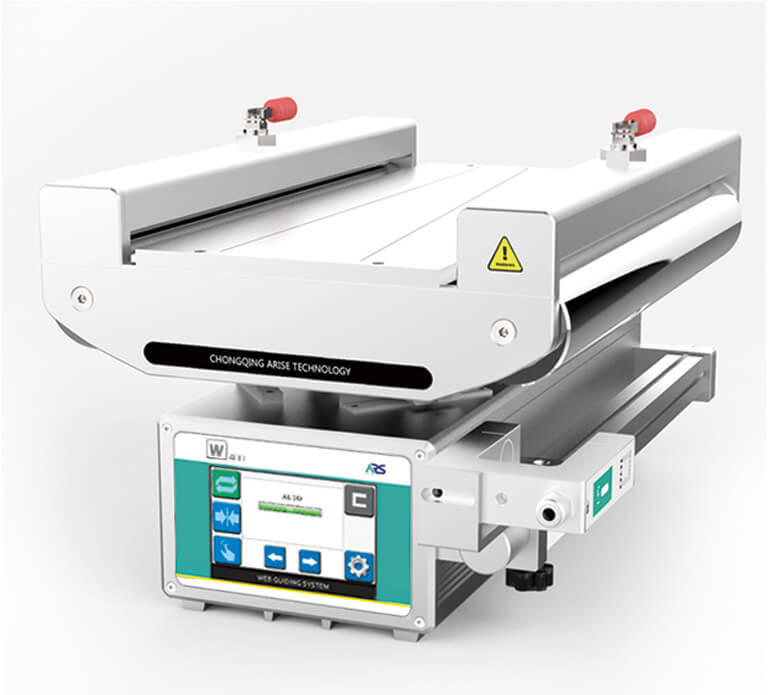

W200 Type Web Guide System

Models: W200

Brand: Arise

Why Choose Arise W200 Web Guide System

The Arise W200 all-in-one web guide system is ideal for use on narrow web materials, particularly in the label, non-woven, and packaging industries. This web guide equipment integrates advanced technology to ensure accurate material handling, reducing waste and improving productivity. Available in multiple sizes, the all-in-one web guiding system can be tailored to meet specific requirements. It is ideal for managing narrow web materials with exceptional reliability and performance.

