How Web Inspection Systems are Applied in the Flexible Packaging Industry

Flexible packaging materials, such as plastic films, laminates, and pouches, are widely utilized due to their versatility, cost-effectiveness, and sustainability. However, maintaining the integrity and quality of flexible packaging materials is essential to prevent defects that could compromise product safety and brand reputation. To address this challenge, Web inspection systems have emerged as indispensable tools in this regard, offering comprehensive inspection capabilities throughout the production process.

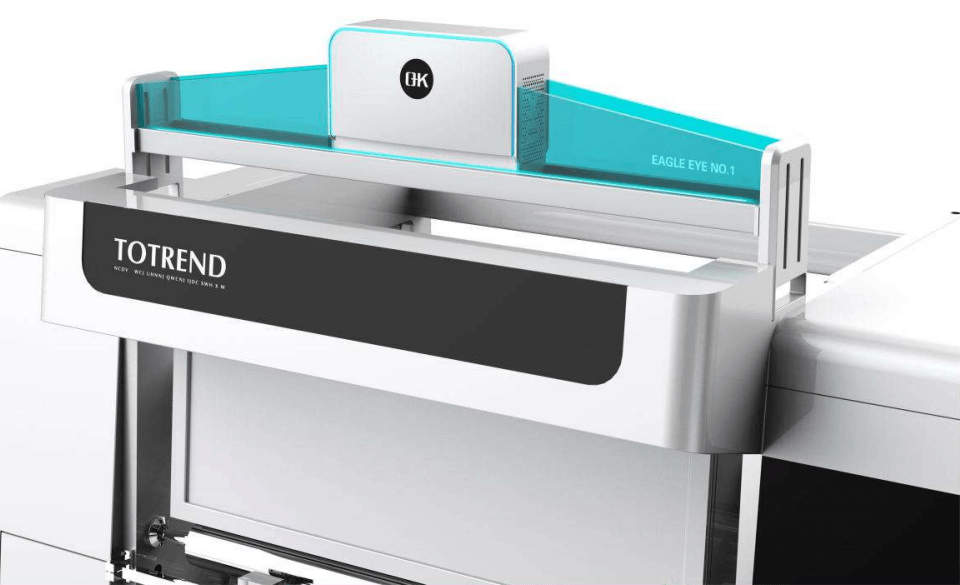

Understanding Web Inspection Systems

Web inspection systems are sophisticated equipment that continuously inspect materials as they go through a production line. These systems use cameras, sensors, illumination, and software algorithms to inspect many characteristics of the material, such as flaws, pollutants, print quality, and structural integrity. Web inspection solutions help firms to quickly discover and resolve errors, ensuring that only high-quality items reach the market.

Web Inspection Systems Applied in the Context of Flexible Packaging

1. Printing Inspection

- Web inspection systems are deployed to scrutinize printed flexible packaging materials for defects such as misprints, color variations, streaks, and missing or misplaced graphics.

- High-resolution cameras and advanced image processing algorithms detect imperfections with precision, ensuring that the printed packaging meets brand standards and regulatory requirements.

2. Lamination and Coating Inspection

- During the lamination and coating processes, web inspection systems assess the integrity of the layers, detecting defects such as delamination, bubbles, wrinkles, and uneven coating.

- By identifying these flaws early in the production cycle, manufacturers can take corrective actions to prevent material waste and ensure the structural integrity of the packaging.

3. Substrate Inspection

- Flexible packaging materials are often comprised of multiple substrates, including films, foils, and papers. Web inspection systems examine these substrates for defects like tears, scratches, and foreign particles.

- By maintaining the quality of individual substrates, manufacturers uphold the overall integrity and performance of the flexible packaging, safeguarding the packaged product during storage and transportation.

4. Slitting and Rewinding Inspection

- As flexible packaging materials undergo slitting and rewinding processes, web inspection systems monitor for defects such as edge irregularities, uneven tension, and splices.

- Real-time detection of these defects prevents roll-to-roll inconsistencies and ensures uniformity in the final packaging products.

5. Barriers and Seals Inspection

- Flexible packaging often includes barriers and seals to protect the contents from moisture, oxygen, and other external factors. Web inspection systems examine these seals for defects such as leaks, wrinkles, and incomplete seals.

- Maintaining seal integrity is critical for preserving product freshness and extending shelf life, particularly in industries like food and pharmaceuticals.

6. Regulatory Compliance

- Web inspection systems help manufacturers comply with regulatory standards and industry-specific requirements, such as FDA regulations for food contact materials or pharmaceutical packaging guidelines.

- By ensuring that flexible packaging materials meet regulatory specifications, manufacturers mitigate the risk of recalls, penalties, and reputational damage.

7. Data Analytics and Process Optimization

- Beyond defect detection, web inspection systems collect valuable data on production metrics, defect rates, and machine performance.

- By analyzing this data, manufacturers gain insights into production inefficiencies, enabling them to optimize processes, reduce waste, and enhance overall productivity.

