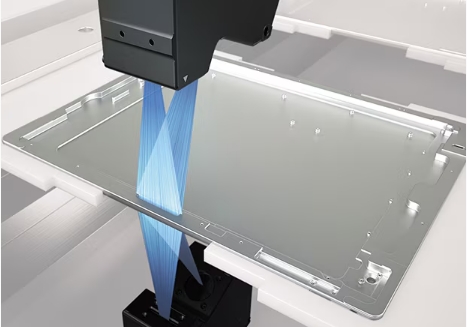

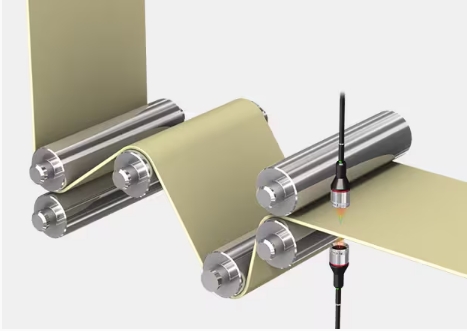

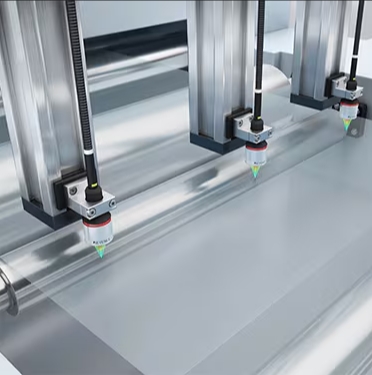

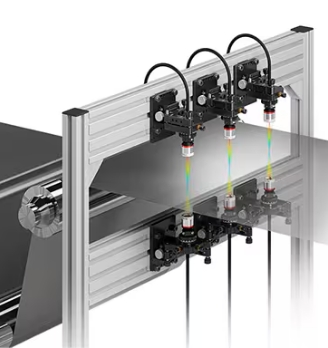

An in-line measurement system is a specialized technology used in manufacturing processes to perform real-time measurements of various parameters directly within the production line. This system typically consists of sensors, detectors, or probes integrated into the machinery or production equipment. It play a critical role in ensuring product quality, enhancing process efficiency.

As the product moves through the production line, the in-line measurement system collects data on key characteristics such as width, thickness, weight, color, or other quality-related attributes. The collected data is then analyzed and processed using software algorithms to assess product quality, identify deviations from specifications, and provide feedback for process control.

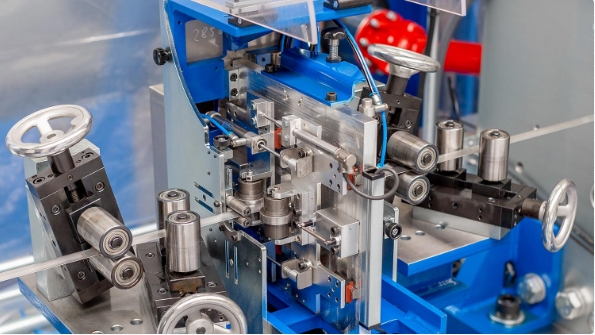

In-line Width/Thickness Measurement System

Applications of In-line Width/Thickness Measurement System

| Industry | Application | Benefits |

|---|---|---|

| Paper and Packaging | Quality Control, Production Monitoring | Ensures product consistency, reducing waste |

| Film and Foil Production | Thickness Uniformity, Process Optimization | Maintains material properties, improving production efficiency |

| Textile | Fabric Quality, Production Efficiency | Ensures design specifications, optimizing processes |

| Metal and Foil Rolling | Dimensional Accuracy, Waste Reduction | Achieves precise thickness, reducing material waste |

| Plastic Extrusion | Consistency, Process Control | Maintains uniform product quality, adjusting extrusion parameters |

| Automotive | Component Manufacturing, Quality Assurance | Ensures parts meet tolerances, enhancing product reliability |

| Electronics and Semiconductors | Precision Measurement, Process Improvement | Meets precise material requirements, improving performance |

| Construction and Building Materials | Material Consistency, Quality Control | Ensures industry standards, enhancing material quality |

Why Choose Arise In-line Width/Thickness Measurement System

Arise is a leading supplier in the field of industrial measurement systems, specializing in high-precision solutions for various manufacturing and production environments. Arise provides cutting-edge solutions for width and thickness measurement, web guiding, tension control, and more. Systems provided by Arise, are renowned for their accuracy, reliability, and ease of integration into diverse industrial processes.

Choosing the Arise In-line Width/Thickness Measurement System offers several key advantages for industrial operations that require precise and real-time measurement of material dimensions

- High Accuracy: The Arise system provides precise and reliable measurements of width and thickness, ensuring high-quality control and consistency in production.

- Real-Time Monitoring: It delivers continuous, real-time data on material dimensions, allowing for immediate adjustments to maintain optimal production conditions and prevent defects.

- Improved Efficiency: By integrating seamlessly into production lines, the Arise system helps streamline operations, reduce waste, and enhance overall efficiency by detecting and correcting deviations as they occur.

- Versatility: The system is suitable for a wide range of materials and industries, including paper, film, textiles, and metals, making it a versatile choice for diverse applications.

- Durability and Reliability: Designed for industrial environments, the Arise system is built to withstand harsh conditions and provide long-lasting performance with minimal maintenance.

- User-Friendly Interface: With an intuitive interface, the Arise system allows for easy setup, operation, and data analysis, reducing the need for extensive training and simplifying workflow management.

- Cost-Effective: By reducing material waste and enhancing product quality, the system helps lower production costs and improve return on investment.