How Image Processing Techniques Applied for Print Quality Inspection

Table of Contents

With the increasing complexity of print jobs and the demand for high precision, traditional manual printing inspection methods are no longer sufficient. Automated print inspection systems, powered by advanced image processing techniques, have become essential for achieving consistent and accurate print quality. This article explores how various image processing techniques are applied in these systems to enhance print quality control.

Understanding Print Quality Inspection

Print quality inspection is vital for detecting defects and ensuring that printed materials meet specified standards. Modern inspection systems use sophisticated image processing techniques to automate this process, providing real-time feedback and reducing the likelihood of human error. By leveraging high-resolution cameras and advanced algorithms, these systems can identify a range of issues, from color inconsistencies to alignment problems.

What are the Key Factors Affecting Print Quality Inspection

This chart highlights the key factors that influence the effectiveness and accuracy of print quality inspection systems.

| Factor | Description | Impact on Print Quality Inspection |

| Image Resolution | The level of detail captured in the inspection images. | Higher resolution allows for the detection of finer defects; lower resolution may miss small issues. |

| Lighting Conditions | The quality and consistency of lighting used during image capture. | Proper lighting minimizes shadows and reflections, ensuring accurate defect detection. |

| Camera Calibration | The precision of camera settings such as focus, exposure, and positioning. | Accurate calibration ensures clear, undistorted images, improving defect detection reliability. |

| Defect Detection Algorithms | The algorithms used to identify and classify defects. | Advanced algorithms improve defect identification accuracy, while basic algorithms may miss subtle issues. |

| Edge Detection Accuracy | The precision of edge detection in the inspection process. | Accurate edge detection is crucial for identifying issues like misalignment and blurring. |

| Color Consistency Metrics | Methods for measuring and comparing color accuracy against standards. | Ensures uniform color reproduction; inconsistencies can indicate issues with ink density or color mixing. |

| Thresholding and Segmentation | Techniques for isolating defects in specific regions of the image. | Helps in detecting localized defects; improper thresholding can lead to missed or false defect detections. |

| Texture Analysis Methods | Techniques for examining surface texture and patterns in the print. | Detects subtle surface defects such as streaks or uneven ink distribution. |

| Pattern Matching Accuracy | The system’s ability to compare printed patterns or logos with predefined templates. | Ensures accurate reproduction and alignment of patterns; poor matching can lead to misalignment or missing elements. |

| Optical Character Recognition (OCR) | The accuracy of text recognition and comparison with expected content. | Verifies text accuracy and legibility; errors in OCR can result in missed text defects or incorrect content. |

| Environmental Noise | Factors like dust, reflections, or vibrations that affect image capture. | Minimizing noise ensures clearer images; environmental interference can distort images and affect defect detection. |

| Speed of Assessment | The rate at which the system processes and evaluates images. | Faster systems improve production efficiency but may risk overlooking subtle defects if not properly calibrated. |

| System Training and Learning | The ability of machine learning models to adapt and improve over time. | Well-trained systems enhance defect detection and classification accuracy, while poorly trained systems may miss defects. |

Key Image Processing Techniques Used in Print Quality Inspection

1. Edge Detection

Edge detection techniques identify the boundaries and contours of printed elements, such as text and graphics, by detecting changes in pixel intensity.

Algorithms: Common algorithms include Sobel, Canny, and Prewitt operators.

Applications: Detects issues such as blurring, misalignment, and sharpness of edges, ensuring that printed elements are clear and well-defined.

2. Color Consistency Analysis

Color consistency analysis ensures that the colors in printed materials match the intended design by comparing printed colors to reference standards.

- Methods: Techniques include color histogram comparison and color space transformations (e.g., HSV, Lab).

- Applications: Detects color deviations and ensures uniform color reproduction across prints, crucial for branding and packaging.

3. Texture Analysis

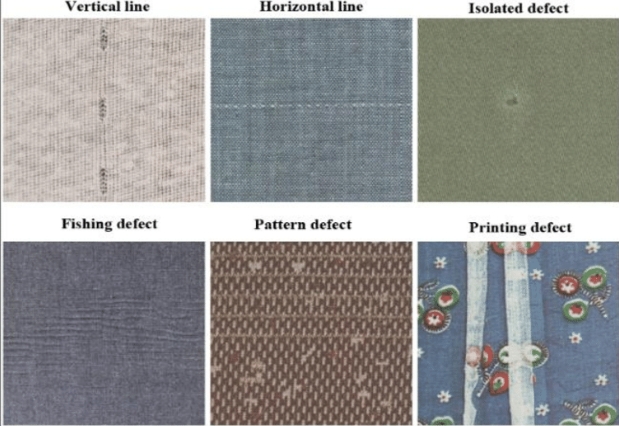

Texture analysis examines the surface texture of printed materials to identify defects such as streaks, banding, or uneven ink distribution.

