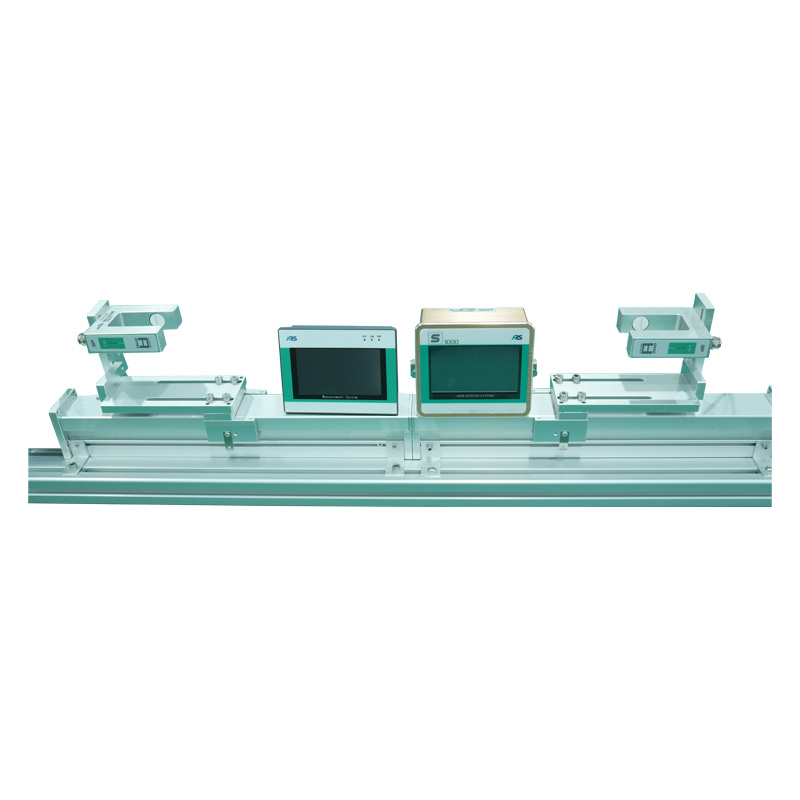

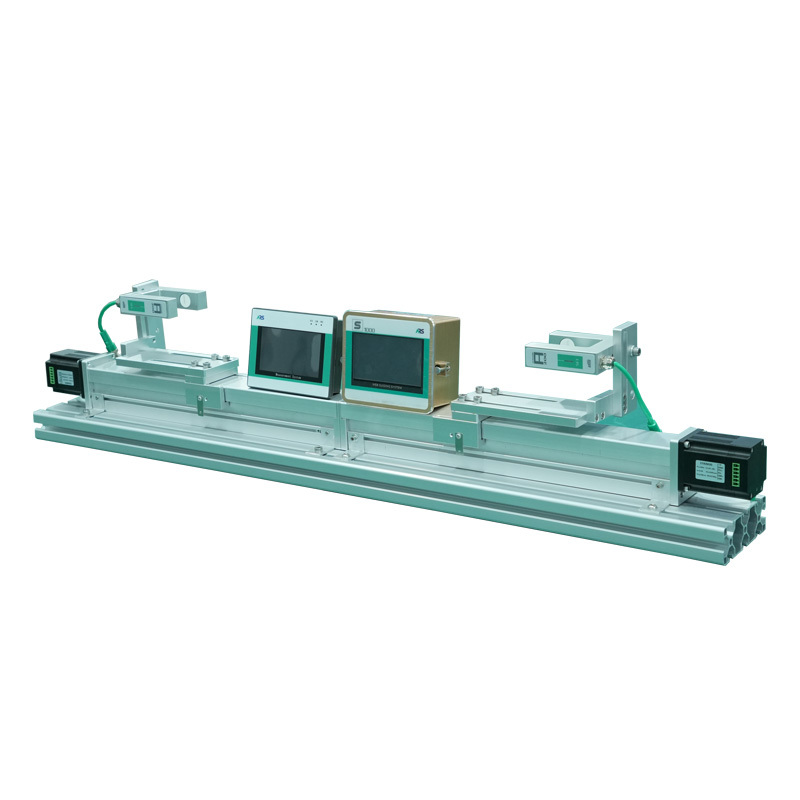

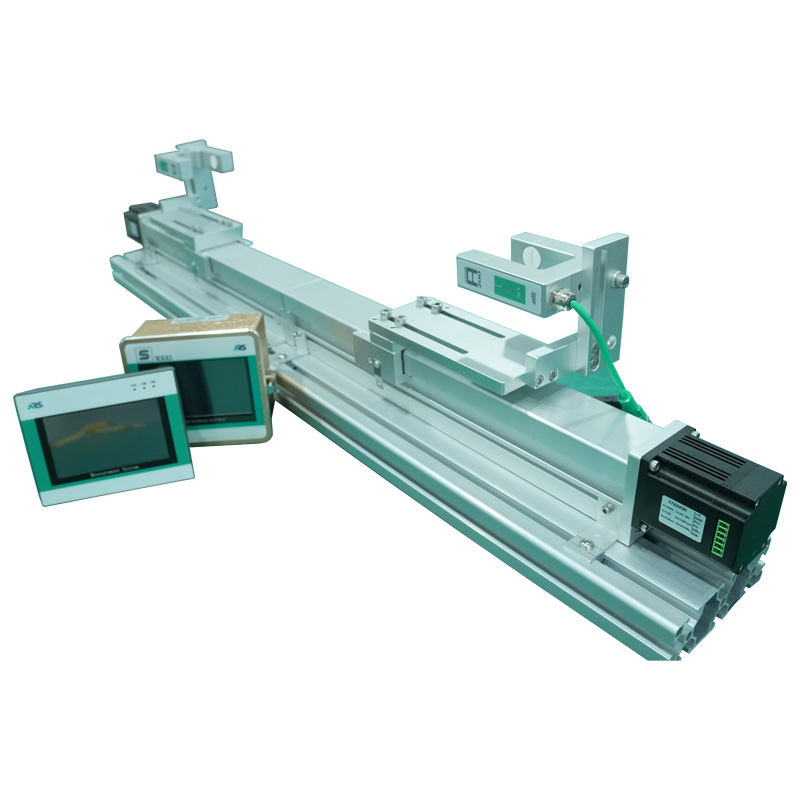

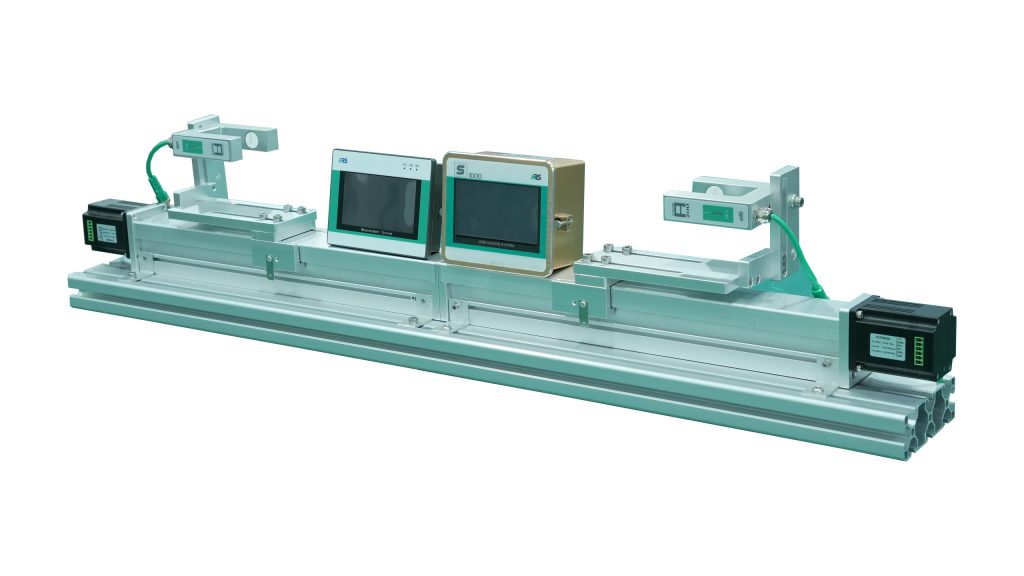

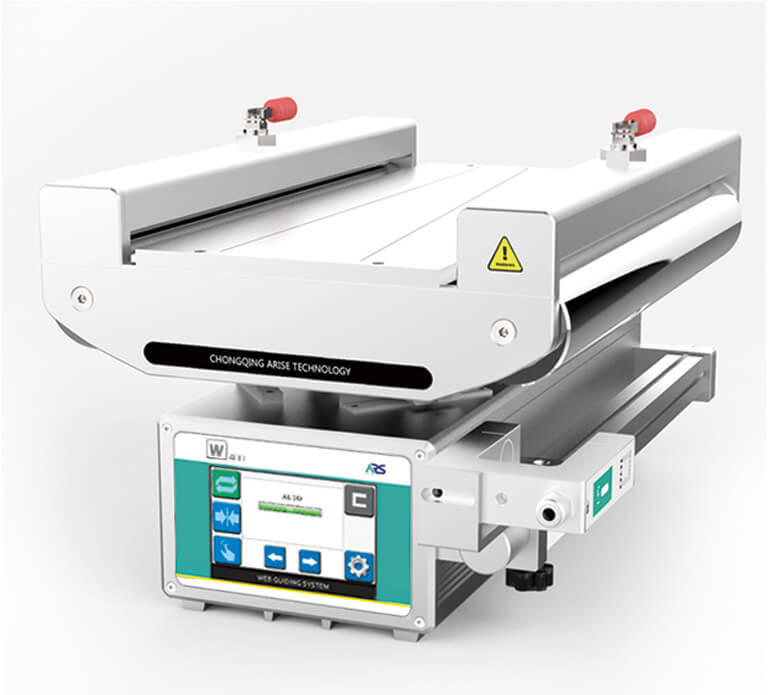

S1000 Pro Type Centering Web Guide System with Width Measurement

Models: S1000 Pro

Why Choose S1000 Pro Type Centering Web Guide System

S1000 Pro is a high-performance web guide system for centering guidance with width measurement functions. It is specially designed to improve production line efficiency and product quality. S1000 Pro type web guiding machine is suitable for printing, packaging, textile, steel, and other industries and can effectively reduce materials waste and improve production efficiency

