How to Enhance Precision in Web Tension Control for High-speed Printing and Packaging

Table of Contents

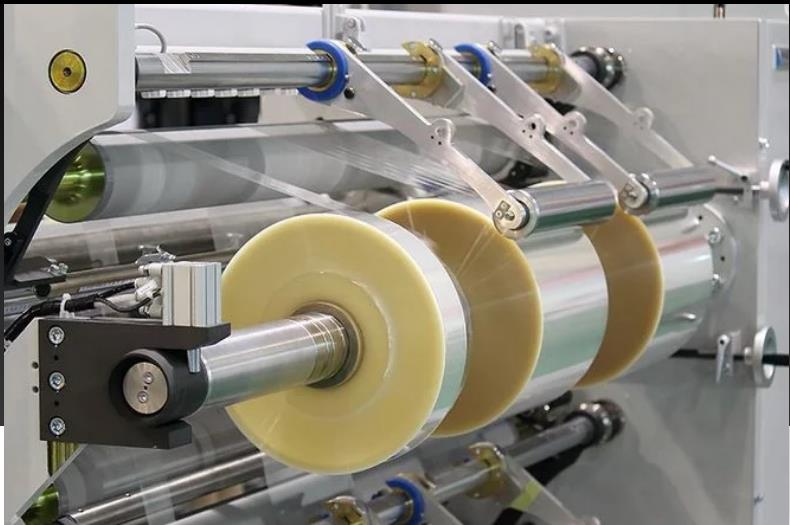

Maintaining optimal web tension is crucial for consistent quality and efficiency in high-speed printing and packaging operations. Poor tension control can lead to defects such as wrinkles, breaks, registration errors, etc, ultimately impacting productivity and profitability. To overcome these challenges, advanced techniques and technologies are essential for ensuring precise web tension control. This article explores the importance of precision in web tension control and the key solutions that enhance it.

The Importance of Web Tension Control in High-speed Printing and Packaging

Web tension refers to the force applied to a web of material as it moves through the printing or packaging machinery. Maintaining uniform tension is critical for the following reasons:

- Print Quality: In high-speed printing, maintaining consistent tension prevents issues such as misalignment, registration errors, or smudging. Proper tension control ensures that the material feeds smoothly through the printing presses, resulting in sharper images and more accurate text. Irregular tension can lead to print inconsistencies that affect the quality and legibility of the final product.

- Product Integrity: In packaging, precise web tension is essential for processes like laminating, cutting, and sealing. Uneven tension can cause misalignment in multi-layered materials, leading to defective packages that compromise the safety or appearance of the product. Precise tension management keeps the material uniformly aligned, ensuring that the final product meets quality standards.

- Reduced Waste: Fluctuations in web tension can lead to issues such as web breaks, wrinkles, or stretch marks. Each of these issues results in wasted material, contributing to higher production costs and environmental waste. Precise tension control helps to minimize these problems by keeping the web stable throughout the production process, reducing the chances of material discard.

- Equipment Longevity: Inconsistent tension places extra strain on rollers, motors, and other mechanical components within the printing and packaging machinery. Over time, this additional stress can accelerate wear and lead to more frequent breakdowns or costly repairs. By maintaining consistent web tension, machinery experiences less undue stress, extending its operational lifespan and reducing maintenance costs.

- Optimizing Production Speed: High-speed printing and packaging lines must operate at rapid rates to meet market demands. Accurate web tension control allows these operations to run at maximum speeds without compromising the quality or structural integrity of the product. Uncontrolled tension variations can force operators to reduce speed or pause production to resolve issues, negatively affecting productivity.

Challenges of Web Tension Control in High-speed Printing and Packaging Operations

This chart outlines the main challenges, the causes and the impact of web tension control have on high-speed printing and packaging operations.

| Challenge | Description | Impact |

| Web Breaks and Downtime | Tension inconsistencies can cause web tears, leading to machine stoppages. | Increased downtime and repair costs. |

| Wrinkling and Misalignment | Variations in tension result in buckled or shifted webs, affecting alignment. | Reduced print quality and packaging accuracy. |

| Varying Substrate Properties | Different materials respond differently to tension, complicating control. | Difficulty in standardizing operations. |

| Speed Fluctuations | High-speed changes can cause sudden shifts in tension that are hard to control. | Disrupts consistent production flow. |

| Mechanical Wear | Prolonged tension fluctuations strain components like rollers and brakes. | Increased maintenance and decreased equipment life. |

| Operator Dependency | Manual adjustments can lead to human error. | Inconsistent tension control and productivity. |

Solutions for Enhancing Precision in Web Tension Control During High-speed Printing and Packaging

To address these challenges, manufacturers and operators can adopt a range of solutions that enhance precision in web tension control.

