How to Address the Challenges of Tension Control in Various Industries

Effective tension control is crucial across a wide range of industries, particularly in sectors dealing with continuous materials such as paper, film, textiles, and metals. However, each industry faces unique challenges in maintaining optimal tension, requiring specific solutions to address them.

Understanding Tension Control

Tension control is the process of regulating the tension applied to materials during production processes to ensure consistent quality and performance.It is essential in industries such as printing, packaging, textiles, metals, and wire manufacturing, where materials like paper, film, fabric, or wire are handled continuously. Proper tension control prevents issues like stretching, tearing, wrinkling, and misalignment, enhancing product quality and reducing waste. Advanced tension control systems use sensors, feedback mechanisms, and automated controls to maintain the desired tension throughout the process, optimizing efficiency and minimizing defects.

The Importance of Tension Control in Various Industries

This chart highlights industries where tension control plays a critical role in ensuring product quality and consistency.

| Industry | Description of Tension Control Applications |

| Printing & Packaging | Ensures consistent tension to avoid wrinkles, misalignments, and defects in printed materials and packaging films. |

| Textile | Maintains fabric tension during weaving, knitting, and dyeing processes for uniform quality. |

| Paper & Pulp | Controls paper tension during winding, cutting, and printing to prevent tearing and wrinkling. |

| Plastic Film Manufacturing | Regulates film tension during extrusion, coating, and slitting to achieve consistent thickness and avoid defects. |

| Metal Processing | Controls tension in metal sheets, wires, and coils during rolling, slitting, and coating processes to ensure product quality. |

| Battery Production | Ensures precise tension in electrode and separator materials during assembly for optimal battery performance. |

| Converting | Manages the tension of materials like paper, foil, and films during converting processes like lamination and die-cutting. |

| Rubber & Tire Manufacturing | Regulates tension in rubber materials during extrusion and assembly for consistent product dimensions. |

| Medical & Pharmaceutical | Ensures accurate tension control in materials like medical films, packaging, and tubing during production. |

Effective Solutions to Address the Challenge of Tension Control in Various Industries

1. Paper and Packaging Industry

Challenges

In the paper and packaging industry, maintaining consistent tension is critical to avoid issues such as web breaks, misalignment, and wrinkles. Varying thicknesses, humidity levels, and material characteristics can all impact tension control during production.

Solutions

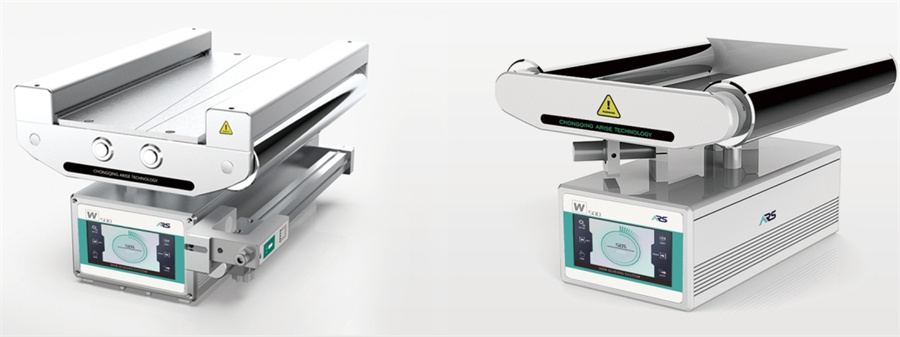

- Automatic Tension Control Systems: Advanced tension control systems equipped with sensors and actuators can automatically adjust the tension in real-time, accommodating changes in material properties and environmental conditions.

- Closed-loop Feedback: Implementing closed-loop feedback mechanisms ensures that tension remains within specified limits, reducing the likelihood of web breakage or material damage.

2. Textile Industry

Challenges

The textile industry faces challenges with delicate fabrics, which can easily stretch or tear if tension is not properly managed. Variations in material elasticity and the use of different fabric types on the same production line further complicate tension control.

Solutions

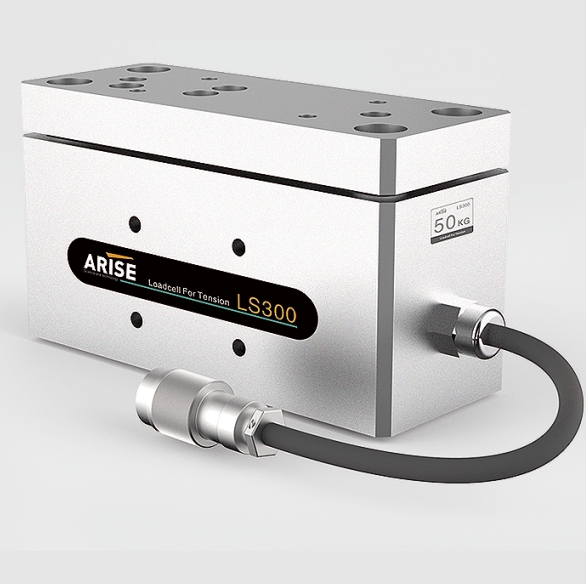

- Load Cells and Dancer Rolls: These tools help monitor and adjust tension levels by compensating for changes in material elasticity. By continuously adjusting tension, they help prevent stretching or tearing of fabrics.

