Printing Inspection Systems in Digital and Analog Printing Processes: Which One Effects Will be Better

Whether for commercial packaging, marketing collateral, or personal use, the quality and accuracy of printed materials are critical. Printing inspection systems are essential in both digital and analog printing processes to guarantee that each printed component meets the specified requirements. We shall investigate and compare the printing inspection systems employed in these digital and analog printing methodologies in this article.

Differences between Digital Printing and Analog Printing Using Printing Inspection Systems

Before diving into the specifics of printing inspection systems, it’s essential to grasp the fundamental differences between digital and analog printing processes.

Digital Printing

Technology: Inkjet and laser printing technologies are used in digital printing. It entails directly applying ink or toner to the printing surface without the use of printing plates or cylinders.

Flexibility: Digital printing is extremely versatile and can support variable data printing, allowing for the personalization of each printed piece.

Print Speed: Digital printers can produce prints at high speeds, making real-time inspection crucial.

Analog Printing

Technology: Offset, flexography, gravure, and letterpress are examples of analog printing technologies. Ink is transferred onto the printing surface using plates, cylinders, or screens in these methods.

Standardization: Analog printing is less adaptable to variable data and is often utilized for large print runs of identical items.

Setup: For color matching and registration, analog printing necessitates more manual setup and calibration.

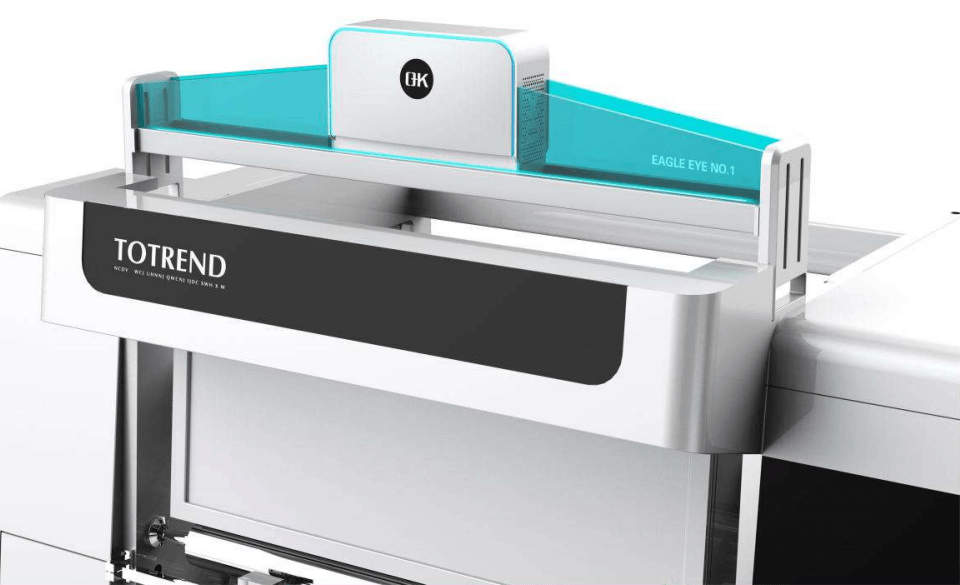

The Role of Printing Inspection Systems

Printing inspection systems are essential tools in today’s printing industry. They act as watchful quality control monitors, verifying the integrity of printed products and that they fulfill high quality standards. These technologies serve a multifarious role in ensuring that printed items not only appear attractive but also deliver information reliably and consistently, from color correctness to variable data verification.

Comparison of Printing Inspection Systems in Digital and Analog Printing Processes

The two types of printing processes differ significantly, which can have an impact on the design and performance of the inspection systems utilized. Let us now compare printing inspection methods in digital and analog printing processes.

1. Inspection Criteria

Digital Printing:

Color accuracy, registration (alignment of different colors or parts), and print quality (nozzle dropouts, streaks, or faults) are the primary concerns of digital printing inspection systems.

Analog Printing:

Color accuracy and registration are likewise checked by analog printing inspection systems, although other concerns such as plate wear, cylinder condition, and ink viscosity may need to be addressed.

2. Variable Data Handling

Digital Printing: Digital printing is ideal for variable data printing since it allows for the customisation of each printed piece. Printing inspection systems in digital printing often need to handle variable data and ensure that each piece matches the intended design.

Analog Printing: Analog printing processes are less flexible when it comes to variable data. Typically, they are used for high-volume print runs of identical materials.

3. Print Speed

Digital Printing: Digital printers can often produce prints at higher speeds compared to analog printing presses, making real-time inspection crucial.

Analog Printing: Analog printing presses may have slower production speeds, allowing more time for inspection during the printing process.

4. Setup and Calibration

Digital Printing: Setting up inspection systems for digital printers is often easier and requires less manual adjustment because digital printers have built-in controls for color and registration.

Analog Printing: Analog printing presses require more manual setup and calibration of the inspection systems to ensure precise color matching and registration.

5. Cost and Maintenance

Digital Printing: Because they are integrated with the digital printer and may have fewer moving components, digital printing inspection systems can be less expensive to set up and maintain.

Analog Printing: Because of the additional components required, such as web guide systems and tension control systems, inspection systems for analog printing may be more complex and expensive.

6. Waste Reduction

Digital Printing: By detecting faults early in the printing process, digital printing inspection devices can help save waste by minimizing the need to remove misprinted materials.

Analog Printing: Analog printing inspection systems help to reduce waste, but they are not as efficient as digital ones.

Conclusion

Printing inspection systems act as vigilant guardians of print quality, ensuring that the finished product meets or exceeds expectations. While printing inspection systems are beneficial to both digital and analog printing processes, each has its own set of requirements and obstacles.

Digital printing inspection systems excel at dealing with changeable data, are cost-effective, and are well-suited for high-speed printing. Analog printing inspection systems, on the other hand, require more human calibration and may be better suited for high-volume, uniform print runs.

Ultimately, the printing inspection system selected should be compatible with the unique needs of the printing process and the intended print quality. The goal, whether digital or analog, is the same: to create high-quality printed items that leave a lasting impact.