Retrofit Solutions for Web Guide Systems

Table of Contents

Over time, even the most robust web guide systems may require upgrades or modifications to keep up with evolving technology and operational demands. Retrofit solutions for web guide systems offer a cost-effective way to enhance efficiency, improve performance, and extend the lifespan of existing web guiding equipment.

Understanding Web Guide Systems

Web guide systems are designed to ensure that the material being processed stays correctly aligned during manufacturing. Misalignment can lead to defects, wasted materials, and increased downtime. These systems use sensors to detect the position of the web and make real-time adjustments to keep it on track. As technology advances, older systems may struggle to keep up with the precision and speed required by modern manufacturing processes.

Why Retrofitting Web Guide Systems is Essential

Retrofitting a web guide system is a strategic move that can significantly enhance the performance, efficiency, and longevity of existing machinery.

1. Enhanced Performance and Accuracy

- Improved Precision: Modern sensors and control systems offer greater accuracy in web alignment, ensuring consistent material handling and reducing defects.

- Real-Time Adjustments: Upgraded systems can make real-time corrections, minimizing the risk of errors and improving overall product quality.

2. Cost-Effectiveness

- Lower Upfront Costs: Retrofitting is typically more affordable than purchasing new equipment, allowing companies to improve their systems without a significant capital outlay.

- Reduced Downtime: Upgrading components rather than replacing entire systems minimizes downtime, ensuring continuous production and avoiding costly interruptions.

3. Extended Equipment Lifespan

- Modern Components: Retrofitting with modern, durable components can extend the life of the web guide system, delaying the need for a complete replacement.

- Preventive Maintenance: Upgrades often include predictive maintenance features, helping to prevent major failures and extend the operational lifespan of the equipment.

4. Energy Efficiency

- Reduced Power Consumption: Newer motors and control units are typically more energy-efficient, leading to lower operational costs and a reduced carbon footprint.

- Sustainability: By upgrading rather than replacing systems, companies contribute to sustainability by reducing waste and conserving resources.

5. Adaptability to New Requirements

- Meeting Modern Standards: As industry standards evolve, retrofitting allows existing systems to meet new regulatory and performance requirements without the need for complete replacement.

- Flexibility for New Materials: Upgraded systems can handle a wider range of materials and production speeds, providing greater flexibility in operations.

6. Improved Integration and Automation

- Seamless Integration: Retrofitted systems can be integrated into broader automation networks, enabling real-time data collection, monitoring, and control.

- Enhanced Productivity: Automation and improved control features lead to higher productivity by reducing manual intervention and optimizing the workflow.

7. Increased Competitiveness

- Staying Competitive: Retrofitting allows companies to keep pace with technological advancements without the financial burden of new equipment, maintaining their competitive edge in the market.

- Responding to Market Demands: Upgraded systems can quickly adapt to changes in market demands, enabling faster turnaround times and more efficient production.

Key Strategies for Retrofitting Web Guide Systems

1. Sensor Upgrades

- Advanced Sensing Technology: Replace outdated sensors with high-resolution ultrasonic edge sensors, or optical sensors for improved accuracy in detecting web alignment.

- Multi-Sensor Integration: Incorporate additional sensors along the web path to gather comprehensive data, enhancing alignment control and reducing errors.

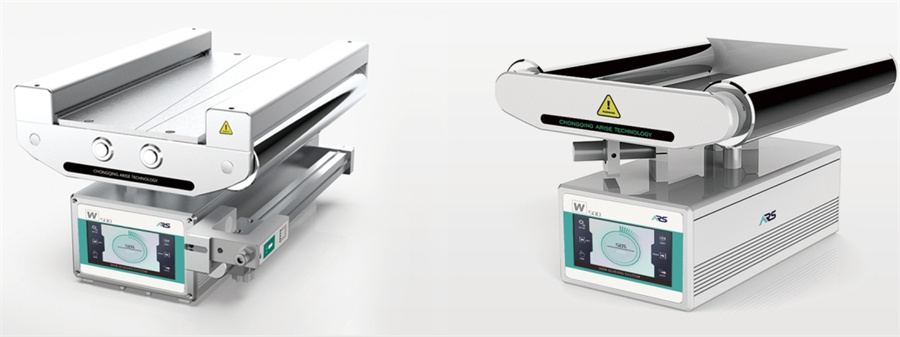

2. Control System Enhancements

- Modern Control Units: Upgrade to advanced web guide controller that offer faster processing, real-time adjustments, and user-friendly interfaces.

- Automation Integration: Integrate the control system with broader automation platforms for real-time monitoring, analytics, and predictive maintenance.

