How to Advance Enhanced Material Handling in Web Guide Systems

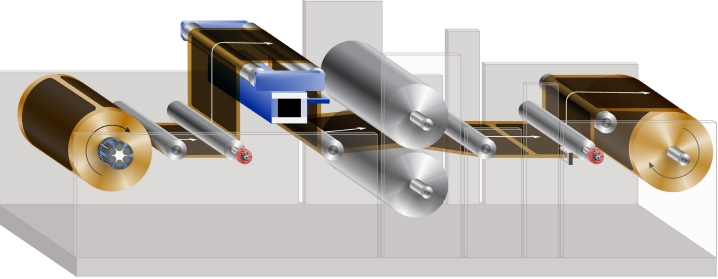

Web guide systems, crucial for maintaining the alignment of materials like paper, film, textiles, and metals as they travel through processing equipment, are at the heart of this quest for perfection. Enhanced material handling in web guide systems represents a significant leap forward, addressing traditional challenges and introducing innovations that optimize production processes. This article explores these advancements and their impact on industrial efficiency and product quality.

Understanding Material Handling in Web Guide Systems

This chart provides a comprehensive overview of material handling in web guide systems.

| Aspect | Description |

| Definition | The guide process of managing and controlling the alignment, tension, and movement of materials (webs) as they travel through various stages of production. |

| Key Components | Sensors, actuators, controllers, rollers, and feedback mechanisms used to maintain proper alignment and tension. |

| Primary Functions | Ensuring consistent material alignment, controlling web tension, adjusting for material properties, and preventing defects. |

| Types of Materials Handled | Paper, film, textiles, metals, plastics, and other continuous materials used in manufacturing and processing industries. |

| Challenges Addressed | Misalignment, material stretch or shrinkage, varying material properties, changes in speed, and environmental factors. |

| Applications | Printing, packaging, converting, textiles, plastics processing, and any industry requiring precise material alignment and handling. |

The Importance of Material Handling in Web Guide Systems

Material handling in web guide systems is essential for ensuring that the material being processed remains correctly aligned, preventing defects, and minimizing waste. Proper handling is crucial for applications in printing, packaging, converting, and various other industries where precision is vital. Enhanced material handling capabilities ensure that web guiding systems can adapt to different materials, speeds, and operational conditions, ultimately leading to more consistent and higher-quality outputs.

Innovations in Material Handling for Web Guide Systems

1. Adaptive Control Systems

Real-Time Adjustment

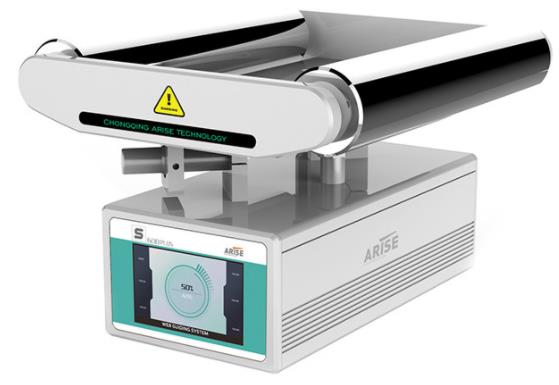

Modern web guide systems integrate adaptive control mechanisms that continuously monitor and adjust material alignment in real-time. These systems utilize feedback from sensors to dynamically adapt to changes in material properties, speed variations, and environmental conditions. By optimizing tension and alignment parameters on the fly, adaptive control systems minimize misalignments and improve overall production quality.

Versatility

Adaptive control systems enable web guide systems to handle a wide range of materials, from thin films to thick substrates, without requiring manual recalibration. This versatility is essential for industries that process diverse materials within the same production line, reducing downtime and setup costs associated with material changeovers.

2. Advanced Sensing Technologies

Laser and Ultrasonic Sensors

State-of-the-art sensors, such as laser and ultrasonic technologies, offer precise edge detection capabilities even for transparent or reflective materials. Laser sensors provide high-resolution measurements, ensuring accurate web positioning, while ultrasonic sensors excel in detecting edges without physical contact, minimizing wear and tear.