Technical Parameter of Arise W200 Web Guide System

| Precision | <±0.1mm(Depends on material) |

| Error frequency | Maximum 8Hz |

| Rated adjustment stroke LU 160mm/200mm | ±15mm |

| Rated adjustment stroke LU 250mm/300mm | ±20mm |

| Rated adjustment speed on discharge roller | 100mm/s |

| Material tension NB160/200mm | Maximum 200N |

| Material tension NB/250/300/350/400/450mm | Maximum 300N |

| Roller diameter | 40/60/80/100mm |

| Ambient temperature | +5℃ ~+55℃ |

| Relative air humidity | 15~95%(no-condensing) |

| Rated operation voltage | 24VDC |

| Rated range | 20~28VDC(fluctuated) |

| Rated range in use | 100~240V,50/60Hz |

| Current consumption | Maximum 4.5ADC |

| Interface | External manual /automatic |

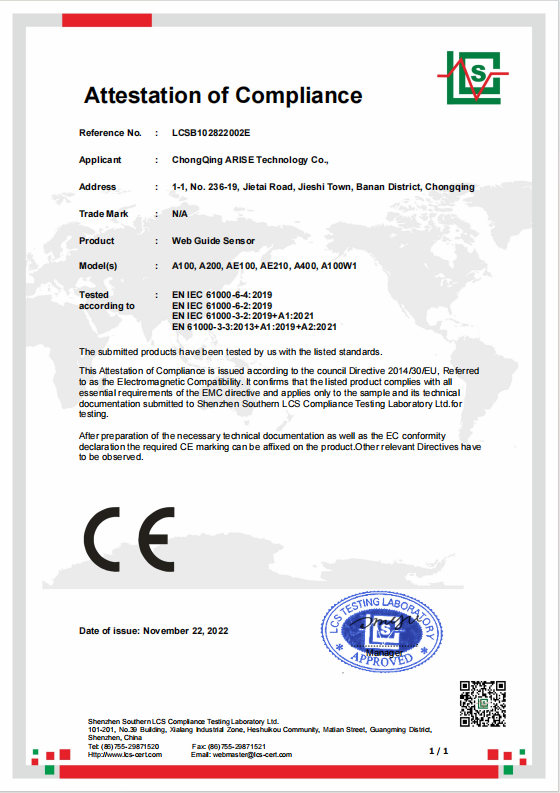

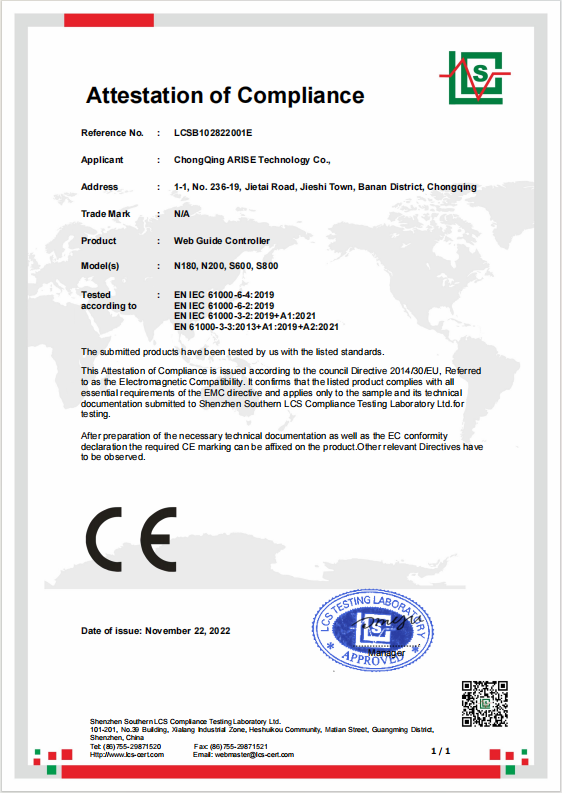

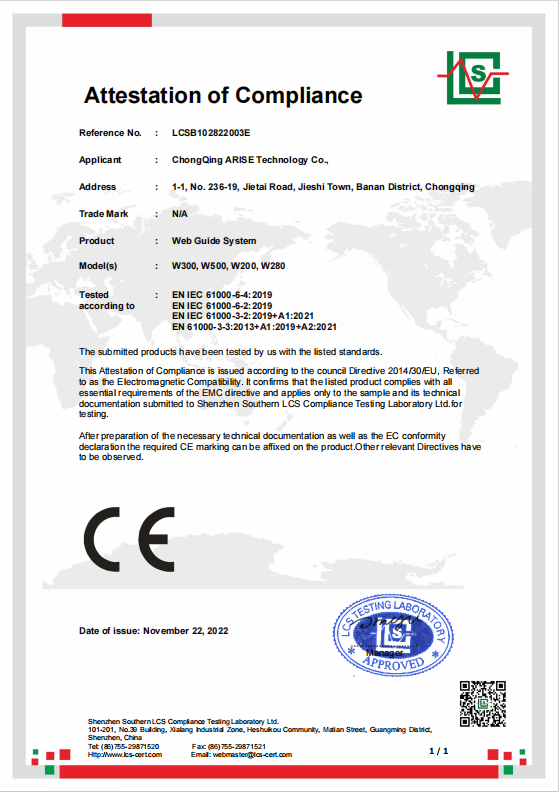

| Certification | Meet the CE standard |

| Protection grade | IP54 |

How to Install the W200 Web Guide System

| Step | Action |

| 1. Preparation | Review installation manual Gather tools and equipment Ensure a clean, clear workspace |

| 2. Mounting | Position the system on the production line Secure with mounting brackets and hardware Verify alignment with the web path |

| 3. Connecting Components | Connect sensors to controller input ports Attach actuators to output ports Ensure secure and correct connections |

| 4. Power and Data | Connect to a suitable power source Establish data connections with control/monitoring systems |

| 5. Calibration | Power on the system Follow the instructions of the web guide system manufacturer for calibration Adjust sensor positions and sensitivity Test actuators for correct response |

| 6. Testing and Fine-Tuning | Run a trial with web material Adjust sensor settings, actuator responses, and controller parameters Ensure accurate web guidance and alignment |

| 7. Final Inspection | Perform a thorough inspection of all components Check for misalignment, loose connections, or mechanical issues Confirm readiness for full-scale production |