1. Advanced Tension Control Systems

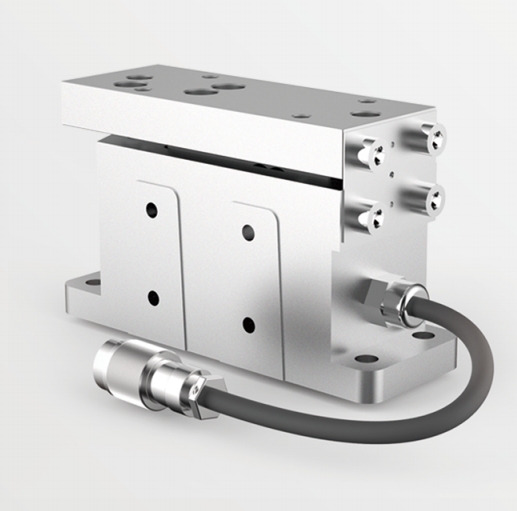

Modern web tension control systems use electronic sensors and automatic adjustments to maintain consistent tension. These systems continuously monitor the tension across different points of the web and make real-time corrections to prevent deviations.

Key Features:

- Load cells or tension sensors provide accurate readings of web force.

- Automatic tension controllers adjust the torque or speed of motors to regulate tension.

2. Dancer Roll Mechanisms

Dancer rolls help absorb slack or maintain constant tension by moving in response to changes in web movement. This system acts as a buffer, maintaining tension stability, especially during acceleration or deceleration.

Benefits:

- Ideal for applications involving frequent speed changes.

- Simple mechanical solution that complements electronic systems.

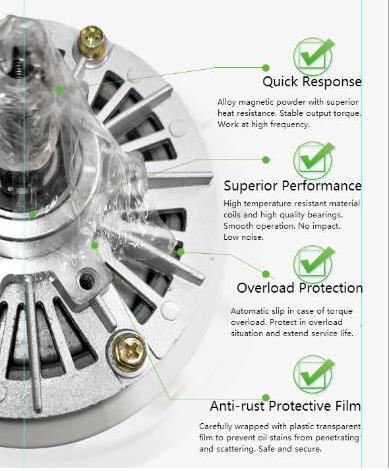

3. Braking and Clutch Systems

Braking and clutch mechanisms can be fine-tuned to adjust the tension on a moving web. Magnetic particle brakes and pneumatic clutches are commonly used due to their ability to provide smooth, variable control.

Advantages:

- Suitable for use in unwinding and rewinding sections of a line.

- Allows for customizable tension based on the type of material processed.

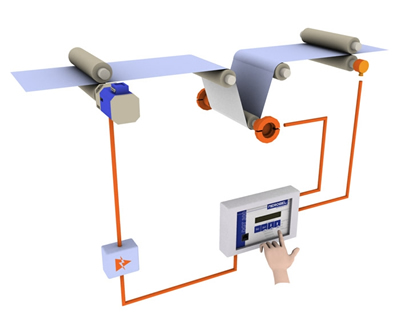

4. Closed-Loop Feedback Systems

A closed-loop feedback system integrates sensors and control software to provide continuous adjustments. This method ensures that tension remains within pre-set limits, minimizing operator intervention and error margins.

How It Works:

- Sensors detect real-time tension values and send data to a central controller.

- The controller processes this data and commands actuators or drives to adjust speed or torque as needed.

5. Adaptive Software Solutions

Software-driven tension control solutions can adapt to different materials and production speeds automatically. These advanced systems use algorithms that learn and adjust based on historical data and production requirements.

Key Features:

- Enhanced predictive control to preempt potential deviations.

- User-friendly interfaces for operators to monitor and adjust settings.

Best Practices for Implementing Precision Web Tension Control in High-speed Printing and Packaging

This chart helps guide high-speed printing and packaging operators in enhancing precision web tension control for improved output quality and process efficiency.

| Best Practice | Description | Benefits |

| Use High-Precision Tension Sensors | Install sensors that provide real-time tension data. | Ensures accurate and consistent tension control. |

| Adopt Closed-Loop Tension Control Systems | Implement automated systems that adjust tension using feedback. | Reduces manual errors and enhances efficiency. |

| Employ Servo-Driven Motors | Utilize servo motors for precise web speed and tension management. | Provides fast, responsive, and reliable control. |

| Integrate Web Guide Equipment and Edge Detectors | Use guides and detectors to prevent misalignment. | Improves web alignment, avoiding defects. |

| Install Dynamic Braking Systems | Implement braking to manage tension during acceleration and deceleration. | Prevents web breaks and maintains stability. |

| Automatic Roll Diameter Compensation | Adjust tension based on changing roll diameters during use. | Maintains consistent tension, reducing material stress. |

| Calibrate for Material Specifics | Calibrate systems to match the properties of different materials. | Enhances performance for various substrates. |

| Regular Maintenance and Upgrades | Keep equipment maintained and incorporate the latest technology. | Ensures optimal operation and long-term reliability. |

To sum up, the demand for high-speed printing and packaging continues to drive the technical advancements in web tension control. Through adopting advanced tension control systems, integrating reliable hardware solutions and leveraging adaptive software, manufacturers can ensure smoother operations and higher product quality, achieving precise web tension control.