How Edge Position Control Enhances Web Guiding Performance

In industries where continuous material processing is essential, maintaining precise web alignment is crucial for ensuring product quality and operational efficiency. Edge position control can automatically detect and correcting deviations in the lateral position of materials such as paper, film, textiles, and metal sheets, optimizing web guiding performance. Through implementing web edge guide system, manufacturers can significantly improve accuracy, reduce material waste, and enhance overall production efficiency.

Table of Contents

The Role of Edge Position Control in Web Guiding

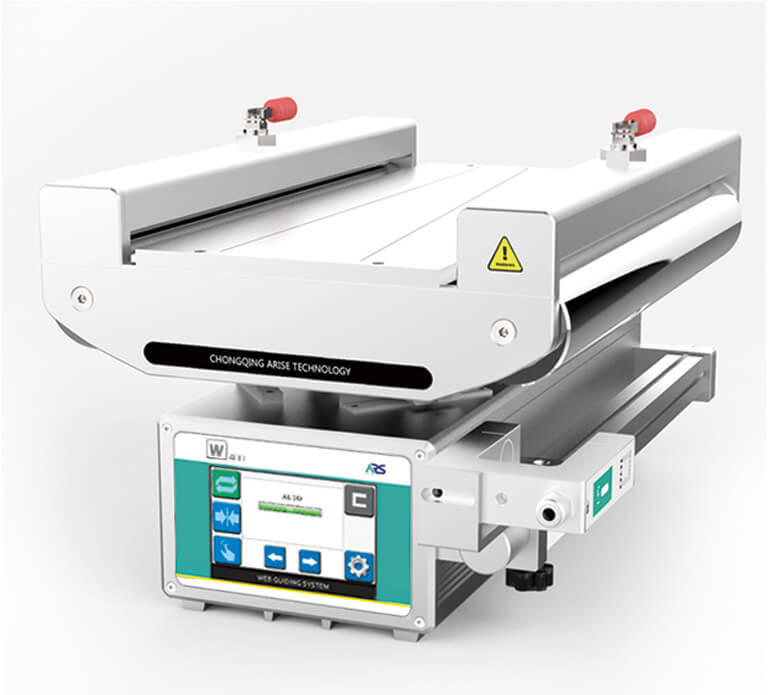

Edge position control is an advanced web guiding technology that ensures materials stay aligned throughout processing. This system consists of three main components: sensors, controllers, and actuators. Sensors continuously monitor the edge position of the web, providing real-time data to the controller. The controller processes this information and sends corrective signals to actuators, which then adjust the web’s position to maintain alignment.

By automating these adjustments, edge position control eliminates manual intervention and reduces the risk of misalignment, which can cause defects such as wrinkles, edge curling, and inaccurate cutting. Whether used in printing, packaging, or textiles, edge position control ensures that the web remains in its designated path, preventing costly errors and rework.

Key Benefits of Edge Position Control in Web Guiding

- Improved Accuracy and Consistency

Edge position control ensures precise lateral positioning of the web, minimizing alignment deviations that can lead to defects. This is particularly critical in industries such as printing and packaging, where even minor misalignments can cause color registration errors or improper sealing. By maintaining consistent web positioning, EPC system enhances overall process accuracy and reliability.

- Reduced Material Waste

Misalignment often results in defective products that need to be discarded or reworked, leading to increased material waste. Edge position control helps manufacturers minimize these losses by preventing edge deviation issues such as wrinkling, curling, and improper cutting. This leads to more efficient resource utilization and lower production costs.

- Enhanced Product Quality

In industries where precision is essential, such as flexible packaging and metal processing, maintaining consistent web alignment ensures high-quality output. Edge position control eliminates defects caused by web instability, leading to uniformity in final products and higher customer satisfaction.

- Increased Production Efficiency

Traditional web guide systems often require manual adjustments, leading to downtime and slower production rates. EPC system automates the correction process, eliminating the need for constant operator intervention. This results in higher production speeds, fewer interruptions, and improved overall efficiency.

- Extended Equipment Lifespan

Misalignment can cause excessive strain on guiding rollers, tension control mechanisms, and other machine components. Over time, this leads to premature wear and potential equipment failures. Edge position control reduces mechanical stress by keeping the web properly aligned, helping extend the lifespan of machinery and reducing maintenance costs.

- Seamless Integration with Automation Systems

Edge guide systems can be integrated into smart manufacturing and Industrial IoT (IIoT) environments, allowing for remote monitoring and real-time adjustments. Digital controllers and AI-driven automation enhance response times and enable predictive maintenance, further improving system reliability and reducing unexpected downtime.

Advanced Technologies in Edge Position Control for Enhancing Web Guiding Performance

1. High-Precision Sensor Technology

Web guide sensors play a pivotal role in edge position control system by detecting the web’s position and feeding real-time data to control systems. Recent advancements have led to more accurate and adaptive sensors that enhance web guiding performance.