Working Videos of S1000 Pro Type Centering Web Guide System

How Does S1000 Pro Type Centering Web Guide System with Width Measurement Work

Core Components and Functions

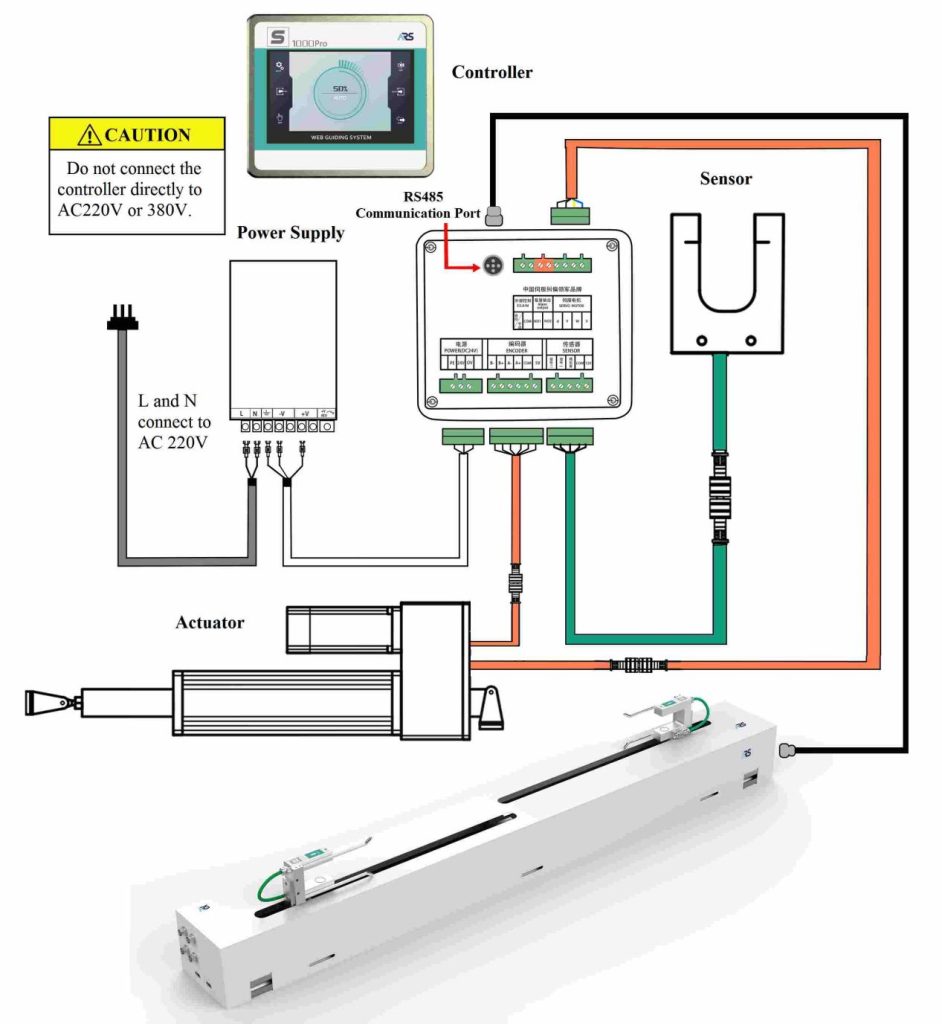

| Component | Function |

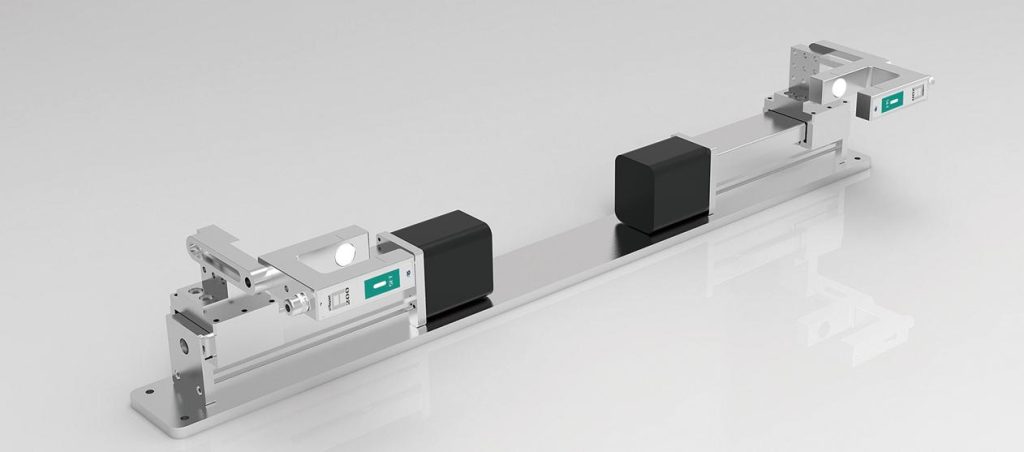

| Edge Sensors | Detect the position of the web’s edges using optical or ultrasonic technology. Provides continuous feedback on lateral position. |

| Motorized Actuators | Adjust the guide rollers based on sensor input to center the web. Correct any lateral deviations in real time. |

| Controller | Processes sensor data, calculates deviations, and sends commands to actuators to adjust the web’s position. Provides system integration. |

| Dual-Edge Width Sensors | Measure the distance between the left and right edges of the web to monitor and calculate web width in real time. |

| Display/Interface | Provides real-time monitoring of the web’s position and width, and allows for calibration, configuration, and adjustments by the operator. |

Working Process

Web Positioning and Centering

- The web passes through the guide system.

- Sensors detect any lateral deviations from the centerline.

- The web guide controller calculates the deviation and adjusts the guide rollers via actuators to re-center the web.

- This process occurs continuously, ensuring precise alignment throughout the operation.

Width Monitoring

- The edge sensors detect the left and right edges of the web.

- The distance between these edges is calculated to determine the web width.

- The width data is displayed or transmitted for quality control and integration into process automation systems.

