What is a Web Video Inspection System for Printing and Label Quality

Consistent quality is critical in the fast-paced and competitive world of printing and label manufacturing. Precision and perfection are required to meet customer expectations and regulatory criteria while producing consumer product labels, packaging materials, or print media. To assure top-notch quality and minimize errors, a web inspection system for printing and label quality is implemented. It is a cutting-edge quality control system tailored to the printing industry. The web video inspection system is a sophisticated combination of hardware and software technologies that monitor, analyze, and examine printed materials in real-time during production. The technology can detect and identify numerous faults and imperfections in printed output, ensuring that only ideal products reach the market.

Key Features and Functions of a Web Inspection System for Printing and Label Quality

The printing quality inspection system is a powerful instrument that is revolutionizing the printing business by increasing precision, minimizing waste, and ensuring high quality in every print created.

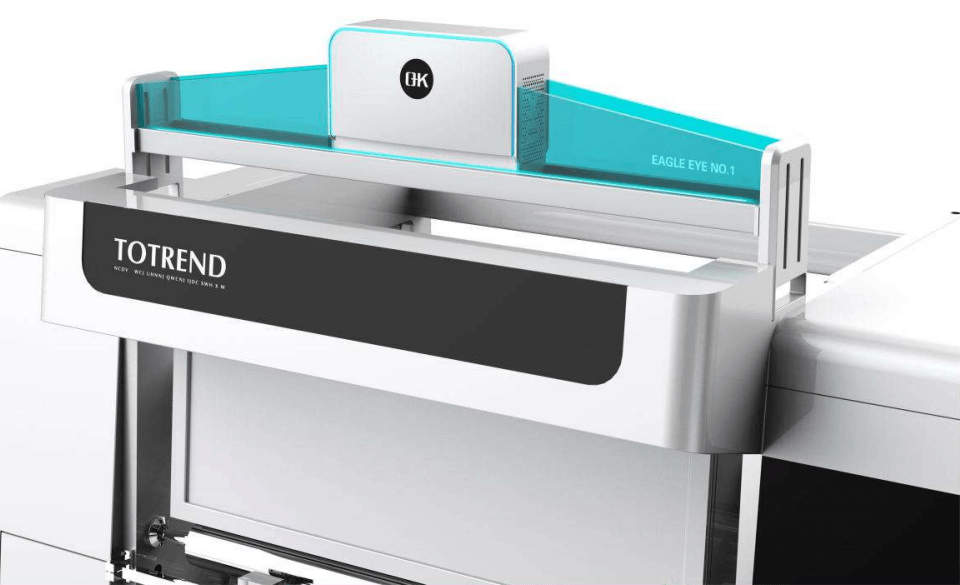

High-resolution Imaging

The web inspection system makes use of high-resolution cameras and sensors that can capture detailed photographs of printed materials. These cameras can zoom in on small areas, enabling for precise assessment of minute faults and inconsistencies in printed output.

Defect Detection and Identification

The web inspection vision system’s intelligent defect detection and identification algorithms are at the heart of the system. It scans for flaws such as misprints, color variations, streaks, smudges, specks, and registration issues in real time on the collected photos. The system can automatically identify and categorize several types of faults for further investigation and action.

Color Consistency and Accuracy

sustaining color consistency is crucial in the printing industry for satisfying client expectations and sustaining brand identification. The web inspection machine guarantees that the printed colors meet the required criteria, resulting in consistent output. Color discrepancies and variations can be detected, allowing operators to make the appropriate modifications to preserve color fidelity.

Registration Control

Proper registration, or the alignment of different colors and printing plates, is critical to avoiding misregistration errors, which can result in fuzzy or overlapping prints. The web inspection vision system ensures that colors and pictures line exactly during the printing process by verifying registration accuracy.

Real-time Monitoring and Alerts

The system monitors the printing process in real time, checking each produced item continuously. In the event of detecting a defect or deviation from the defined quality standards, the web inspection equipment triggers alerts and notifications to operators. This immediate feedback allows for prompt corrective action, reducing the production of defective prints.

Integration with Printing Equipment

The web inspection systems are designed to work in tandem with many types of printing equipment, such as flexographic, offset, and digital printers. The interface allows a smooth workflow and easy incorporation into existing production processes.

Data Logging and Reporting

The web inspection machine often includes data logging capabilities for each print job, recording inspection results and defect data. Detailed inspection reports provide important insights into production quality, allowing for data-driven decision-making and process changes.

User-friendly Interface

Modern web video inspection system frequently has user-friendly interfaces that make it easier for operators to establish and manage inspection settings. Intuitive dashboards and reporting tools improve usability and make interpretation of inspection results easier.

Advantages of a Web Inspection System for Printing and Label Quality

A web inspection system for printing and label quality provides several benefits that have a substantial impact on the efficiency, productivity, and reputation of the printing industry.

Enhancing Printing Quality

The primary advantage of a web inspection system is its ability to ensure consistent and high-quality prints. By detecting and identifying defects and imperfections in real-time, the system helps maintain precise print quality throughout the production process. This results in flawless prints with accurate colors, sharp images, and well-aligned registration, meeting the highest standards of excellence.

Waste Reduction and Cost Savings

Early detection of flaws and variations in the printing process decreases the output of defective prints and raw material waste. As a result, printing companies save money on materials, ink, and resources, enhancing production efficiency and overall profitability.

Improving Productivity and Throughput

The web inspection machine simplifies the printing process by providing real-time monitoring and automated flaw detection. It helps operators to discover and correct printing problems quickly, decreasing downtime and increasing production throughput.

Regulatory Compliance Support

A web inspection system is critical for guaranteeing compliance in businesses with severe regulatory standards for printing quality. Printing companies can prevent compliance concerns, potential recalls, and legal consequences by consistently creating prints that fulfill regulatory standards.

Reducing Rework and Reprints

Defective prints frequently necessitate rework or reprints, which can be time-consuming and expensive. Early defect detection in the web inspection system helps prevent the manufacture of faulty prints, decreasing the requirement for rework and reprints and preserving precious resources.

Enhancing Customer Satisfaction

Consistently high-quality prints increase consumer satisfaction, bolstering the reputation and brand image of the printing company. consumers who are satisfied are more likely to become loyal consumers, resulting in repeat business and positive word-of-mouth referrals.

Real-time Monitoring and Actionable Insights

The web inspection system delivers real-time monitoring and warnings, allowing operators to take corrective steps as soon as errors are found. Furthermore, the system provides extensive inspection reports and data analysis, which provide significant insights into production quality and prospective process improvement areas.

Faster Time to Market

The web inspection system allows printing companies to bring their products to market faster by minimizing the time spent examining and resolving faults. This manufacturing agility can provide a substantial competitive edge in fast-paced sectors.

Streamlined Quality Control

The web video inspection system automates the quality control process, decreasing the requirement for manual inspection and improving overall defect detection accuracy and dependability. It frees up quality control workers to focus on other vital activities, improving workflow efficiency even more.

Competitive Edge

Implementing a web inspection system for printing and label quality gives printing businesses provides a competitive advantage to printing companies. Businesses may stand out in a competitive environment by consistently delivering high-quality prints, satisfying customer expectations, and boosting overall efficiency.

Summary

The web inspection system for printing and label quality is a crucial tool for ensuring that each print meets the highest quality standards. Manufacturers can safely generate perfect prints and labels that leave a lasting impression on clients and fulfill the expectations of an ever-changing market by implementing this cutting-edge technology.