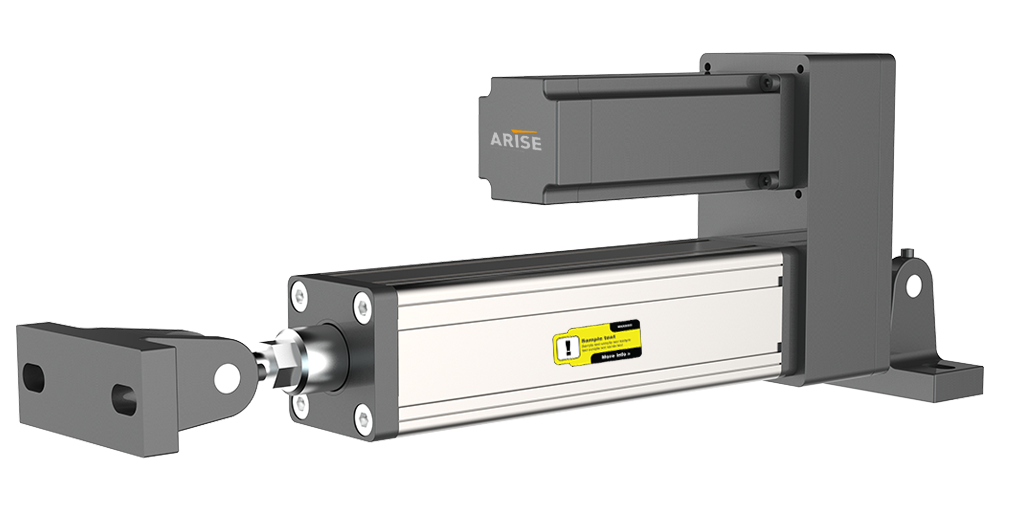

3. Actuator and Motor Upgrades

- Precision Actuators: Replace existing web guide actuators with precision models to achieve smoother, more accurate web movements, which helps prevent material damage.

- Energy-Efficient Motors: Install energy-efficient motors to enhance performance while reducing power consumption and operating costs.

4. Software Updates

- Advanced Algorithms: Implement software updates that utilize advanced algorithms for optimizing web tension and alignment in real-time.

- Remote Monitoring and Control: Retrofit with software that supports remote monitoring and control, allowing operators to manage the system from a distance, increasing flexibility, and reducing on-site adjustment needs.

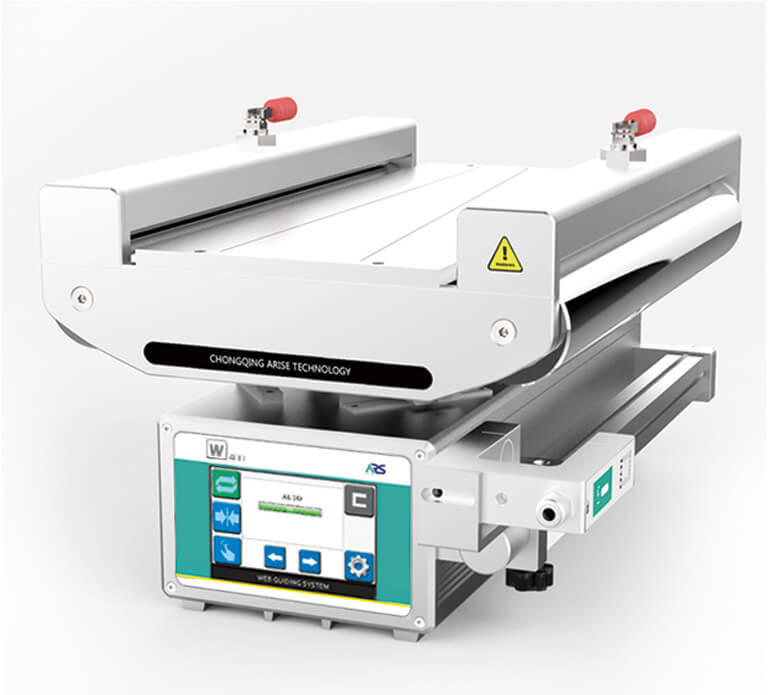

5. Mechanical Component Upgrades

- Roller and Guide Replacements: Upgrade to modern, low-friction rollers and guides to improve web handling and reduce wear on materials.

- Improved Tension Control Mechanisms: Retrofit with enhanced tension control systems to ensure consistent material handling, reducing the risk of web breaks and improving product quality.

Key Considerations for Successful Retrofitting Web Guide Systems

| Consideration | Description |

| Assessment of Existing System | Evaluate the current web guiding system’s performance, limitations, and compatibility with new technologies. |

| Compatibility with New Technology | Ensure that the retrofit components are compatible with the existing infrastructure and automation systems. |

| Budget and Cost Analysis | Analyze the cost-effectiveness of retrofitting compared to a complete system replacement. |

| Customization Needs | Identify any specific customization requirements for web guide control system based on the material, speed, and production environment. |

| Supplier Expertise | Choose experienced suppliers who specialize in retrofitting web guide systems and offer ongoing support. |

| Installation Downtime | Plan the retrofit to minimize production downtime and disruption. |

| Training and Support | Provide adequate training for operators and maintenance staff to ensure smooth integration and operation. |

| Future Scalability | Consider future production needs and ensure that the retrofit allows for easy upgrades and scalability. |

In summary, retrofitting web guide systems is a smart investment for manufacturers looking to stay competitive in an ever-evolving industry. Through upgrading sensors, control systems, actuators, and software, companies can achieve significant improvements in efficiency, product quality, and cost savings.