Technical Parameters of S1000 Pro Type Centering Web Guide System

| CPU | 32-bit dual-core (FPGA + ARM) |

| Operating Frequency | 210MHz |

| Motor | Closed-loop servo motor |

| Response Time | 0.02ms |

| Encoder | 1000-line imported encoder |

| Accuracy | 0.004mm |

| Motor Speed Control | Adjustable motor speed(automatic speed change) |

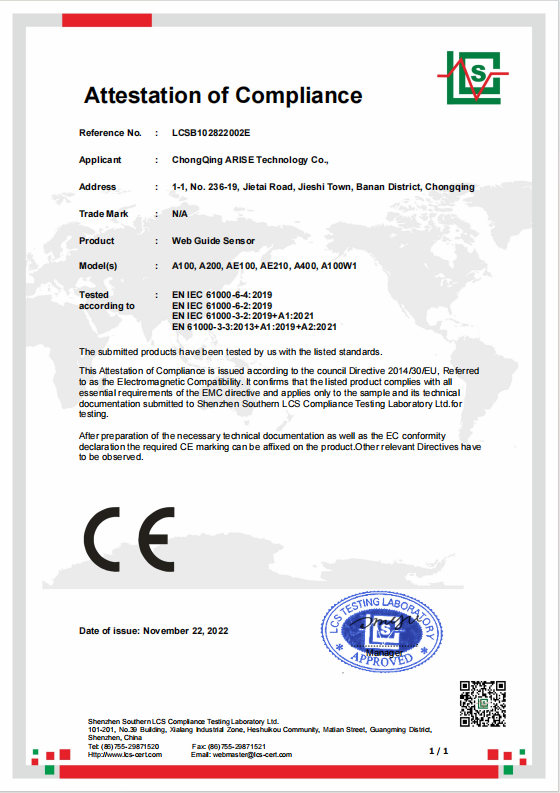

| Sensor Interface | Ultrasonic sensor, CCD line-tracking sensor |

| Interference Resistance | Metal shell, strong interference resistance |

| Commutation | Electronic commutation |

| Reliability | High |

| Maintenance Cost | Maintenance-free |

| Anti-static | 30,000V |

| Safety | Sparkless commutation |

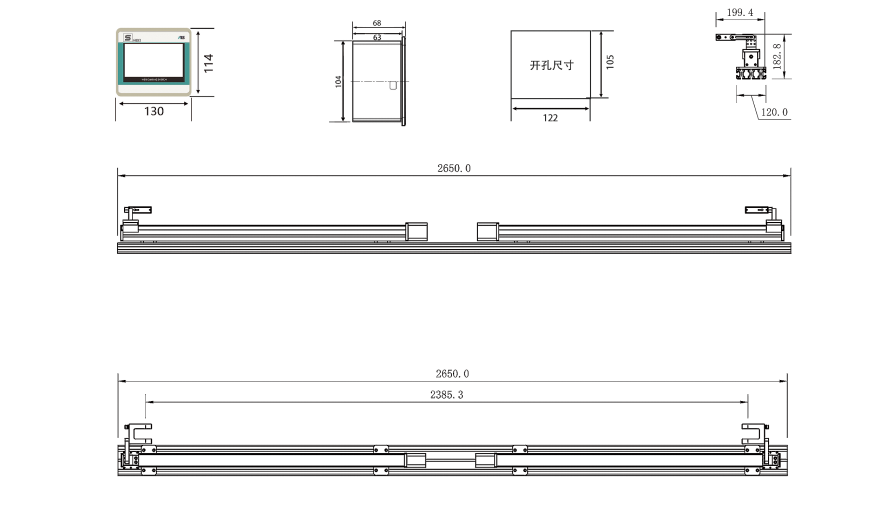

Specifications and Installation Dimensions of S1000 Pro Type Centering Web Guide System

|

Item |

Specifications |

|

|

Power supply |

Operating power input |

DC24V,with a current of at least 4A(150W recommended) |

|

|

Operating power output |

DC12V for sensors,with a maximum output current of 1A |

|

|

Motor output |

Control output PWA pulse for servo motor control |

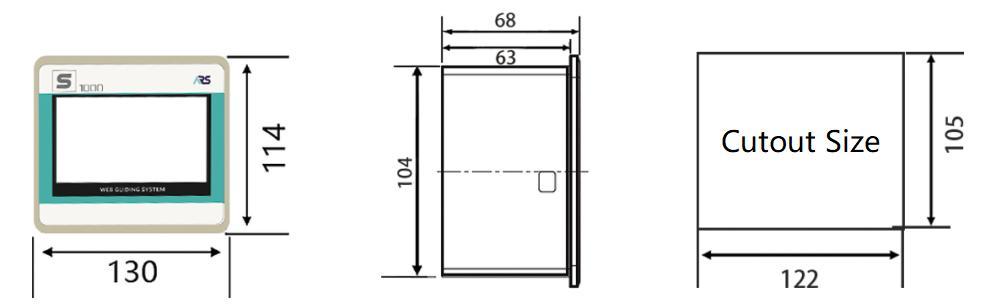

Exterior and Installation Dimensions