Web Inspection System For Printing and labeling Quality

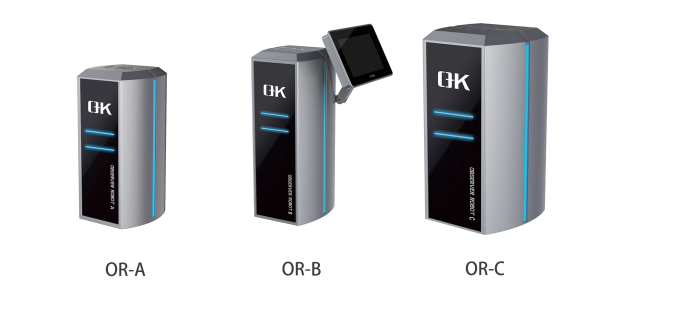

Models: OR-A, OR-B, OR-C, OR-D, OK4000

What Is Web Inspection System

When the printing press operates at high speeds, it surpasses the capability of the human eye to assess the printed image’s quality. Therefore, a printing quality inspection system becomes imperative to scrutinize static images. The web inspection system for printing employs innovative technologies and methodologies to transform rapidly moving images into “still” images that are perceptible to the human eye. These images can be magnified partially to detect minor print defects promptly, thereby enhancing the quality of printed products. Furthermore, it allows for the separate observation of images in real-time, facilitating comprehensive quality assessment.

OR-A, B, C Type Web Inspection System

The OR-A, B, C is a high-definition web inspection system equipped with a 5 mega/10 mega area scan camera for image capture. It boasts the capability to magnify images up to 25 times through post-processing while maintaining clarity. With shooting ranges of 55mm, 100mm, and 200mm, it caters to various monitoring needs. The web video inspection system operates at a maximum linear speed of 1200m/min, and it features automatic cruise functionality. It finds applications in printing, labeling, and other industries.

| Camera | 5 mega pixels High Resolution CMOS Camera | |

| Shooting range | OR-A | 60mmx45mm |

| OR-B | 100mmx75mm | |

| OR-C | 200mmx150mm | |

| Maximum speed | 1200m/min | |

| Supply Voltage | AC220V | |

| Guide rail length | 300mm-3000mm(Customizable) | |

| Display resolution | 24-inch HD display | |

| 1920×1080 | ||

| Operating Temperature Range | 0-50℃ |

OR-D Type Web Inspection System

OR-D introduces a high-definition full-frame web inspection system, designed to offer an expansive field of view for comprehensive imaging. This web inspection vision system accommodates long printing plate circumferences, ensuring the capture of the entire page circumference. Employing an 8k line array camera for image formation, OR-D guarantees high-resolution visuals. Through post-processing, images can be magnified up to 25 times while maintaining clarity. Its shooting range spans from 100mm to 2000mm, catering to a wide range of monitoring needs. With a maximum linear speed of 1200M/min, it ensures swift and efficient operation. Powered by a DC24V power supply voltage, OR-D web video inspection system finds applications in printing, labeling, and various other industries.

| Sensor type | CMOS |

| Pixel dimension | 7um |

| Resolution | 8192×3/8192×6 |

| Maximum horizontal scanning frequency | 8192x337Khz 10Bit |

| 8192x320Khz 10Bit | |

| Dynamic range | 65dB |

| Black &White/Colour | Colour |

| Mirror image | |

| Horizontal scanning frequency control |

Support horizontal mirroring maxi- mum free mode,internal software configuration cycle, encoder, ex- ternal pulse frequency |

| Weight | 456g |

Working & Installation Videos of Web Inspection System

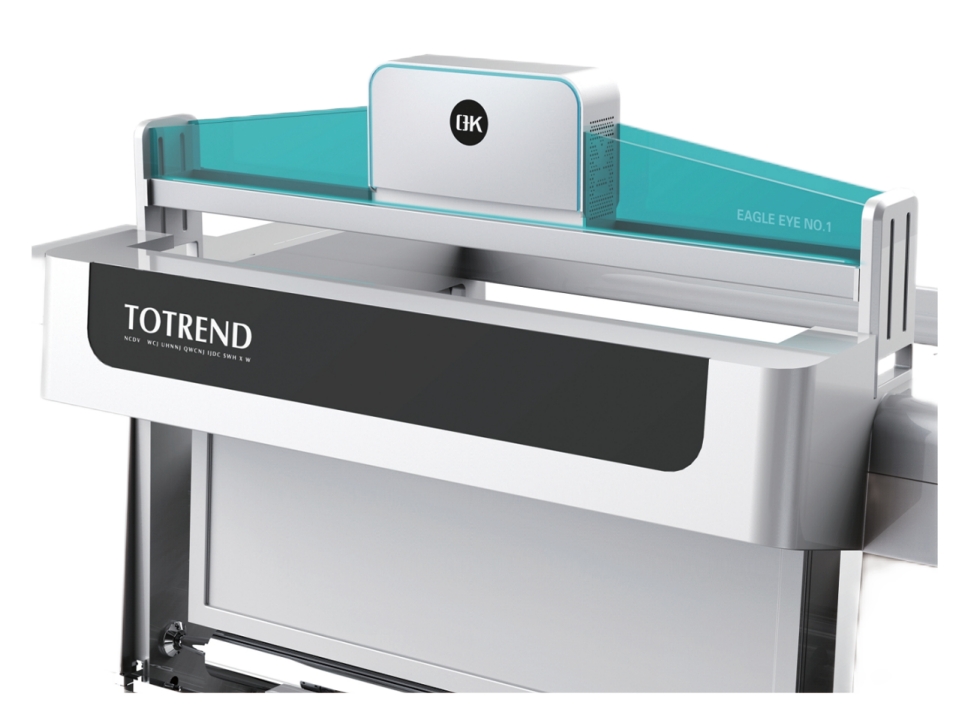

100% Web Inspection System for Printing Quality

The O+K visual web inspection system revolutionizes printing quality control with its seamless transition from full-width observation to full-width detection. By harnessing the latest image detection algorithms and special light sources, this system achieves a remarkable 100% full inspection rate. It excels in identifying a wide range of defects, including scratches, stains, depressions, bumps, and damage on rubber surfaces with unparalleled accuracy. With the web video inspection machine, manufacturers can ensure that every product meets the highest quality standards, minimizing defects and maximizing customer satisfaction.

System features (full range):

System Configuration:

| Subject | Parameter |

| Nominal lateral resolution | 0.15mm |

| Nominal longitudinal resolution | 0.15mm |

| Designed detection width | 10mm-600mm |

| Designed maximum speed | 450/min |

| Point defect detection accuracy | Defect area>0.2mm |

| Blade wire detection accuracy | Defect area>0.1mm*5mm |

| Overprint detection accuracy | Transverse>0.15mm longitudinal>0.25mm |