The Revolutionary Power of Maintenance-free Web Guiding Solutions

Table of Contents

In industries such as printing, packaging, and textiles, precise web guiding systems are essential to ensure smooth, efficient, and accurate operations. Traditionally, web guide systems have required regular maintenance and manual adjustments, leading to downtime, reduced efficiency, and increased costs. However, the advent of maintenance-free web guiding solutions is transforming the industry by providing more reliable, efficient, and cost-effective alternatives.

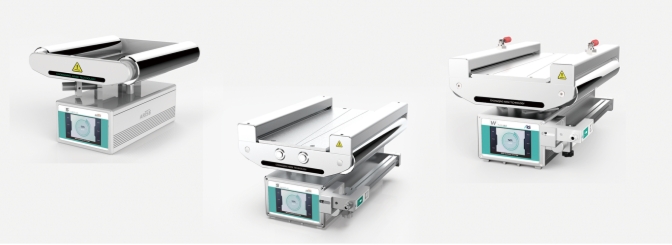

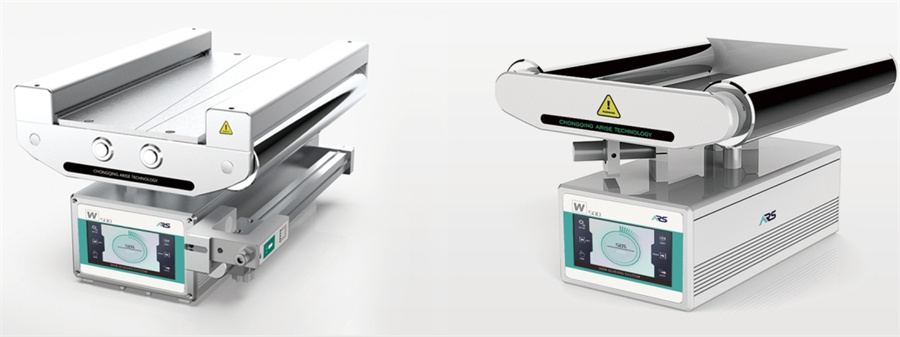

What are Web Guiding Systems

A web guiding system is a critical component in processing machines that ensures continuous, precise alignment of the web material. This is achieved through a combination of sensors, actuators, and mechanical components that detect any misalignment in the web and automatically correct it by adjusting rollers or tension. These systems are used across various sectors, including printing presses, converting lines, slitting machines, and coating processes.

The Need for Maintenance-Free Solutions in Web Guiding System

Conventional web guide systems often suffer from wear and tear, friction, and misalignment over time, leading to increased maintenance requirements. Common issues include:

- Mechanical wear: Constant motion of rollers, motors, and other moving parts can lead to mechanical failures and misalignments.

- Sensor degradation: Over time, sensors that track web position can degrade or malfunction, requiring recalibration or replacement.

- Unscheduled downtime: Frequent maintenance and adjustments can result in costly downtime, reducing overall productivity.

To overcome these challenges, maintenance-free web guiding solutions are becoming increasingly important. These web guiding control systems not only improve operational efficiency but also reduce the need for human intervention, thereby minimizing the risks of downtime and errors.

Key Features of Maintenance-Free Web Guiding Solutions

Maintenance-free web guiding solutions offer a cutting-edge approach to optimizing material alignment during high-speed processing. Their design focuses on durability, precision, and minimal intervention, making them ideal for various industries such as printing, packaging, textiles, and converting.

1. Advanced Non-Contact Sensors

Maintenance-free systems utilize non-contact web guide sensors such as laser, ultrasonic, or optical sensors to monitor the position of the web material.

- High Accuracy: Detects even the slightest misalignments.

- Durable Performance: Eliminates wear and tear associated with physical contact.

- Environmental Adaptability: Functions reliably in challenging conditions, including dust, heat, and moisture.

2. Self-Adjusting Mechanisms

Equipped with automatic feedback loops, these systems can correct misalignments in real time.

- Precision Control: Ensures consistent web alignment.

- Hands-Free Operation: Reduces reliance on manual adjustments.

- Error Reduction: Minimizes the risk of defects and waste.

3. High-Durability Materials

Components like rollers, bearings, and guide elements are constructed from advanced materials.

- Low-Friction Coatings: Ceramic-coated or self-lubricating materials minimize wear.

- Corrosion Resistance: Ideal for environments with high humidity or chemical exposure.

- Extended Lifespan: Designed to endure long-term use without degradation.

4. Intelligent Control Systems

Advanced web guide control systems incorporate smart web guide controllers for monitoring and optimization.

- IoT Connectivity: Enables remote monitoring and predictive maintenance.

- Data Analytics: Provides insights into performance and identifies potential issues early.

- Adaptive Adjustments: Optimizes system parameters automatically based on material and speed changes.