How to Operate the W200 Web Guide System

| Step | Description |

| 1. Initial Setup | Power on the system Connect to the internet (Wi-Fi/Ethernet) |

| 2. User Interface | Home Screen: Access primary functions, quick links, and recent searches Navigation Bar: Find Home, Search, Categories, and Help Search Bar: Enter keywords to find guides |

| 3. Search Guides | Enter keywords in the search bar Apply filters to narrow results Select a guide to view in detail |

| 4. Use Categories | Browse categories from the navigation bar Explore subcategories Access popular guides |

| 5. Customize Preferences | Update profile information Adjust settings (language, theme, notifications) Save frequently used guides |

| 6. Help & Support | Access FAQs, user manuals, and tutorials Contact support via messaging, email, or phone for assistance |

| 7. Maintain System | Enable automatic updates Regularly backup data Perform routine maintenance |

Customized Roller Length in Arise W200 Web Guide System

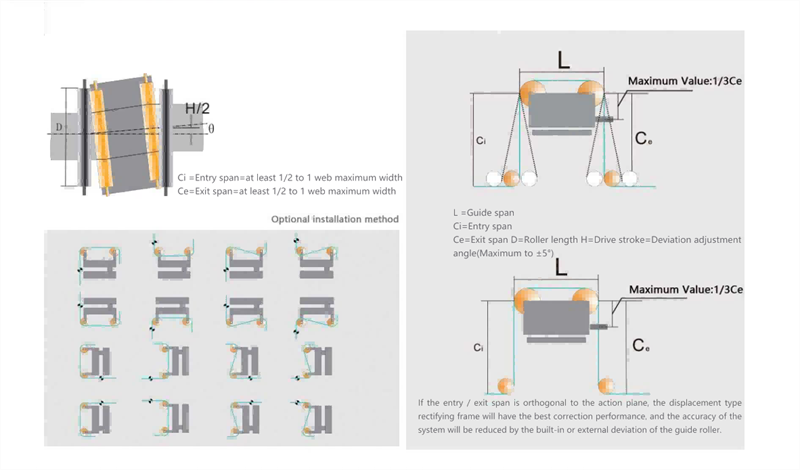

Customized roller length in a web guide system refers to the ability to tailor the dimensions of rollers used in guiding webs or continuous materials through production processes. This customization ensures optimal alignment, tension control, and handling of web materials such as paper, film, foil, or textiles. By adjusting the roller length to match specific application requirements, manufacturers can enhance system performance, reduce material waste, and improve product quality. Customized rollers can be designed to accommodate different web widths, weights, and material properties, leading to more efficient and precise web guiding solutions.

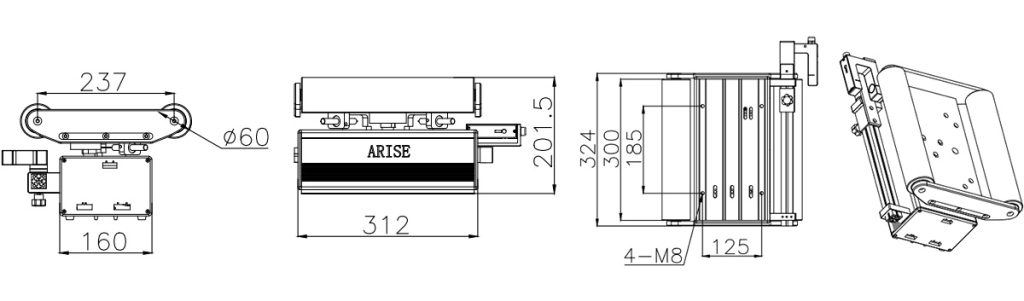

| Model Number Mounting | Hole Size | Roller Length | Body Length | Roller Frame Length |

| 160 | 115mm | 160mm | 189mm | 176mm |

| 200 | 185mm | 200mm | 312mm | 224mm |

| 250 | 185mm | 250mm | 312mm | 274mm |

| 300 | 185mm | 300mm | 312mm | 324mm |

| 350 | 285mm | 350mm | 412mm | 374mm |

| 400 | 285mm | 400mm | 412mm | 424mm |

| 450 | 385mm | 450mm | 512mm | 474mm |

| 500 | 385mm | 500mm | 512mm | 524mm |

| 600 | 485mm | 600mm | 612mm | 624mm |

| 700 | 585mm | 700mm | 712mm | 724mm |