How to Handle Challenging Materials in Web Guiding

Table of Contents

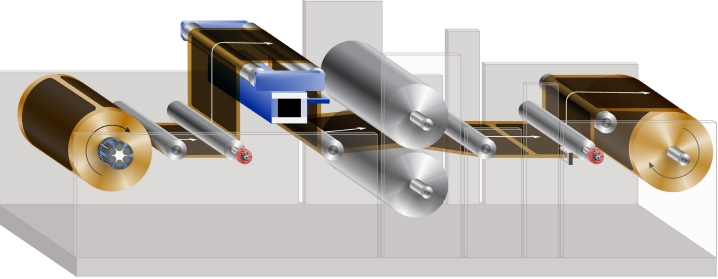

Web guiding systems are essential for maintaining the accurate alignment and positioning of continuous webs of material in industrial processes such as printing, coating, laminating, and converting. However, handling challenging materials such as thin films, nonwovens, and flexible substrates, can pose significant difficulties due to their unique properties. Understanding these challenges and the latest technological solutions can improve efficiency and product quality in web-based production systems.

Common Challenging Materials for Web Guiding

This chart outlines common challenging materials and provides insight into effective web guiding management considerations.

| Material | Challenges | Key Considerations for Handling |

| Thin Films | High elasticity, prone to stretching or tearing | Use precise tension control, non-contact guiding |

| Nonwovens | Variable thickness, potential for deformation | Utilize sensors for edge detection, adjust tension zones |

| Transparent Films | Difficult to detect with standard sensors | Implement ultrasonic or infrared sensors |

| Laminates | Multi-layer composition, thickness variability | Use adaptable tension systems, ensure consistent alignment |

| Recycled Paper | Inconsistent texture and thickness | Deploy load cells for tension consistency, manage web path |

| Coated Materials | Surface sensitivity, risk of damage | Opt for air-cushion guiding, minimize contact points |

| Stretchable Fabrics | High elasticity and edge wandering | Use servo-driven actuators, even tension distribution |

| Synthetic Polymers | Electrostatic build-up, sticking issues | Install anti-static devices, use low-friction rollers |

| Moisture-sensitive Paper | Expansion or contraction with humidity | Maintain environmental controls, adjust tension dynamically |

Technological Solutions for Handling Challenging Materials in Web Guiding

Handling challenging materials in web guide demands innovative technological solutions to maintain efficiency, reduce waste and achieve high-quality output.

1. Advanced Sensor Technologies

- Ultrasonic and Infrared Sensors: Traditional optical sensors may struggle to detect transparent, reflective, or highly variable materials. Ultrasonic sensors use sound waves to detect edges, making them ideal for clear or transparent films. Infrared sensors, on the other hand, are effective for materials with variable opacity.

- Laser Edge Detectors: These sensors offer high precision in detecting edges, particularly useful for thin or high-speed webs. Laser sensors provide accurate feedback for maintaining web position even when handling narrow or fast-moving materials.

Benefits

- Reliable detection of edges in difficult-to-monitor materials.

- Enhanced control in diverse web guiding applications.

2. Precision Tension Control Systems

- Load Cells and Dancer Rolls: Incorporating load cells or dancer rolls into the web guide system helps monitor and control tension accurately. This is essential for materials prone to stretching or deformation, such as nonwovens and elastic films.

- Closed-Loop Tension Control: Real-time adjustments to web tension are made using feedback loops that automatically correct variations, maintaining stability and preventing material damage.

Benefits

- Maintains consistent tension, reducing wrinkling and stretching.

- Enhances web alignment and tracking for thin or elastic materials.

3. Servo-Driven Actuators

- Responsive Positioning: Servo-driven actuators provide high-precision control over guide rollers, allowing for immediate response to sensor data. This technology is particularly beneficial for correcting alignment issues in real time, which is essential for handling webs with variable properties.

- Smart Feedback Systems: Modern servo-driven systems incorporate intelligent feedback that can anticipate and correct alignment deviations proactively.

Benefits

- Quick and precise adjustments improve alignment accuracy.

- Reduces the likelihood of edge wandering or web tears.

4. Non-Contact Web Guiding Solutions

- Air-Cushion Guiding Systems: These systems use jets of air to guide and support the web without direct contact. This is especially useful for handling delicate or surface-sensitive materials that may be damaged by traditional contact-based methods.

- Low-Friction Rollers: Rollers coated with special low-friction materials help minimize drag and reduce the risk of scratching or damaging sensitive webs.

Benefits

- Prevents surface damage, preserving the quality of sensitive materials.

- Reduces friction-related wear and operational resistance.

5. Electrostatic Control Devices

- Ionizers and Anti-Static Bars: To manage the buildup of static electricity, which is common in synthetic and thin materials, anti-static devices neutralize charges, preventing sticking or repelling issues that can disrupt the web path.

- Static Charge Monitoring: Advanced systems measure static levels in real time and activate discharge mechanisms as needed.

Benefits

- Improves web flow consistency.

- Enhances safety and operational stability.

6. Adaptive Control Systems

- AI-Powered Controllers: Artificial intelligence and machine learning algorithms analyze sensor data and historical performance metrics to optimize web guiding systems. These controllers can predict potential alignment issues and adjust settings proactively.

- Integrated Monitoring Software: Software platforms collect data from various sensors and devices, allowing operators to monitor performance and make adjustments remotely.

Benefits

- Increases the overall efficiency of web guiding systems.

- Reduces downtime due to manual adjustments and operator error.

Best Practices for Handling Challenging Materials in Web Guiding

This chart highlights the best practices that can be implemented to address various challenges in web guiding control systems, ensuring optimal performance and material handling.

| Challenge | Best Practices | Explanation |

| Elasticity and Deformation | Use precise tension control systems | Implement closed-loop tension control to avoid stretching or wrinkling. Use load cells and dancer rolls for real-time adjustments. |

| Variable Thickness | Employ adaptive tension systems and precise edge detection | Use tension control systems and sensors that adjust to thickness variations, ensuring uniform guidance. |

| Surface Sensitivity | Utilize non-contact guiding methods such as air-cushion systems | Non-contact systems prevent surface damage by guiding material with air jets or low-friction rollers. |

| Electrostatic Build-Up | Install ionizers or anti-static bars | Anti-static devices help neutralize static charges, ensuring smooth material flow without sticking. |

| Moisture Sensitivity | Maintain controlled environment and adjust tension dynamically | Control humidity levels and adjust tension in real-time to accommodate material expansion or contraction due to moisture. |

| Transparency or Reflectivity | Use ultrasonic or infrared sensors | Specialized sensors can detect edges of transparent or highly reflective materials, improving alignment accuracy. |

| High Friction | Employ low-friction rollers and coatings | Low-friction rollers reduce drag, preventing damage or misalignment due to resistance during processing. |

| Adhesive Layers | Utilize special handling techniques like non-stick rollers | Use rollers or materials coated with non-stick surfaces to handle adhesive layers without causing jams or misfeeds. |

To sum up, handling challenging materials in web guiding requires a combination of advanced technology and best practices. Through adopting cutting-edge sensors, precise tension control, servo-driven actuators, non-contact solutions, etc, manufacturers can overcome the inherent difficulties in web guide associated with flexible, delicate and variable materials. Adopting these strategies not only ensures smoother operation but also improves product quality and operational efficiency.