5. Low Energy Consumption

These web guiding systems are engineered for energy efficiency, ensuring sustainable operations.

- Optimized Power Usage: Reduces energy consumption without compromising performance.

- Cost Savings: Lowers operational costs over time.

6. Vibration-Free Operation

Maintenance-free web guide solutions feature smooth and balanced motion.

- Stable Web Alignment: Minimizes material oscillation during high-speed processes.

- Enhanced Precision: Improves product quality by reducing misalignment variability.

7. Modular Design for Seamless Integration

Most compact web guide systems are built with a modular framework.

- Easy Integration: Fits into existing production lines without extensive modifications.

- Flexibility: Accommodates various material widths and production speeds.

- Scalability: Can be upgraded as production needs evolve.

8. Predictive Maintenance Features

Though termed “maintenance-free,” these systems offer tools to preemptively address potential issues.

- Condition Monitoring: Sensors track component health in real time.

- Alerts and Notifications: Operators are informed of anomalies before they escalate.

Applications of Maintenance-free Web Guiding Solutions

This chart highlights the versatility of maintenance-free web guiding solutions across various industries, emphasizing their role in improving precision, reducing waste, and enhancing overall production efficiency.

| Industry | Application | Benefits |

| Printing | Ensures precise alignment of paper or film during printing. | Reduces misprints, improves quality, and minimizes material waste. |

| Packaging | Maintains alignment of packaging films on high-speed lines. | Enhances sealing accuracy, reduces downtime, and improves production efficiency. |

| Textiles | Guides fabric during processes like weaving, dyeing, and coating. | Prevents wrinkles, ensures uniform treatment, and reduces waste. |

| Converting | Aligns materials like paper, film, and metal sheets during slitting or laminating. | Achieves precise cuts, consistent quality, and minimal material loss. |

| Plastic Film Manufacturing | Aligns thin plastic films during extrusion and coating processes. | Prevents material stretching and ensures consistent thickness and coating quality. |

| Metal Processing | Guides thin metal strips in rolling, cutting, or coating operations. | Ensures precise alignment, reduces defects, and optimizes production speed. |

| Pharmaceuticals | Aligns blister packs or labels during packaging processes. | Improves product consistency and adheres to stringent quality standards. |

| Food Processing | Aligns materials such as flexible packaging and wrapping films. | Enhances package integrity, reduces waste, and ensures compliance with hygiene standards. |

| Battery Manufacturing | Maintains alignment of electrode and separator films during assembly. | Improves battery performance and ensures high-precision production. |

| Laminating | Ensures proper alignment of layers during the lamination process. | Prevents layer misalignment, reduces defects, and ensures a smooth finish. |

Considerations in Implementing Maintenance-free Web Guiding Solutions

This chart provides a structured approach to implementing maintenance-free web guiding solutions, ensuring the system meets both current and future operational needs.

| Category | Consideration | Impact/Benefits |

| System Compatibility | Ensure the web guiding solution aligns with existing production line configurations. | Minimizes integration costs and operational disruptions. |

| Material Properties | Evaluate the type, thickness, and elasticity of the web material. | Optimizes sensor performance and alignment accuracy. |

| Operating Environment | Assess environmental conditions such as dust, temperature, and humidity. | Selects durable materials and components suitable for harsh conditions. |

| Precision Requirements | Define the level of alignment accuracy required for the application. | Ensures the system meets quality standards without overengineering. |

| Production Speed | Confirm the solution can handle the speed of the production process. | Maintains consistent alignment during high-speed operations. |

| Energy Efficiency | Evaluate the power consumption of the system. | Reduces operational costs and supports sustainability goals. |

| Automation Integration | Check compatibility with IoT and automation platforms. | Enables remote monitoring, predictive maintenance, and data analytics. |

| Cost of Implementation | Calculate upfront costs, including installation and potential downtime. | Ensures return on investment aligns with operational goals. |

| Maintenance-Free Durability | Confirm the system’s ability to operate without regular maintenance over an extended period. | Reduces labor costs and enhances productivity. |

| Vendor Support | Evaluate the availability of technical support and training from the supplier. | Ensures smooth installation and long-term reliability. |

| Scalability and Flexibility | Verify whether the system can accommodate future production changes or material types. | Future-proofs the investment and supports business growth. |

In summary, maintenance-free web guiding solutions represent a significant advancement in industrial automation, offering a reliable, cost-effective, and efficient alternative to traditional web guide systems. Through minimizing downtime, reducing operational costs, and enhancing production efficiency, these web guiding control systems are helping businesses stay competitive in fast-paced industries. With their ability to seamlessly integrate with modern smart manufacturing setups, the maintenance-free web guide solutions are becoming an essential component for industries aiming for sustainable growth and high-quality outputs.