material waste. By preventing misalignment or over-tensioning, manufacturers can reduce the occurrence of defects and web breakages, ultimately saving valuable resources.

Enhanced Efficiency

Automated systems are more efficient and require fewer manual modifications. This leads to increased productivity since operators can concentrate on other key components of the manufacturing process.

Improved Product Quality

Consistent tension and alignment help to improve the overall quality of the finished product. The integration of these systems ensures that each stage of the process is done precisely, whether it is printing, laminating, coating, or slitting.

Versatility

Web tension controllers and web guiding systems are adaptable and can be integrated into various machines and processes. This versatility makes them suitable for a wide range of industries and applications.

What are the Common Applications of the Integrated Web Tension Controllers with Web Guiding Systems

Printing

In the printing industry, precise tension control are crucial for producing high-quality, accurately printed materials. Integrated systems ensure that the paper or substrate advances smoothly through the printing press.

Packaging

The combination of tension control and web guide in packaging machines ensures that package materials are cut, folded, and sealed properly, eliminating waste and optimizing packing quality.

Textiles

Textile manufacturers rely on these integrated systems to ensure the consistent tension and alignment of fabrics, preventing defects and improving the quality of finished textile products.

Converting

In the converting industry, where materials are transformed into various products, integrated systems are essential for ensuring that each step of the process is carried out accurately and efficiently.

Labeling

Precision web tension and web guiding system are critical in label printing and application to achieve correctly positioned and fastened labels on items.

Conclusion

The integration of web tension controllers with web guiding systems represents a significant advancement in manufacturing technology. In a variety of industries, these integrated systems play a critical role in increasing efficiency, decreasing waste, and improving product quality. As technology advances, we can anticipate more advancements in the fields of web tension and web guiding control, propelling the manufacturing industry toward higher automation and precision.