How to Integrate Tension Amplifiers into Web Tension Control System

Web tension control is crucial in industries that process materials like paper, film, foil, and textiles. Maintaining consistent tension ensures high-quality output, reduces waste, and optimizes production efficiency. Tension amplifiers play a pivotal role in web tension control systems by enhancing the accuracy and stability of tension measurements. This article explores the benefits and best practices for integrating tension amplifiers into web tension control systems.

Why Choose Tension Amplifiers Used in Web Tension Control System

Understanding Web Tension Control

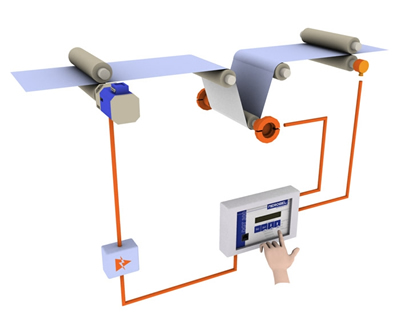

Web tension control refers to managing the force applied to a continuous web of material as it moves through various stages of production. Precise tension control prevents issues such as wrinkling, stretching, and tearing, which can compromise product quality and lead to increased waste. Effective web tension control systems often use a combination of sensors, amplifiers, and tension controllers to maintain the desired tension levels.

The Role of Tension Amplifiers

Tension amplifiers are devices that enhance the signals from tension sensors or load cells, converting mechanical force into precise electrical signals. These signals are then used by control systems to adjust and maintain the correct tension. Tension amplifiers are essential for accurate and reliable web tension control, especially in complex and high-speed production environments.

Benefits of Integrating Tension Amplifiers into Web Tension Control Systems

This chart provides a clear and concise overview of the various benefits offered by the integration of tension amplifiers into web tension control systems.

| Benefit | Description |

| Enhanced Accuracy and Precision | Provides high-resolution data for precise control, ensuring consistent product quality. |

| Improved Stability and Reliability | Enhances weak signals for consistent performance under varying conditions, reducing downtime. |

| Seamless Integration | Integrates with advanced control systems (PLCs, DCS) for real-time monitoring and adjustments. |

| Flexibility and Adaptability | Configurable to suit a variety of web materials and processing conditions, making it versatile. |

| Enhanced Product Quality | Maintains optimal tension levels to prevent issues like wrinkling and tearing, ensuring high-quality output. |

| Reduction in Material Waste | Minimizes defects and ensures uniform quality, leading to cost savings and more sustainable production. |

| Increased Production Efficiency | Allows for higher line speeds and more consistent operation, reducing manual adjustments. |

| Scalability for Future Expansion | Supports expansion without significant changes, allowing businesses to grow and adapt. |

| Enhanced Monitoring and Diagnostics | Built-in diagnostic features for continuous assessment and early detection of issues. |

| Long-term Cost Savings | Results in improved quality, reduced waste, and increased efficiency, leading to lower total costs. |

Considerations and Solutions for Integrating Tension Amplifiers into Web Tension Control Systems

Integrating tension amplifiers into web tension control systems involves a series of crucial considerations to ensure optimal performance, reliability, and efficiency. Addressing these considerations with appropriate solutions is key to achieving consistent web tension and maintaining high-quality production standards.

Considerations and Solutions

1. Compatibility with Existing Systems

- Consideration: Ensuring that tension amplifiers are compatible with the existing sensors, controllers, and actuators is critical for seamless integration.

- Solution: Conduct a thorough compatibility check of input and output specifications. Use tension amplifiers with configurable input ranges and multiple output options (e.g., analog, digital) to match existing system requirements.

2. Calibration and Maintenance

- Consideration: Regular calibration is essential for maintaining the accuracy of tension measurements. Maintenance routines help prevent performance degradation over time.

- Solution: Establish a calibration schedule based on manufacturer recommendations and operational demands. Implement routine maintenance checks to identify and rectify potential issues, ensuring that tension amplifiers function accurately.

3. Environmental Factors

- Consideration: Industrial environments often present challenges such as temperature fluctuations, humidity, and vibration, which can affect the performance of tension amplifiers.

- Solution: Select industrial-grade tension amplifiers designed to withstand harsh conditions. Look for features such as temperature compensation, rugged enclosures, and vibration resistance to ensure reliable performance in challenging environments.

4. Signal Quality and Interference

- Consideration: Electrical noise and interference can degrade signal quality, leading to inaccurate tension measurements.

- Solution: Utilize shielded cables and proper grounding techniques to minimize noise. Opt for tension amplifiers with built-in signal filtering and conditioning capabilities. Place amplifiers away from high-power electrical equipment to reduce interference.

5. System Flexibility and Scalability

- Consideration: The ability to adapt to different web materials and processing conditions is crucial for versatile applications. Scalability is important for future expansion.

- Solution: Choose tension amplifiers with adjustable settings to accommodate various web materials. Ensure that the amplifiers can be easily scaled or upgraded to meet increasing production demands or new applications.

6. Training and Expertise

- Consideration: Proper training for personnel is essential to maximize the effectiveness of tension amplifiers and ensure smooth operation.

- Solution: Invest in comprehensive training programs for staff, covering web tension control principles and specific amplifier features. Regularly update training to keep up with technological advancements and best practices.

7. Cost and Budget Considerations

- Consideration: Balancing the initial investment with long-term operational costs is important for financial planning.

- Solution: Perform a cost-benefit analysis to weigh the initial costs of high-quality tension amplifiers against the long-term benefits of improved accuracy, reliability, and reduced downtime. Consider the total cost of ownership, including maintenance and calibration expenses.

Solutions for Successful Integration

1. Comprehensive System Assessment

Before integrating tension amplifiers, perform a detailed assessment of the existing web tension control system. Identify any potential compatibility issues and plan the integration process accordingly. This proactive approach helps avoid disruptions and ensures a smooth transition.

2. Customization and Configuration

Select tension amplifiers that offer customizable settings to match the specific needs of your application. Configurable input ranges, multiple output options, and adjustable parameters allow for precise control and adaptability to various web materials and processing conditions.

3. Robust Design and Durability

Choose tension amplifiers with robust design features suitable for industrial environments. Look for models with rugged enclosures, temperature compensation, and vibration resistance. These features ensure reliable performance even in challenging conditions, minimizing the risk of downtime.

4. Advanced Signal Processing

Opt for tension amplifiers with advanced signal processing capabilities, including filtering and conditioning. These features enhance signal quality, reduce noise, and improve the accuracy of tension measurements, leading to better control and product quality.

5. Regular Training and Updates

Implement ongoing training programs for personnel to keep them informed about the latest developments in web tension control technology and best practices. Regular updates ensure that staff are well-equipped to operate and maintain the tension amplifiers effectively.

6. Long-Term Support and Service

Establish a relationship with the tension amplifier manufacturer or supplier to ensure access to technical support, spare parts, and service. Reliable support helps address any issues promptly, minimizing downtime and maintaining system performance.

Conclusion

Integrating tension amplifiers into web tension control systems offers numerous benefits, including enhanced accuracy, improved stability, and seamless integration with modern control systems. The integration process involves careful consideration of compatibility, calibration, environmental factors, signal quality, flexibility, training, and cost. By addressing these considerations with appropriate solutions, industries can achieve precise and reliable web tension control. Adopting robust, adaptable tension amplifiers and ongoing staff training ensures long-term success and readiness for future advancements in web tension control technology.