- Optical Sensors: These sensors use infrared or laser-based technology to detect the web’s edge with high precision, even in high-speed production environments. They are ideal for applications where fine alignment is critical, such as flexographic printing and electronic film processing.

- Ultrasonic Sensors: Designed for transparent or reflective materials, ultrasonic edge guiding sensors detect the web’s edge by measuring sound wave reflections. These sensors are widely used in plastic film and foil production, where optical sensors may struggle.

- Capacitive and Inductive Sensors: For specialized materials like metal foils and conductive films, capacitive and inductive sensors provide non-contact edge detection, improving reliability in challenging conditions.

2. AI-driven Digital Control Systems

Advanced edge guiding systems incorporate AI-powered digital web guide controllers that process sensor data with greater speed and accuracy. These controllers offer several advantages:

- Real-Time Adaptive Control: AI-based algorithms analyze deviations instantly and adjust actuators more efficiently than traditional systems, reducing alignment errors.

- Predictive Maintenance: AI detects early signs of mechanical wear or sensor drift, allowing for preventive maintenance and reducing unexpected downtime.

- Self-Learning Capabilities: Advanced controllers can learn from past alignment corrections, optimizing future adjustments based on operating conditions.

3. Smart Actuation Mechanisms for Faster Corrections

Actuators are responsible for physically adjusting the web’s position based on sensor input. Innovations in actuator technology have made edge position control systems more responsive and precise.

- Electromechanical Actuators: Faster and more energy-efficient than traditional hydraulic or pneumatic actuators, electromechanical actuators allow for precise and high-speed corrections with minimal lag.

- Servo-Driven Systems: Servo motors provide greater accuracy and dynamic response, making them ideal for high-speed web guiding applications.

- AI-Assisted Actuation: Some advanced EPC systems use AI to predict alignment deviations before they occur, adjusting the web proactively rather than reactively.

4. Integration with Industrial IoT and Smart Manufacturing

The Industrial Internet of Things (IIoT) is transforming edge position control by enabling real-time monitoring, remote diagnostics, and cloud-based data analysis. Key advancements include:

- Remote Monitoring & Control: Web guide systems can now be accessed and adjusted remotely via cloud-based dashboards, reducing the need for on-site intervention.

- Big Data Analytics: By collecting and analyzing alignment data over time, EPC systems can identify trends, optimize performance, and prevent misalignment issues before they become critical.

- Automated Quality Control: Edge position control data can be integrated with automated inspection systems, ensuring that web alignment meets predefined quality standards without manual inspection.

5. AI-Based Edge Detection for Complex Materials

Handling irregular, porous, or multi-layered materials has historically been a challenge for EPC systems. AI-based edge detection algorithms now enable real-time compensation for irregular web edges by recognizing and differentiating between material variations. This advancement is particularly useful in industries like medical packaging, specialty textiles, and thin-film electronics.

6. Adaptive Web Tension and Alignment Synchronization

Edge guide systems now integrate web tension control with edge position correction, providing a more comprehensive web guiding solution. These systems:

- Automatically adjust tension levels based on material type and process conditions.

- Coordinate web alignment with tension variations to prevent defects such as wrinkling or stretching.

- Use AI algorithms to synchronize multiple web guiding stations in complex production lines, ensuring seamless material flow.

Applications of Edge Position Control to Enhance Web Guiding Performance

This chart highlights how edge position control technology optimizes web guiding performance across different industries.

| Industry | Application | Key Benefits |

| Printing | Ensures precise alignment for color registration in flexographic, gravure, and digital printing. | Prevents misprints, improves image sharpness, reduces material waste. |

| Packaging | Maintains accurate web position during cutting, sealing, and laminating processes. | Enhances package quality, minimizes defects, reduces rework. |

| Textiles | Guides fabric during weaving, dyeing, and finishing operations. | Prevents distortion, ensures uniform patterns, reduces fabric waste. |

| Metal Processing | Aligns thin metal sheets and foils in rolling, slitting, and stamping operations. | Ensures precise cuts, improves product uniformity, reduces scrap. |

| Plastic Film & Foil | Controls edge alignment during extrusion, coating, and lamination. | Prevents wrinkles and stretching, enhances film quality, improves efficiency. |

| Electronics Manufacturing | Aligns flexible PCBs, films, and thin-layer materials in circuit production. | Ensures high-precision alignment, reduces defects, improves production speed. |

| Medical & Pharmaceutical | Guides packaging films and medical-grade materials for sterile packaging. | Maintains seal integrity, ensures compliance with industry standards, reduces contamination risk. |

| Battery & Energy Storage | Controls electrode and separator alignment in battery manufacturing. | Prevents misalignment, enhances energy storage efficiency, improves yield. |

Summary

Through integrating advanced sensors, digital controllers, and automation capabilities, edge position control provide real-time corrections that keep materials aligned throughout the production process. As industries continue to adopt smart manufacturing solutions, EPC systems will be increasingly important in optimizing web guiding systems and ensuring superior product quality.