What are Advanced Print Inspection Techniques for Emerging Applications

As printing technology continues to evolve, industries are finding innovative ways to implement print inspection systems for emerging applications. These applications go beyond traditional packaging and labeling, extending into areas such as printed electronics, 3D printing, and security printing. Ensuring high-quality output in these specialized fields requires advanced inspection techniques capable of detecting minute defects, maintaining precision, and improving efficiency.

Table of Contents

Key Emerging Applications of Print Inspection

1. Printed Electronics

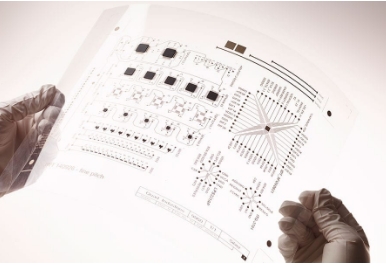

This technology involves creating flexible circuits, RFID tags, and sensors through advanced printing techniques. Any defect in these components—such as a break in a conductive trace or a misalignment—can affect performance, making accurate inspection essential. As printed electronics are increasingly used in consumer electronics, healthcare devices, and automotive applications, the need for high-resolution inspection systems capable of detecting micro-scale defects continues to grow.

2. 3D Printing

In this process, material is deposited layer by layer to create complex structures. Print inspection in this context ensures that each layer is accurately formed, detecting issues like layer misalignment, surface roughness, and internal voids. This is particularly important in industries like aerospace and medical manufacturing, where structural integrity is critical. Real-time monitoring and advanced imaging technologies help ensure that products meet stringent quality standards and design specifications.

3. Security Printing

Security printing represents another key emerging application, where inspection safeguards against counterfeiting and forgery. This involves the production of items like currency, passports, and authentication labels. Advanced inspection systems verify the accuracy of intricate security features, including microtext, holograms, and UV-visible elements. As threats of counterfeit products increase globally, print inspection technologies continue to evolve, incorporating machine vision and artificial intelligence to detect even the most subtle inconsistencies.

4. Pharmaceutical and Medical Packaging

In the pharmaceutical and medical sectors, print inspection ensures compliance with rigorous safety and regulatory standards. Accurate printing of barcodes, expiration dates, and unique serial numbers is crucial for patient safety and supply chain transparency. With regulations such as drug serialization mandates, automated print inspection systems verify and document every printed identifier, reducing errors and ensuring traceability throughout the product lifecycle.

5. Smart Packaging

This innovative packaging incorporates interactive features like QR codes, NFC tags, and augmented reality markers. Print inspection ensures these elements are correctly printed and functional, enabling better consumer engagement and product authentication. Industries such as food, beverage, and luxury goods increasingly rely on advanced inspection to maintain brand integrity and ensure user-friendly experiences.

6. Flexible and Stretchable Electronics

Used in wearable technology and medical sensors, these electronics require precise printing on diverse and often delicate substrates. Any defect in the printed circuitry can compromise performance and durability. As demand for wearable health devices grows, inspection systems must adapt to verify the quality of complex, flexible materials while maintaining high-speed production.

Challenges in Print Inspection for Emerging Applications

| Challenge | Description | Impact on Emerging Applications |

| High Print Inspection Precision Requirements | Need for micron-level accuracy to detect minute defects. | Essential for printed electronics and medical packaging. |

| Complex Substrates and Printing Materials | Inspection across diverse surfaces like flexible circuits. | Affects flexible electronics and smart packaging quality. |

| Real-Time Monitoring | Requirement for continuous inspection during production. | Critical for high-speed processes like 3D printing. |

| Detecting Invisible Features | Identifying hidden defects like UV markings or microtext. | Crucial for security printing and anti-counterfeiting. |

| Data Handling and Integration | Managing large volumes of inspection data efficiently. | Necessary for automated workflows and Industry 4.0 systems. |

| Adaptive Inspection Systems | Need to adjust for varying designs and printing methods. | Important for customizable products like smart packaging. |

| Environmental Variability | Maintaining accuracy under fluctuating conditions. | The key for outdoor labels in automotive and aerospace. |

| Cost Efficiency | Balancing advanced technology with operational costs. | Impacts affordability for small-scale or niche applications. |

Advanced Technologies Used in Print Inspection

1. Machine Vision Systems

The web inspection vision system for printing quality, use high-resolution cameras and advanced image processing to identify defects in real time. These systems capture and analyze each printed component, detecting issues such as misalignment, smudging, or missing details. Their ability to work at high speeds makes them especially valuable for industries like pharmaceutical packaging and consumer goods, where rapid and accurate inspection is crucial.

