Why Choose a Printing Quality Inspection System

Maintaining high-quality standards is critical in the dynamic world of printing, where accuracy and precision are critical. A printing quality inspection system is a breakthrough that has transformed the way printing companies ensure high-quality print output. In this post, we will look at the importance of a printing quality inspection system, its components, and the advantages it provides to the printing process.

What is a Printing Quality Inspection System

A printing quality inspection system is a sophisticated software-based solution that is integrated into the printing process to automatically examine and verify the quality of printed documents. This system examines print samples in real-time, comparing them to predetermined quality metrics, using sophisticated technologies such as computer vision, image processing, and artificial intelligence.

What are the Key Components of a Printing Quality Inspection System

A printing quality inspection system is a sophisticated technological solution designed to analyze and verify the quality of printed materials automatically.

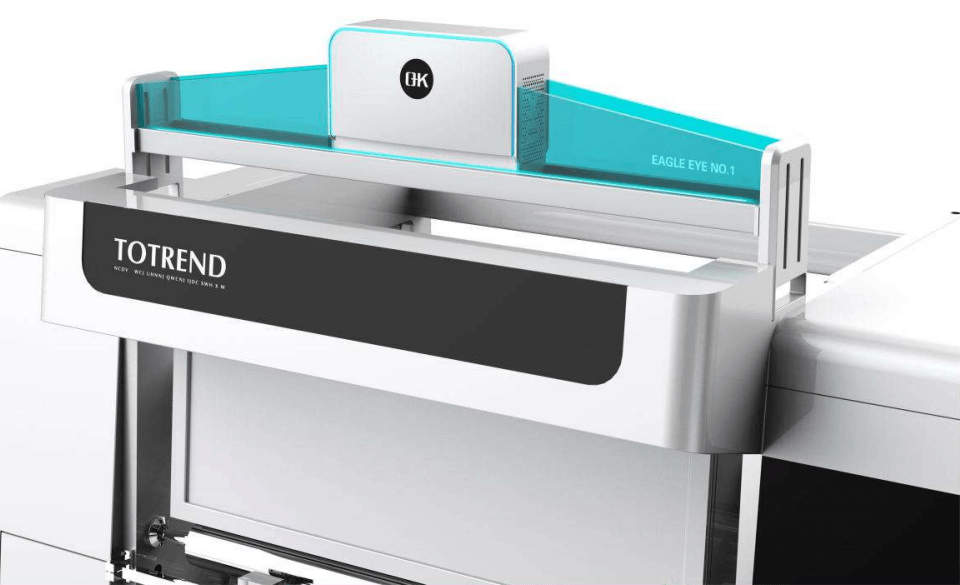

Camera or Image Sensor

The camera or image sensor is an essential component of the system. It collects high-resolution photographs of printed materials, allowing the system to examine and assess print quality. Multiple cameras can be carefully placed to cover various sections of the print, ensuring thorough inspection.

Image Processing Software

The system’s fundamental component is image processing software. It analyzes images acquired by the camera or image sensor, extracting important features and properties of the printed materials. Advanced algorithms examine the photos for faults, color variations, alignment issues, and other quality-related issues.

Artificial Intelligence (AI) and Machine Learning (ML)

In a modern printing quality inspection system, AI and ML algorithms play an important role. These technologies allow the system to learn from previous print samples, adapt to changing print kinds, and increase its accuracy over time. The AI-powered system improves its ability to detect and identify faults, resulting in better quality control.

Quality Metrics and Thresholds

The system is configured with quality measurements and thresholds that act as benchmarks for acceptable print quality. These measurements may include color accuracy, alignment, print resolution, and other printing-specific factors. When the actual print quality deviates from these predefined standards, the system sends notifications to the user to take corrective action.

Light Source and Illumination System

For optimal image capturing, an adequate light source and illumination system are required. To guarantee reliable analysis of printed materials, lighting conditions must be consistent and controlled. Depending on the printing method and materials, several lighting strategies, such as back lighting or diffuse lighting, may be used.

User Interface

A user-friendly interface makes it simple for operators to engage with the system. The interface monitors the inspection process in real time, displays the inspection results, and allows operators to evaluate quality reports. Options for altering system settings, calibration, and establishing quality parameters may also be included.

Data Storage and Analytics

A data storage capability is commonly included in a printing quality inspection equipment to save inspection results and historical data. This information can be used for performance analysis, trend detection, and process optimization. Analytical tools may be integrated to extract valuable insights for continuous improvement.

Integration with Printing Equipment

The quality inspection system can be linked directly to the printing equipment or control system for smooth integration into the printing workflow. This interface enables automatic printing inspection, reducing downtime and streamlining quality control procedures.

Benefits of a Printing Quality Inspection System

Improving Printing Quality

The fundamental advantage of a quality inspection system is an increase in print quality. Even minor flaws, such as misprints, color variances, streaks, and smudges, can be detected and identified by the system. The system enables fast corrective action by detecting these flaws early in the printing process, resulting in faultless print output.

Increasing Productivity

The use of a dedicated system to automate the quality inspection process lowers the requirement for manual examination. This saves time and money, allowing printing companies to be more productive. The system can analyze prints at a much higher speed than human inspectors, thereby expediting the production process.

Waste Reduction

A web inspection system for printing quality reduces waste by identifying and rejecting bad prints early on. It aids in the avoidance of poor or unusable prints, which can be costly in terms of materials and time. Waste reduction contributes to economic savings and a more environmentally friendly printing operation.

Consistent Output

Printing companies may maintain consistent print quality across all print runs by using the precision of a quality inspection system. The system adheres to preset quality requirements and measurements, eliminating print output variations. This consistency improves both the brand’s reputation and consumer satisfaction.

Real-time Monitoring and Reporting

Through a user-friendly interface, operators may watch the inspection process in real-time. They can evaluate quality reports, monitor the printing process’s performance, and make fast adjustments if necessary. This proactive approach ensures quality control during production.

Enhancing Customer Satisfaction

Printing enterprises can exceed client expectations by consistently producing high-quality prints. Customers who are satisfied are more likely to return for future projects and suggest the printing company to others, creating positive word-of-mouth and business growth.

Continuous Improvement

Through analytics, a printing quality inspection machine offers useful data and insights. Operators can monitor performance patterns, identify areas for improvement, and optimize printing processes over time. Continuous improvement initiatives result in increased efficiency and quality gains.

Summary

Maintaining flawless print quality is critical for success in the highly competitive printing industry. A printing quality inspection system powered by innovative technology provides a comprehensive solution for achieving and maintaining the highest printing output standards.