Why Choose Web Tension Controller

During the uncoiling, processing, and winding of coil materials, it’s crucial to maintain tension to prevent stretching, wrinkling, breakage, or irregularities. Implementing web tension control enhances consistency, thereby reducing rewind defects. With a web tension controller, coil material tension can be effectively managed, enabling higher-speed operation of production machinery while minimizing waste and significantly improving efficiency.

Web tension control is primarily utilized during unwinding, intermediate processing, and rewinding stages. Proper tension control is essential during both unwinding and rewinding to ensure coil materials are maintained at the required tension levels throughout each process, thereby facilitating smooth and accurate production operations.

Application Videos Of Web Tension Controller

Basics of T1000 Web Tension Controller

T1000 is a fully touch screen automatic tension controller employing a 32-bit high-precision AD sampling method with a rapid sampling time of 1us. It excels in signal accuracy and speed, capable of driving various components such as magnetic powder brakes, motors, and pneumatic brakes. The controller offers compatibility with single/double tension sensors, pendulum arm potentiometers, and more. Moreover, it can autonomously perform internal arithmetic even in the absence of a sensor.

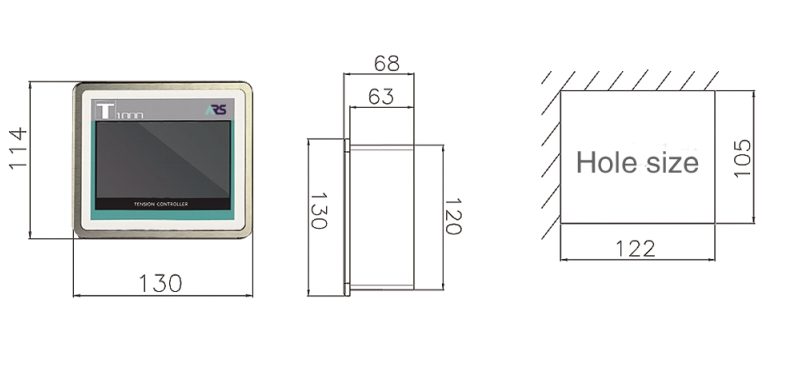

Dimensional Parameters of T1000 Web Tension Controller

| Operating voltage | 24V±1% |

| Current consumption | 0.2A |

| Sensor | 2 channels |

| Bridge supply voltage | 5V |

| Measuring cycle time | 1ms |

| Analog output | 2 outputs-10~+10V |

| 1 outputs0-10V | |

| 4-20mA | |

| Digital input | 6×passive |

| Digital output | 1×passive, short-circuit, short-circuit protected |

| Output voltage | 24V,maximum500mA |

| Rated operating temperature | +5℃-55℃ |

| Relative air humidity | 15-95%((no-condensing) |

| Protection grade | IP54 |

| Dimensions (L*W*H) | 113X67X 130mm |

Advantages Of T1000 Web Tension Controller

1. The tension calibration process is straightforward, delivering precise tension measurement alongside high stability and reliability.

2. It accepts input signals from single or dual sensors, accommodating a wide range of tension sensors.

3. Utilizes PID control to maintain operations without tension overshoot.

4. Features a metal shell with robust anti-interference capabilities, ensuring spark-free operation.

5. Automatic tension control requires just a few key presses, making it the simplest controller to operate.