How Does Magnetic Powder Brake Work

Magnetic powder brakes are complex and adaptable devices that are widely utilized in industrial applications that demand accurate and smooth torque control. They are widely utilised in a variety of sectors, including printing, packaging, web tension control, and automotive. In this article, we will look into the essential concepts, components, advantages, and so on of magnetic powder brakes.

Fundamental Working Principle Of Magnetic Powder Brake

A magnetic powder brake functions on the magnetorheology principle, which is the phenomenon in which the rheological properties of a material change in reaction to an applied magnetic field. The magnetic powder, which is a tiny particulate substance with magnetorheological behavior, is the most important component of a magnetic powder brake. Magnetic powder is often made up of microscopic magnetic particles spread in a non-magnetic carrier material, such as oil or grease.

A basic magnetic powder brake is made up of two major parts: a rotor and a stator. The rotor is connected to the input shaft and is powered by the motor or another source of energy, whilst the stator is connected to the output load. Between the rotor and the stator lies a layer of magnetic powder. When the brake is applied, the rotor and stator are brought into close proximity, and the magnetic powder is subjected to a magnetic field.

A coil or electromagnet installed on the stator generates the magnetic field. When an electric current flows through the coil, it creates a magnetic field that pervades the magnetic powder. Because the magnetic particles in the powder align with the magnetic field, the powder solidifies and transmits torque between the rotor and stator. This enables smooth and precise braking torque control.

The magnetic powder brake’s torque level can be adjusted by altering the current provided to the coil. The rheological properties of the magnetic powder can be modified by adjusting the strength of the magnetic field, resulting in variable levels of torque transmission. Magnetic powder brakes are appropriate for applications that demand accurate and smooth torque control because they allow for exact control of the braking torque.

Components of Magnetic Powder Brake

Rotor

The rotor is the brake’s input component, and it is coupled to the motor or power source. When the brake is engaged, it is commonly a cylindrical or disc-shaped component that rotates.

Stator

The stator is the brake’s output component and is connected to the load. It is usually stationary and contains the coil or electromagnet that produces the magnetic field.

Magnetic Powder

The magnetic powder serves as the medium for torque transmission between the rotor and stator. It is made up of small magnetic particles that are spread in a non-magnetic carrier material like oil or grease.

Coil or Electromagnet

The coil, also known as an electromagnet, is in charge of producing the magnetic field that solidifies the magnetic material and transmits torque. It is usually installed on the stator and is powered by an external source.

Advantages Of Magnetic Powder Brake

Smooth and precise torque control

Magnetic powder brakes provide accurate and consistent braking performance by providing smooth and precise torque control. By altering the current provided to the coil, the braking torque may be easily regulated, enabling fine-grained control over the braking process. Precision speed and tension control is possible in applications such as printing, packaging, and web tension management.

High accuracy and repeatability

Magnetic particle powder brakes have great torque control accuracy and repeatability, making them ideal for applications that demand precise and consistent braking performance. This is especially significant in applications where the final product’s quality is dependent on consistent tension management, such as printing, laminating, and coating operations.

Wide torque range

Depending on the size and design of the brake, magnetic powder brakes can function throughout a wide range of torque values, ranging from extremely low to very high torque levels. Because of their torque capacity versatility, they are suited for a wide range of applications, from small-scale to heavy-duty industrial processes.

Fast response time

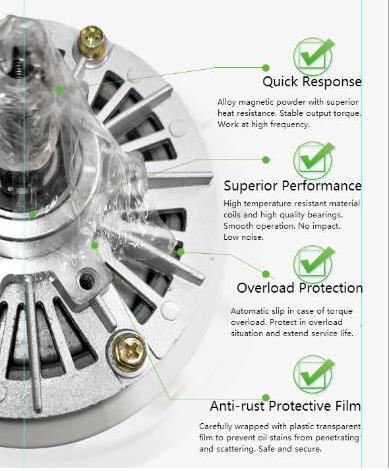

Magnetic powder clutch brakes offer a quick response time, allowing for instantaneous braking torque engagement and disengagement. As a result, they are suited for applications requiring quick torque changes, such as high-speed printing or packaging processes.

Non-contact operation

Powder brakes operate without direct contact between the rotor and stator, hence eliminating wear and friction. As a result, they have a longer service life, less maintenance requirements, and less downtime, making them more cost-effective in the long term.

Overload protection

Magnetic powder brakes can safeguard the driven equipment from overburden. When the torque exceeds the specified limit, the magnetic powder brake slips, preventing equipment damage and ensuring safety.

Noiseless operation

Magnetic powder brakes work silently, producing no noise or vibrations, making them ideal for applications requiring quiet operation, such as printing or packaging.

Compact and lightweight design

Magnetic powder clutch brakes feature a compact and lightweight design that allows them to be easily integrated into a variety of machine systems without adding unnecessary weight or space.

Customizable and adaptable

The tailored Magnetic powder brakes can be applied to specific application needs, such as torque capability, response time, and mounting options. As a result, they are a versatile option for a variety of industrial applications.

Summary

Magnetic powder brakes are a reliable and efficient option in wide applications, for accurate and controlled braking.