Useful Tips Shared About Web Tension Controller

Whether the web tension control is stable will directly affect the quality of the product. If the tension is insufficient, the coil materials will drift during operation, and the finished paper will be wrinkled after slitting and rewinding. Web tension controller refers to the instrument which can permanently control the tension of the coil materials when conveyed on the machine. This controller must be effective for any speed of the machine, including machine acceleration, deceleration and uniform speed, even in the case of an emergency stop. It should also be able to ensure that the slit is not damaged.

Why Choose Web Tension Controller?

In many industries, winding control problems are often encountered. For example, in the production process of coil materials, the unwinding and winding tension of the coil materials is very important to the quality of the product. For this reason, constant tension control is required. That is to make the product receive good tension during the winding process and keep it unchanged from beginning to end. The stability of the tension control is directly related to the quality of the slitting product. If the tension is too large, it will cause the tensile deformation of the processed material, if the tension is too small, the stress between the layers of the coiled material will be deformed, resulting in uneven winding and affecting the processing quality.

How Does The Web Tension Controller Work?

The tension controller is a kind of equipment that can permanently control the tension of the material belt when it is transported on the equipment. Using this equipment can well maintain the operating speed of the machine, and can not affect production in an emergency. So, how does this device work?

The web tension controller mainly works through the coil. Coil magnetostatic powder clutch and magnetic powder brake are automatic devices that can control the input current and change the output. When the coil is not energized, the input shaft rotates, the magnetic powder is pressed on the inner wall of the clamp ring under the action of centrifugal force, and the output shaft does not contact the input shaft. At this time, it is in an idle state. When the coil is energized, the magnetic powder generates a magnetic link under the action of the magnetic lines of force, so that the output shaft and the input shaft become rigid bodies and rotate, and slippage occurs when overloaded. So as to achieve the purpose of transmitting torque.

Methods Of The Web Tension Control

1. Manual Control

Constantly adjust the torque of the clutch or brake during rewinding, discharging or the process to obtain the required tension, which requires the user to check the tension of the coil materials at any time and adjust the output torque at any time. If pneumatic is used for brakes or clutches, the manual tension controller can directly select precision pressure regulators, which can save a certain amount of equipment costs, but it is only suitable for some low-speed compound machines, extruders, textile machinery and other occasions where tension control requirements are not high.

2. Semi-automatic Method

The method adopts the ultrasonic principle to automatically detect the coil diameter for adjusting the tension of the coils. The tension controller is essentially a semi-closed loop system. It can not only automatically measure the coil and control the torque output, but also has the functions of buffer start, anti-loosening and inertia compensation. The implementation cost of this scheme is low, so the method is widely used in mid-range machinery.

3. Fully automatic Method

This method is to measure the tension of the coil by a web tension sensor, and then the controller automatically adjusts the clutch or brake to control the tension of the coils. This method is a fully closed-loop tension control. In principle, this solution can reflect the change of tension in real-time, so the control accuracy is the highest. Therefore, some high-end finishing mills, high-speed slitting machines and other metallurgical applications adopt fully automatic tension controller.

Full Automatic Web Tension Controller -T500/T1000

What is the full automatic web tension controller

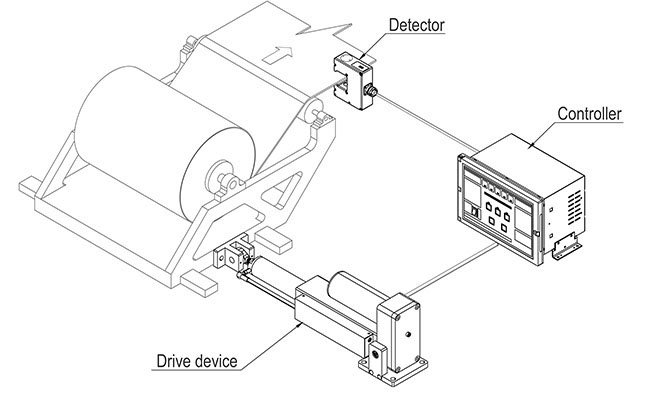

The automatic web tension controller is a high-precision, multi-functional, fully digital tension controller, which is combined with a tension sensor to form a closed-loop system. By receiving the signal transmitted by the tension sensor, after the internal PID calculation processing, the actuator is adjusted to automatically control the winding or unwinding tension of the materials. It performs high-precision tension control on the coils.

The full-automatic web tension controller has a large control range, high precision, strong anti-industrial interference ability. It can be used in conjunction with tension sensors, magnetic powder brakes or clutches, electronic control converters, torque motors, and frequency converters. It is widely used for tension control in printing, packaging, textile printing and dyeing industries.

