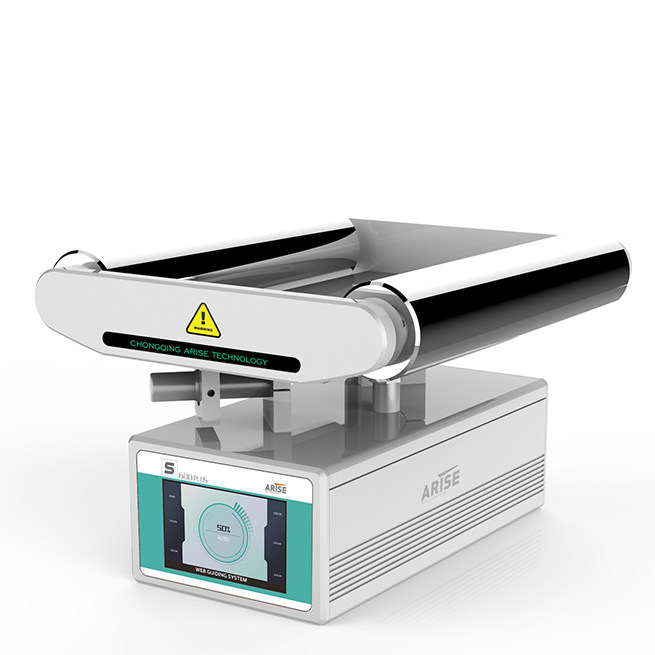

How to Enhance Efficiency with Advanced Web Guiding Technologies In the Manufacturing Industry

Efficiency is a critical aspect in assuring production and profitability in the manufacturing industry. Web directing processes are one area where efficiency is critical. Web guiding technologies allow for precise control and alignment of webs or materials during manufacturing, resulting in optimal quality and reduced waste. The development of advance web guiding technologies has transformed the manufacturing industry. This article investigates how web guiding technologies enhance efficiency in a variety of manufacturing industries.

Precise Control and Alignment Provided by Web Guiding Technologies

Web guiding allows for fine material control and alignment throughout production processes. Traditional manual or mechanical guiding methods frequently fall short in terms of precision and speed. Advanced web directing technologies, such as vision-based systems, edge sensors, and laser guiding, on the other hand, provide great degrees of precision.

Vision-Based Systems

Cameras and image recognition algorithms are used in vision-based web guiding systems to detect and track the web’s edges or specific markers. Even for intricate designs or irregularly shaped materials, this technique enables for precise alignment and correction.

Edge Sensors

Edge guide sensors detect the web’s edges using infrared or ultrasonic technology. These sensors give the guiding system real-time feedback, allowing for precise control and alignment.

Laser Guiding

Laser beams are used in the laser web guiding control system to establish reference lines on the surface. These lines serve as a visual guide for operators, ensuring accurate positioning and alignment.

Reduced Downtime and Waste Provided by Web Guiding Technologies

Advanced web guiding technologies cut downtime and waste in manufacturing processes dramatically. These technologies increase production efficiency by boosting accuracy and reducing errors.

Faster Setup and Changeovers

Web guides with automated calibration and setup capabilities make moving between different materials or product requirements easier. This saves downtime associated with manual changes and guarantees that each production run is set up quickly and accurately.

Continuous Alignment and Correction

Continuous alignment and adjustment throughout manufacturing is possible thanks to real-time data from web guide systems. Any deviations or misalignments are promptly noticed and repaired, reducing the occurrence of waste or damaged items.

Increasing Speed and Productivity

Precise control if web guiding system allows manufacturers to run their production lines at higher speeds without sacrificing quality. As a result, productivity and throughput rise, resulting in a more efficient production process.

Enhancing Quality and Consistency Provided by Web Guiding Technologies

Advanced web guiding technologies improve the overall quality and uniformity of created products. These technologies remove variances and errors caused by human or mechanical guiding methods by assuring exact alignment and control.

Accurate Printing and Coating

Precise web guiding is critical in industries like as printing and coating to provide accurate registration, color constancy, and uniform coverage. Precision control is enabled by advanced web guiding technologies, resulting in high-quality and visually appealing end results.

Reduction in Defects and Rework

Defects or discrepancies in the final product can result from misalignment or inconsistent web guide control. Advanced web guiding methods reduce the requirement for rework or discard materials, thus improving total product quality.

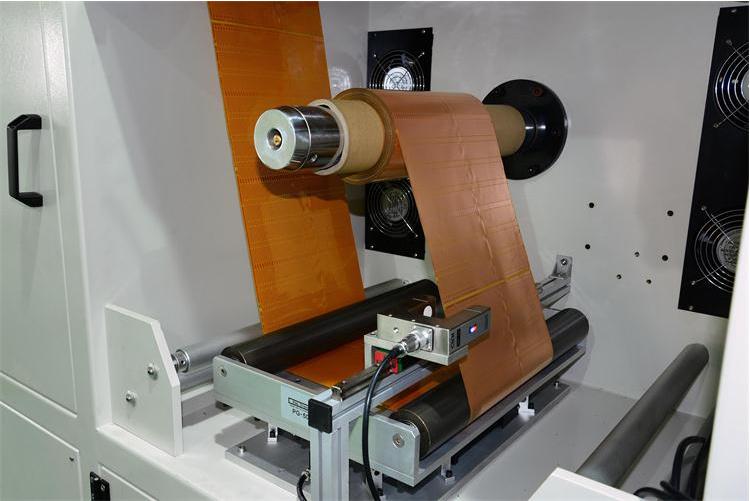

Consistent Material Tension

Maintaining consistent tension in the web throughout the production process is vital for preventing wrinkles, creases, or stretching. Advanced web guiding technologies enable precise tension control, ensuring a smooth and consistent web flow, and minimizing material waste.

Integration of Web Guiding Technologies with Automation and Industry 4.0

Maintaining continuous tension in the web throughout the manufacturing process is critical for avoiding wrinkles, creases, and stretching. Advanced web guiding technologies allow for exact tension management, resulting in a smooth and constant web flow while minimizing material waste.

Integration with Automation

Web guiding technologies can be effortlessly connected with automation systems and Industry 4.0 projects, increasing industrial process efficiency. Other automated systems, such as robotic arms or material handling equipment, can be integrated with the web guide system. This allows for seamless coordination and synchronization, which reduces manual involvement while increasing overall efficiency.

Data Collection and Analysis

Advanced web guiding control technologies collect data on material alignment, tension, and manufacturing parameters in real time. This data may be evaluated to discover trends, optimize operations, and proactively address possible concerns, resulting in continual efficiency and quality improvement.

Predictive Maintenance

Web guide system with predictive maintenance features can monitor performance, detect problems, and proactively plan repair actions. This lowers unanticipated problems, downtime, and maintenance expenses.

Summary

Advanced web guiding technologies provide considerable benefits to manufacturers looking to improve the efficiency of their manufacturing operations. Manufacturers who continue to use web guiding machines should expect increased levels of efficiency, improving product quality, and a competitive advantage in the ever-changing production landscape.