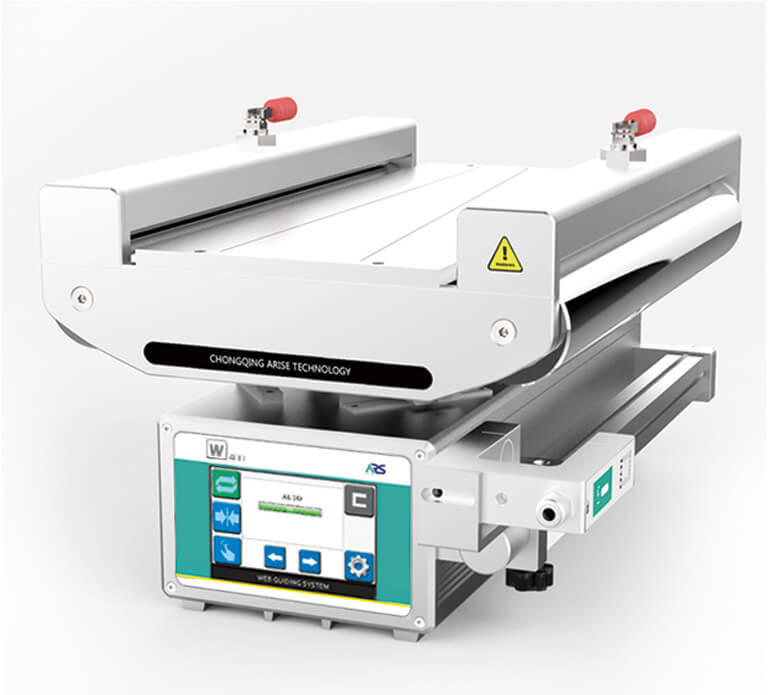

Basics of T500 Web Tension Controller

T500 is an automatic tension controller utilizing 16-bit high-precision AD sampling, featuring a rapid sampling time of 1us. Its sensor signal boasts high precision and swift speed. This controller can operate magnetic powder brakes and can interface with a single/double load cell, or function autonomously without a sensor. It finds wide application in industries such as papermaking, printing, packaging, and textile printing. The careful selection of a high-performance tension controller is pivotal in enhancing product quality, given that the accuracy of tension control significantly influences processing quality.

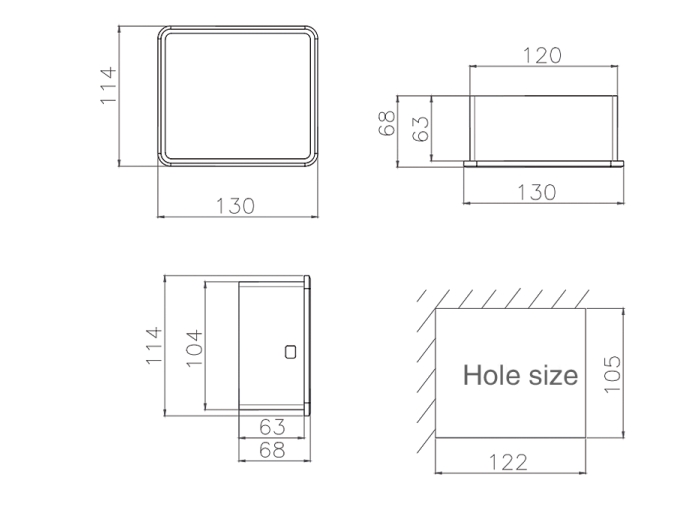

Dimensional Parameters of T500 Web Tension Controller

| Operating voltage | 24V±1% |

| Current consumption (excluding electric brakes) | 6.5A |

| Input signal | sine wave |

| Analog input end | 0-10V |

| Voltage value | 0-10V |

| Simulated output | DC 0-10V |

| Strain gauge power supply | 5V |

| Digital input | 6 input channels |

| 2 programmable channels | |

| Zero tension input | Relay normally open |

| Output voltage | 24V,maximum0.5A |

| Interface | Modbus RTU485 |

| Rated operating temperature | +5℃-55℃ |

| Relative air humidity | 15-95%((no-condensing) |

| Protection grade | IP54(with housing) |

| Dimensions (L*W*H) | 130X114X 68 |

Advantages Of T500 Web Tension Controller

- Precise Tension Control: Advanced algorithms ensure consistent and accurate tension regulation, reducing material defects and improving overall product quality.

- Wide Material Compatibility: Supports various materials, including paper, film, textiles, and foils, making it versatile for different industrial applications.

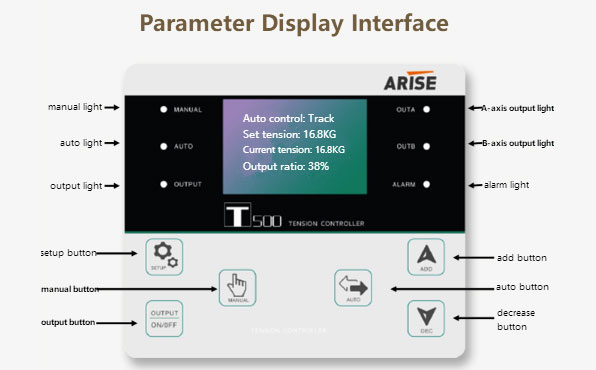

- User-Friendly Interface: Intuitive controls and real-time monitoring simplify setup and operation, enhancing user efficiency.

- Enhanced Productivity: Automatic adjustments minimize downtime and ensure smooth operation, increasing throughput and operational efficiency.

- Improved Process Stability: Real-time feedback ensures stable tension throughout production, preventing issues like wrinkles, stretching, or breakage.

- Durable and Reliable: Built with high-quality components to withstand demanding industrial environments, ensuring long-lasting performance.

- Cost-Efficiency: Reduces material waste and downtime, saving costs while maximizing resource utilization.

- Versatile Integration: Compatible with a wide range of machinery and production lines, offering flexibility in deployment across industries.

- Energy Efficiency: Optimized control systems reduce energy consumption, contributing to sustainable operations.

- Comprehensive Support: Backed by reliable technical support and service, ensuring smooth implementation and long-term performance.