Challenges and Solutions in Web Inspection Systems Applied in Flexible Packaging

| Challenges | Solutions |

| Material Variability | Develop adaptive algorithms for adjusting inspection parameters based on material properties.Incorporate multispectral imaging for comprehensive analysis across substrates. |

| High Production Speeds | Invest in high-speed cameras with rapid processing capabilities. Implement parallel processing and distributed computing architectures.Use advanced motion control systems for synchronization. |

| Complex Defect Detection | Utilize machine learning and deep learning algorithms trained on large datasets for printing inspection. Combine multiple inspection techniques for comprehensive analysis.Integrate vision inspection, spectroscopy, and thermal imaging. |

| Integration with Production Equipment | Collaborate with equipment manufacturers for standardized interfaces.Develop middleware solutions for seamless communication.Design modular systems for easy integration with diverse equipment. |

| Maintenance and Calibration | Implement automated calibration routines and self-diagnostic capabilities. Utilize remote monitoring and predictive maintenance algorithms.Provide comprehensive training programs for operators and maintenance personnel. |

| Operator Training and Expertise | Develop user-friendly interfaces with intuitive visualization tools. Implement augmented reality (AR) features for on-the-job guidance.Offer training programs to ensure proficient handling of the equipment. |

| Cost Considerations | Offer flexible financing options and leasing arrangements.Highlight long-term cost savings and return on investment (ROI).Emphasize benefits such as reduced material waste and improved efficiency. |

| Data Management and Analysis | Utilize cloud-based storage and analytics platforms for centralized data management.Implement advanced data analytics algorithms for actionable insights.Utilize predictive analytics capabilities for future trend analysis. |

Future Innovations in Web Inspection Systems Applied in Flexible Packaging

Incorporating these future advancements into web inspection systems used in flexible packaging will improve quality assurance while also driving efficiency, sustainability, and competitiveness in the packaging industry.

1. 3D Imaging and Analysis

- Future web inspection systems may incorporate 3D imaging technologies to provide enhanced depth perception and spatial analysis of flexible packaging materials.

- By capturing detailed surface topography and dimensional information, these systems can detect and characterize defects with unprecedented accuracy and precision.

2. Nanotechnology-enabled Inspection

- Nanotechnology-based sensors and imaging techniques could enable web inspection systems to detect ultra-fine defects and contaminants at the nanoscale level.

- These advancements will be particularly beneficial in industries where strict purity and cleanliness standards are paramount, such as pharmaceuticals and electronics.

3. Flexible Sensor Integration

- Integration of flexible and stretchable sensors directly into flexible packaging materials could enable in-line monitoring of structural integrity, barrier properties, and environmental conditions.

- These sensors can provide real-time feedback on packaging performance, shelf-life extension, and product freshness, enhancing quality control and consumer safety.

4. Augmented Reality (AR) Inspection Interfaces

- AR-enabled inspection interfaces could revolutionize operator training, visualization, and decision-making processes in flexible packaging production.

- Operators wearing AR headsets can overlay real-time inspection data onto the production line, enabling intuitive defect identification, troubleshooting, and quality assurance tasks.

5. Autonomous Inspection Systems

- Autonomous web inspection systems equipped with AI-driven algorithms and robotic actuators could perform end-to-end inspection tasks with minimal human intervention.

- These systems can navigate through complex production environments, adjust inspection parameters dynamically, and prioritize inspection areas based on production priorities and defect likelihood.

6. Blockchain-enabled Traceability and Authentication

- Web inspection systems may integrate blockchain technology to provide end-to-end traceability and authentication of flexible packaging materials throughout the supply chain.

- Each packaging unit can be assigned a unique digital identifier linked to inspection data, enabling transparency, anti-counterfeiting measures, and product authentication.

7. Quantum Sensing and Computing

- Quantum sensing technologies could revolutionize defect detection capabilities by leveraging quantum phenomena such as superposition and entanglement.

- Quantum-inspired algorithms and computing architectures can exponentially increase the processing power and sensitivity of web inspection systems, enabling rapid and accurate defect identification.

8. Self-healing Materials and Packaging

- Future flexible packaging materials may incorporate self-healing properties enabled by smart polymers, microcapsules, or nanomaterials.

- Web inspection systems can monitor the effectiveness of self-healing mechanisms in real-time, ensuring the integrity and longevity of the packaging throughout its lifecycle.

9. Predictive Maintenance and Reliability Engineering

- Advanced analytics and machine learning algorithms can enable predictive maintenance of web inspection systems, reducing downtime and optimizing performance.

- By analyzing historical data and sensor telemetry, these systems can anticipate equipment failures, degradation trends, and maintenance needs, enabling proactive interventions and reliability engineering strategies.

Conclusion

Web inspection systems play a vital role in ensuring the quality, safety, and compliance of flexible packaging materials in the modern manufacturing processes. By leveraging advanced technologies and real-time monitoring capabilities, these systems enable manufacturers to detect and rectify defects promptly. As technology continues to advance, web inspection systems will play an increasingly vital role in driving innovation and excellence in the packaging industry.