T500/T1000 Web Tension Controller

T500/T1000 web tension controller is manufactured by Arise Technology which is specialized in research and development, production and sale of web guiding products & accessories such as web guide sensor, web guide controller, web guide actuator, etc with advanced photoelectric, CCD, color sensitivity and ultrasonic technology. The automatic T500/T1000 controller provides high accurate tension control with simple & stable operation, easy installation.

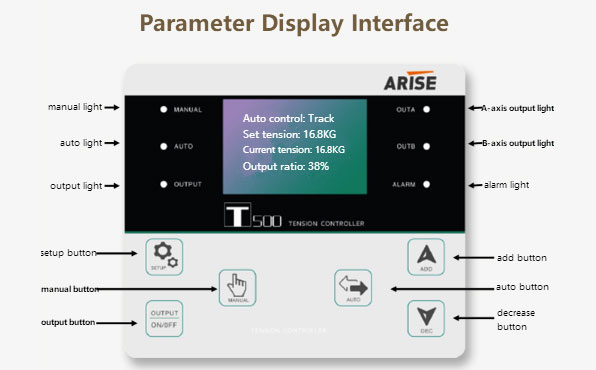

T500 web tension controller adopts 16-bit high-precise AD sampling for l us sampling time. The sensor has high signal precision and high speed. It can drive a magnetic powder brake. The controller can be connected with single/double pressure sensors.

T1000 is the first web tension controller to adopt a full touch screen. It adopts 32-bit high-precision AD sampling with 1us sampling time. The sensor provides a high precision signal with high speed and can be applied in conjunction with magnetic powder brakes, pneumatic brakes, electric motors, etc. It can be calculated automatically without a sensor.

Advantages Of T500/T1000 Web Tension Controller

1.It adopts 16-bit or 32-bit high-speed CPU with a humanized design, easy operation.

2. Using the PID algorithm without overshoot, the tension control is fast and stable.

3. Receive single/dual sensor input signals, adapt to various tension sensors

4. Dual 24V/4A output, which can directly drive two brakes/clutches.

5. It can output 0-10V, 4-20mA drive inverter or servo motor.

6. Easy installation and debugging with a simple tension calibration process.

7.Metal shell with strong anti-interference capacity without sparks

8. Parameter password protection to prevent misoperation.

9. Highly stable tension measurement.

Wiring Notices Of Automatic Web Tension Controller

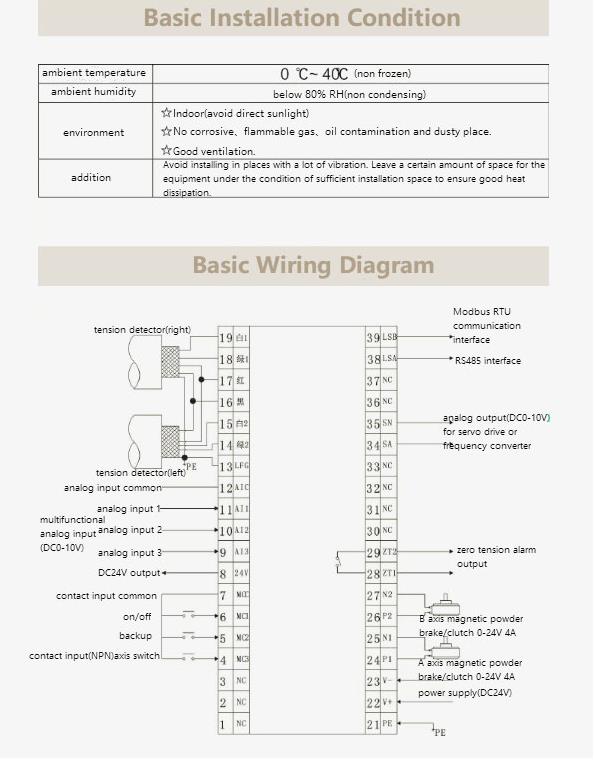

1. Weak wires such as the input signal wire, switch input and output terminals, the output power supply should be kept away from strong wires like the instrument power wire and power supply wire to avoid signal interference.

2. Kindly be noted that weak current terminals such as input signals, switch input and output terminals, and output power supply must not be connected to strong currents, otherwise, the entire controller will be burned.

3. Connect the tension sensor signal according to the correct wiring diagram. If you need to connect two tension sensors, you must pay attention to the polarity of the signal not to be wrong, otherwise, the displayed measurement value will be inaccurate.

4. If only a single tension sensor is connected, the input terminal which is not connected to the tension signal must be short-circuited.

Summary

Tension control is important for product quality. Web tension controller provides a high precision control with a simple adjustment. The full automatic T500/T1000 web tension controller can ensure continuous, accurate tension control of various coil materials in all kinds of production processes.