2. Artificial Intelligence (AI) and Machine Learning

These technologies enhance inspection accuracy by continuously learning from data. Unlike traditional methods that rely on predefined parameters, AI-driven systems can identify complex and previously unseen defects. This capability is particularly beneficial for industries producing variable designs, such as customized packaging and personalized print jobs. AI also reduces false positives and improves the system’s ability to distinguish between acceptable variations and actual flaws, increasing both efficiency and reliability.

3. Hyperspectral imaging

Hyperspectral imaging adds another layer of sophistication to print inspection by capturing data across a broad range of the electromagnetic spectrum. While conventional cameras only process visible light, hyperspectral systems detect subtle differences in material composition, making them ideal for inspecting invisible inks and embedded security features. This technology is especially crucial in security printing, where it ensures the authenticity of high-value documents like banknotes, passports, and official certificates.

4. 3D inspection technology

In applications where surface integrity is critical, 3D inspection technology is emerging as a vital tool. This method goes beyond traditional two-dimensional analysis to assess the height and texture of printed layers. It is particularly useful for inspecting products created through additive manufacturing (3D printing), where structural defects can compromise performance. It also supports industries that use raised printing or embossing, ensuring consistency across complex surfaces.

5. Optical Character Recognition (OCR) and Optical Character Verification (OCV)

For industries that rely on accurate text and data printing, optical character recognition (OCR) and optical character verification (OCV) are indispensable technologies. These systems interpret and verify printed alphanumeric data, ensuring that essential information—such as batch numbers, barcodes, and expiration dates—is correct and legible. This technology plays a crucial role in regulated industries like pharmaceuticals and food packaging, where even minor errors can lead to compliance issues and product recalls.

6. Infrared (IR) and Ultraviolet (UV) Inspection

The two techniques extend print inspection capabilities to areas invisible to the human eye. IR and UV systems detect hidden features and specialized coatings, which are often used in security applications to prevent counterfeiting. This technology is widely adopted in the production of sensitive documents and high-security labels, providing a reliable means to verify authenticity and protect against fraudulent replication.

7. Edge Detection and Pattern Matching

Edge detection and pattern matching are used for where print outputs are compared against reference templates. This technology identifies deviations in design and layout, ensuring precise replication of logos, brand elements, and critical visual features. It is particularly valuable in industries where brand consistency is paramount, such as consumer goods and luxury packaging.

8. Cloud-based Inspection Systems

These systems enable remote access to inspection data, facilitating real-time collaboration across multiple production sites. This innovation supports the integration of print inspection within Industry 4.0 frameworks, allowing manufacturers to analyze trends, optimize processes, and respond quickly to quality concerns.

Future Trends in Print Inspection for Emerging Applications

The future of printing inspection is being shaped by rapid advancements in technology and the growing need for higher accuracy, faster processes, and greater adaptability across industries.

- Integration of Real-time Inspection with Industry 4.0

Smart factories are incorporating advanced print inspection systems that connect with the Internet of Things (IoT) to enable real-time monitoring and predictive maintenance. This integration allows manufacturers to collect, analyze, and act on inspection data immediately, reducing downtime and enhancing overall production efficiency. In applications like pharmaceutical packaging, where traceability is crucial, real-time inspection ensures regulatory compliance while maintaining product quality.

- Fully Automated, Closed-loop Inspection Systems

These automated systems not only detect defects but also provide real-time feedback to the production line, allowing for automatic adjustments and corrections. This closed-loop approach reduces human intervention, improves process consistency, and enhances overall product quality. It is particularly beneficial in high-speed environments like flexible packaging and consumer goods printing, where rapid correction of defects is essential.

- Eco-friendly and Resource-efficient Inspection Methods

Future 100% printing inspection systems will focus on minimizing waste by detecting and correcting errors earlier in the production process. Additionally, innovations in inspection technology will support the use of sustainable materials by ensuring that eco-friendly substrates maintain print quality and integrity.

Final Thoughts

Print inspection for emerging applications is becoming more critical as industries demand higher precision, efficiency, and security. Innovations in AI, machine vision, and real-time monitoring are driving advancements in defect detection, ensuring that new printing technologies meet the stringent requirements of modern industries.