Machine Vision Integration

Integration of machine vision systems enhances the capabilities of web guide systems by providing visual feedback and analysis. Machine vision can detect subtle defects or deviations in material alignment that may not be apparent to traditional sensors. This technology is particularly beneficial for high-speed applications where rapid adjustments are necessary to maintain quality and throughput.

3. Material Compatibility and Handling

Broad Range Handling

Enhanced material handling systems can manage a broad spectrum of materials, including delicate films, flexible textiles, and high-strength composites. These systems incorporate adjustable rollers, pneumatic grippers, or adaptive conveyor belts to accommodate different material characteristics and prevent damage during processing.

Surface Sensitivity

Innovations in material handling ensure that web guide systems can handle materials with varying surface textures, finishes, or coatings. Specialized handling mechanisms adjust automatically to maintain consistent contact and alignment, preserving material integrity and minimizing surface defects.

4. Energy Efficiency and Sustainability

Low-Power Electronics

Advancements in low-power electronics and efficient actuators reduce the energy consumption of web guide systems. These components contribute to sustainable manufacturing practices by lowering operational costs and minimizing environmental impact.

Optimized Control Algorithms

Sophisticated control algorithms optimize the use of energy within web guide systems, prioritizing efficient motor operation and minimizing idle power consumption. This optimization extends equipment longevity and enhances overall system reliability.

5. Integration and Scalability

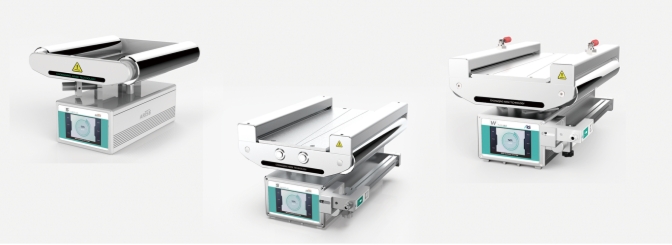

Modular Design

Modern web guide systems feature modular designs that facilitate integration into existing production lines and scalability to accommodate future expansions or modifications. Modular components allow for easy customization based on specific industry requirements or production demands.

Digital Connectivity and IoT Integration

Integration with digital platforms and IoT technologies enables remote monitoring, predictive maintenance, and data-driven insights. Web guide systems equipped with IoT capabilities can autonomously adjust settings based on real-time data, ensuring continuous operation and proactive maintenance scheduling.

Benefits of Enhanced Material Handling in Web Guide Systems

1. Improved Production Quality

- Consistent Alignment: Enhanced material handling ensures consistent material alignment, which is critical for maintaining high production quality. This consistency reduces the likelihood of defects and improves the overall quality of the final product.

- Reduced Waste: By maintaining precise control over material handling, these systems minimize material waste, leading to cost savings and more sustainable operations.

2. Increased Efficiency

- Higher Speeds: Enhanced handling capabilities allow for higher production speeds without compromising alignment or quality. This increase in throughput can significantly boost overall production efficiency.

- Reduced Downtime: With advanced sensing and adaptive control, web guide systems can quickly identify and correct misalignments, reducing downtime and keeping production lines running smoothly.

3. Operational Flexibility

- Multi-Material Processing: The ability to handle a wide range of materials means that a single web guide system can be used for multiple applications, reducing the need for specialized equipment.

- Scalability: Enhanced material handling systems are scalable and can be adjusted to meet the needs of different production volumes and complexities.

4. Cost Savings

Lower Operational Costs: Energy-efficient components and reduced waste contribute to lower operational costs, making enhanced material handling systems a financially sound investment.

Maintenance and Longevity: Improved handling reduces wear and tear on both the material and the equipment, leading to lower maintenance costs and longer system lifespans.

Conclusion

Enhanced material handling in web guide systems represents a significant advancement in industrial manufacturing, offering numerous benefits in terms of quality, efficiency, flexibility, and cost savings. As industries continue to demand higher precision and faster production rates, the innovations in material handling within web guiding system equipment will play a crucial role in meeting these challenges. Through adopting these advanced systems, manufacturers can produce superior products with greater efficiency and lower costs.