How High-resolution Cameras are Used for Precision Print Inspection Systems

Table of Contents

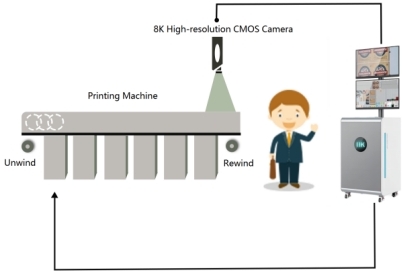

The demand for flawless print quality across industries such as packaging, publishing, and labeling has never been greater. Precision print inspection systems powered by high-resolution cameras ensure the quality and consistency of the printed products. These inspection systems offer an unparalleled combination of speed, accuracy, and adaptability, making them indispensable in modern printing operations.

Understanding the Role of High-resolution Cameras in Print Inspection

Common challenges faced by printing inspection systems include:

- Color misregistration.

- Text and pattern inconsistencies.

- Surface defects like smudges, streaks, or scratches.

High-resolution cameras are at the core of advanced inspection systems for printing quality. They address the these challenges by capturing intricate details ensures that even the most subtle defects are detected. These cameras bridge the gap between manual quality checks and automated inspection systems, delivering precise and reliable results at production speeds.

Key Features of High-resolution Cameras for Print Inspection Systems

1. High Pixel Density

- Description: High-resolution cameras capture ultra-detailed images with pixel densities ranging from 12 MP to over 50 MP.

- Benefits: Enables the detection of tiny defects, such as color inconsistencies, text misalignment, and surface blemishes, ensuring precision.

2. High-Speed Frame Rates

- Description: Supports real-time imaging even in high-speed production environments, with frame rates reaching up to several hundred frames per second.

- Benefits: Ensures continuous inspection without slowing down production lines, maintaining operational efficiency.

3. Wide Dynamic Range (WDR)

- Description: Cameras equipped with WDR technology can capture high-quality images in varying lighting conditions.

- Benefits: Suitable for inspecting reflective, transparent, or textured materials without distortion.

4. Adaptive Lighting Integration

- Description: Incorporates adjustable lighting systems such as LED rings or diffuse lighting to illuminate the inspection area.

- Benefits: Enhances visibility of fine details and reduces shadows or glare, improving inspection accuracy.

5. Wide Field of View (FOV)

- Description: High-resolution cameras cover large inspection areas without sacrificing detail.

- Benefits: Reduces the number of cameras required for complete coverage, lowering system complexity and cost.

6. Advanced Image Processing Capabilities

- Description: Built-in image processing algorithms enable edge detection, defect classification, and pattern recognition.

- Benefits: Enhances inspection accuracy and automates defect identification, speeding up decision-making.

7. Seamless Integration with Machine Vision Systems

- Description: Compatible with machine vision software and industrial automation systems.

- Benefits: Facilitates real-time defect analysis and integrates easily into existing workflows.

Applications of High-resolution Cameras in Precision Print Inspection Systems

This chart demonstrates the diverse roles of high-resolution cameras used in 100% inspection system for maintaining quality and reliability across various printing applications.

| Application | Purpose | Impact | Industries |

| Color Consistency Monitoring | Detects color variations and mismatched hues in prints. | Ensures uniform color quality, adhering to brand standards. | Packaging, Advertising, Labels |

| Registration Accuracy Verification | Verifies proper alignment of multi-layer prints. | Prevents image blurring and misalignment issues. | Offset, Gravure, Flexographic Printing |

| Surface Defect Detection | Identifies defects like scratches, smudges, or streaks on printed surfaces. | Delivers defect-free, visually appealing products. | Brochures, Books, Premium Packaging |

| Barcode and QR Code Verification | Ensures readability and alignment of barcodes and QR codes. | Enhances traceability and prevents errors in automated systems. | Retail, Logistics, Pharmaceuticals |

| Text and Graphic Clarity Assurance | Checks clarity and sharpness of fine text and intricate graphics. | Ensures legibility and aesthetic quality of printed designs. | Legal Documents, Marketing Materials, Packaging |

| Print-to-Template Comparison | Compares the printed material against a predefined template for accuracy. | Detects counterfeit or defective items in critical printing. | Security Printing, Passports, Certificates |

| Real-Time Process Monitoring | Continuously inspects during high-speed production runs. | Reduces downtime and minimizes waste with instant corrections. | Industrial High-Speed Printing |

| Inspection of Transparent Materials | Evaluates printing on glossy, transparent, or reflective materials. | Ensures precision on challenging surfaces like films and laminates. | Specialty Packaging, Labels |

| Variable Data Inspection | Checks for accuracy in dynamic data such as serial numbers, batch codes, or personalized content. | Maintains compliance and ensures data integrity. | Food, Pharmaceuticals, Consumer Goods |

| Verification of Security Features | Examines security elements such as holograms, microtext, and watermarks. | Prevents counterfeiting and ensures document authenticity. | Currency Printing, Anti-Counterfeit Materials |

Future Trends in High-resolution Cameras for Print Inspection Systems

- Increased Resolution Capabilities: Future cameras for print inspection will likely achieve resolutions exceeding 100 megapixels. This enhancement will allow even finer detection of defects, ensuring unparalleled quality control in high-precision industries.

- AI-Powered Defect Detection: High-resolution cameras will integrate advanced artificial intelligence (AI) algorithms. These systems can detect complex patterns of defects in real time, reduce false positives, and adapt to evolving quality standards.

- Enhanced Frame Rates for High-Speed Printing: The demand for cameras with higher frame rates will grow, enabling them to keep up with high-speed printing systems. Cameras with faster processing capabilities will provide continuous, lag-free inspection of high-volume prints.

- Multispectral Imaging Capabilities: Incorporating multispectral and hyperspectral imaging into high-resolution cameras will enable the detection of defects invisible to the naked eye, such as subtle color inconsistencies, substrate damage, or chemical residues.

- Compact and Lightweight Designs: Advancements in sensor and lens technology will allow for more compact and lightweight designs, enabling easier integration into existing print inspection systems and reducing mechanical complexity.

- Real-Time Data Analytics: High-resolution cameras will increasingly feature built-in processing units capable of real-time analytics, eliminating the need for external data processing units and enhancing system efficiency.

- Integration with Industry 4.0: The seamless integration of high-resolution cameras with Industry 4.0 systems will enable predictive maintenance, remote monitoring, and automated process adjustments, improving operational efficiency and reducing downtime.

- Improved Low-Light Performance: Enhanced low-light performance will ensure accurate inspection in dimly lit environments, expanding the versatility of print inspection systems.

- Customizable Configurations: Manufacturers will offer more customizable configurations for high-resolution cameras, allowing them to be tailored to the specific needs in inspection system for different print materials and processes.

- Sustainability Focus: Future designs will incorporate energy-efficient components, minimizing power consumption while maintaining performance, contributing to the sustainability goals of the printing industry.

In summary, high-resolution cameras provide offering unmatched precision and efficiency for the print inspection. These print inspection systems equipped with high-resolution cameras not only streamline quality assurance but also enhance the overall productivity of printing operations. With continuous advancements in imaging technology and software integration, high-resolution cameras will remain pivotal in ensuring flawless print quality, helping businesses achieve their quality objectives and gain a competitive edge.