- Tension Zoning: Dividing the production line into zones with specific tension controls for each section allows operators to fine-tune tension for different fabric types.

3. Metal Processing Industry

Challenges

In metal processing, tension control is essential for processes like rolling, stamping, and cutting. Metals, especially thin sheets, are prone to stretching, wrinkling, and misalignment when tension is not properly managed. Additionally, varying metal thicknesses and surface conditions present further challenges.

Solutions

- Tension Brakes and Clutches: By using braking systems to precisely control the feed rate of metal sheets, manufacturers can maintain constant tension throughout the process. This is particularly useful for preventing sheet misalignment or excessive stretching.

- Precision Sensors: Accurate tension sensors can detect even slight variations in tension, allowing operators to make quick adjustments to avoid material defects.

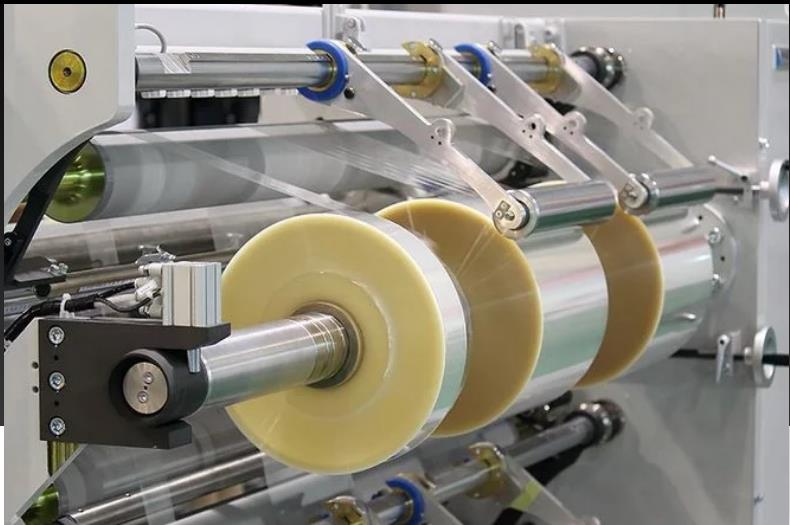

4. Plastic Film and Flexible Packaging Industry

Challenges

Flexible materials such as plastic films are sensitive to stretching, and maintaining uniform tension across the width of the material is essential to avoid defects like wrinkles, bubbles, or uneven thickness. Varying thickness and material properties further complicate tension control.

Solutions

- Web Guide Systems: These web guiding systems help keep the material properly aligned, ensuring consistent tension across the width of the material. This reduces the likelihood of defects such as edge wrinkles and misalignment.

- Differential Drives: These allow independent control of multiple sections of the production line, ensuring precise tension management for each stage of the process, even when dealing with materials of varying thickness.

5. Printing Industry

Challenges

In printing, tension control is critical for preventing misalignment, registration errors, and uneven ink application. High-speed production and varying material types add complexity to maintaining consistent tension throughout the process.

Solutions

- Tension Control Systems with Integrated Monitoring: Modern printing lines often use integrated tension control systems that monitor tension in real-time and adjust accordingly. This prevents issues like paper jams and misregistration.

- Servo-driven Tension Control: Servo motors provide precise control over tension in printing applications, helping to maintain consistent tension even during rapid changes in production speed.

6. Wire and Cable Industry

Challenges

Tension control in wire and cable production ensures that wires do not stretch or break during drawing, coating, or winding processes. The challenge is maintaining consistent tension across long runs of material, particularly when dealing with materials of different diameters or stiffness.

Solutions

- Tension Monitoring Systems: These systems use load cells or tension sensors to continuously monitor and adjust tension levels. They prevent stretching or breakage by dynamically controlling the feed and take-up rates.

- Variable Speed Drives: By using variable speed drives, manufacturers can control the speed of material feed to maintain consistent tension across varying production speeds and material types.

Overall, the challenges of tension control vary significantly across industries, depending on the material properties, production speed and specific processes involved. However, common solutions such as automated tension controller, load cells, braking systems, and closed-loop feedback mechanisms can be applied across different sectors to address these challenges. Tailoring tension control strategies to the specific needs of each industry is essential for overcoming the unique challenges faced during production, ensuring high-quality output and maximizing operational efficiency.