A printing inspection system is a specialized solution designed to monitor and evaluate the quality of printed materials and web materials in real-time. It uses advanced imaging technologies, such as cameras and sensors, to detect defects like misalignment, color deviations, smudges, missing elements, and incorrect barcodes. Widely employed across industries like packaging, pharmaceuticals, publishing, and manufacturing, these printing quality inspection systems help ensure accuracy, consistency, and compliance with standards, reducing waste and minimizing errors in high-speed production environments.

Web Inspection and 100% Printing Inspection System

How Does Print Inspection System Work

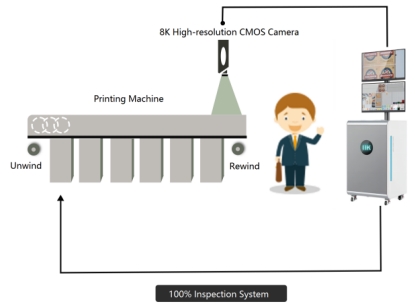

A print inspection system operates by using advanced imaging technologies, such as high-resolution cameras or sensors, to capture real-time images of printed materials during production. These images are then analyzed using sophisticated software equipped with pattern recognition and defect detection algorithms. The 100% printing quality inspection machine compares the captured images against predefined quality standards or reference templates to identify any anomalies, such as misalignments, color inconsistencies, or defects like smudges and missing elements.

Once an issue is detected, the system generates alerts or stops the production line to ensure defective prints are not distributed. By automating this process, printing quality inspection systems ensure high accuracy in high-speed printing environments.

Key Components

This chart provides a concise overview of the essential components that work together to ensure the efficiency and accuracy of a print inspection system.

| Component | Description | Role |

| High-Resolution Cameras | Advanced cameras that capture detailed images of printed materials in real-time. | Detects defects such as smudges, misalignment, and missing elements. |

| Lighting System | LED or other lighting setups that ensure even illumination of the printed material. | Enhances visibility of details, improving defect detection. |

| Image Processing Software | Sophisticated algorithms to analyze captured images for deviations or inconsistencies. | Identifies errors and flags anomalies automatically. |

| Sensors | Devices to measure print parameters such as color density, registration, and alignment. | Ensures consistent quality by monitoring key printing metrics. |

| User Interface | Control panels or software interfaces for system operation and configuration. | Allows operators to customize settings and monitor performance. |

| Feedback Mechanism | Systems that provide real-time alerts or stop production in case of critical defects. | Prevents waste by allowing immediate corrective actions. |

| Database/Storage System | Storage for inspection data, images, and analysis reports. | Enables traceability and quality audits. |

| Integration Module | Tools that connect the inspection system to production lines or ERP systems. | Facilitates seamless workflow integration and data sharing. |

| Reject Mechanism | Automated ejectors or markers that remove defective products from the production line. | Ensures only high-quality materials proceed further. |

Applications of Print Inspection System

This chart highlights the diverse use cases of print inspection systems across industries, showcasing their importance in maintaining quality, accuracy, and compliance.

| Application | Description | Industry | Benefits |

| Packaging Quality Control | Inspects packaging materials for alignment, color accuracy, and defects. | Food, Pharmaceuticals, FMCG | Ensures brand consistency and regulatory compliance. |

| Label Inspection | Checks for misprints, missing labels, or incorrect barcodes. | Retail, Logistics | Prevents labeling errors that could disrupt supply chains. |

| Security Printing | Verifies watermarks, holograms, and microprints in sensitive documents. | Banking, Government | Enhances anti-counterfeiting measures and document authenticity. |

| Commercial Printing | Monitors color fidelity and text alignment in brochures, flyers, and catalogs. | Advertising, Publishing | Ensures high-quality output for marketing materials. |

| Pharmaceutical Packaging | Detects defects in critical information like batch numbers and expiration dates. | Pharmaceuticals | Ensures patient safety and regulatory compliance. |

| Flexible Packaging Inspection | Checks for errors in films, laminates, and flexible substrates. | Consumer Goods | Ensures quality in lightweight and high-speed production materials. |

| 3D Print Inspection | Analyzes printed layers for consistency and surface flaws. | Manufacturing, Prototyping | Reduces material waste and ensures dimensional accuracy. |

| Textile Print Inspection | Monitors patterns, colors, and designs on printed fabrics. | Apparel, Home Textiles | Enhances fabric quality and minimizes production defects. |

| Metal and Foil Printing | Detects print quality issues on metal and foil surfaces. | Packaging, Industrial | Guarantees durable and clear markings in challenging environments. |

| Barcode and QR Code Verification | Validates readability and accuracy of printed codes. | Logistics, Retail | Improves inventory management and supply chain efficiency. |

Why Choose Arise as a Trusted Supplier of Print Inspection System

Arise stands out as a reliable provider of advanced print inspection systems, offering cutting-edge technology tailored to meet diverse industry needs.

Choose Arise for precision, innovation, and trusted expertise in printing quality and web inspection solutions.

- Advanced Technology: Arise leverages state-of-the-art imaging and detection technologies to deliver high-performance printing quality inspection systems that ensure flawless quality control.

- Industry Expertise: With extensive experience across industries like packaging, pharmaceuticals, and printing, Arise provides tailored solutions to meet unique operational requirements.

- Customization Options: Arise offers flexible and customizable systems to integrate seamlessly with your production line, enhancing efficiency without disrupting workflows.

- Comprehensive Support: From consultation and installation to maintenance and upgrades, Arise ensures a smooth experience with dedicated customer service.

- Proven Reliability: Known for delivering consistent, accurate, and durable systems, Arise has earned a reputation as a trusted partner in quality assurance.

- Cost-Effective Solutions: By reducing production waste and minimizing errors, the inspection systems provided by Arise help optimize costs while maintaining the highest quality standards.