- Techniques: Methods like Gray Level Co-occurrence Matrix (GLCM) and wavelet transforms are used.

- Applications: Identifies subtle surface irregularities that may affect print quality, ensuring a smooth and even finish.

4. Defect Detection Using Thresholding and Segmentation

Thresholding and segmentation techniques are used to isolate and identify specific defects in printed materials.

- Techniques: Thresholding converts grayscale images into binary images, while segmentation divides images into regions for detailed analysis.

- Applications: Detects defects such as spots, missing prints, or ink blotches, allowing for precise defect localization and correction.

5. Pattern Matching and Registration

Pattern matching and registration techniques verify the accurate reproduction and alignment of specific patterns, such as logos and barcodes.

- Techniques: Template matching and Fourier transforms are commonly used.

- Applications: Ensures that printed patterns are correctly aligned and accurately reproduced, preventing issues like misalignment or missing elements.

6. Optical Character Recognition (OCR)

Optical Character Recognition (OCR) is used to verify the accuracy and legibility of printed text.

- Techniques: OCR algorithms extract and analyze text from images, comparing it to expected content.

- Applications: Ensures that printed text is correct, legible, and free from errors such as missing characters or incorrect fonts.

7. Machine Learning for Defect Classification

Machine learning techniques enhance defect detection by allowing systems to learn and adapt to new types of defects.

- Techniques: Convolutional Neural Networks (CNNs) and other deep learning models are employed.

- Applications: Improves defect detection and classification accuracy, reducing false positives and adapting to new defect types over time.

8. Real-Time Monitoring and Feedback

Real-time monitoring and feedback mechanisms enable continuous inspection during the printing process.

- Techniques: High-resolution cameras capture images, and real-time analysis provides immediate feedback.

- Applications: Allows for immediate defect correction and minimizes waste by detecting issues as they occur.

Challenges and Future Trends in Image Processing Techniques for Print Quality Inspection

This chart provides a concise overview of the key challenges and future trends in image processing techniques for print quality inspection, highlighting areas for improvement and anticipated advancements.

| Category | Challenges | Future Trends |

| Defect Detection | 1. Difficulty in detecting and classifying complex or subtle defects. | 1. Advanced machine learning algorithms and AI for more accurate and adaptable defect detection. |

| Image Resolution | 2. Limitations in resolution affecting the ability to detect fine defects. | 2. Increased use of high-resolution and multi-spectral imaging to capture more detailed defect information. |

| Color Consistency | 3. Challenges in maintaining and analyzing color accuracy under varying conditions. | 3. Implementation of advanced color measurement and calibration techniques, including hyperspectral imaging. |

| Lighting Conditions | 4. Variability in lighting affecting image quality and defect detection. | 4. Development of advanced lighting systems and adaptive algorithms to ensure consistent illumination. |

| Processing Speed | 5. Slow processing speeds impacting real-time defect detection. | 5. Enhanced computational efficiency through optimized algorithms and hardware acceleration. |

| Data Management | 6. Handling and analyzing large volumes of image data efficiently. | 6. Utilization of cloud-based solutions for scalable data management and real-time analytics. |

| Integration with Systems | 7. Difficulty integrating image processing systems with existing production workflows. | 7. Improved integration with Industry 4.0 technologies for seamless operation and data sharing. |

| Adaptability | 8. Need for systems to adapt to different types of print jobs and materials. | 8. Increased flexibility and customization in image processing techniques for diverse applications. |

| User Interaction | 9. Limited advanced user interfaces for interacting with inspection systems. | 9. Development of intuitive user interfaces and visualization tools for better operator interaction. |

| Machine Learning Models | 10. Challenges in training and updating machine learning models to handle new defect types. | 10. Deployment of more sophisticated AI models with continuous learning capabilities to improve accuracy. |

To sum up, advanced image processing techniques play a crucial role in modern print quality inspection systems, providing accurate, real-time analysis of printed materials. Through adopting methods such as edge detection, color consistency analysis, texture analysis, and machine learning, these systems ensure high standards of print quality and operational efficiency.