How Do Precision Improvements in Web Guide Systems Enhance Manufacturing Processes

Precision and accuracy in web guiding systems are paramount to maintaining product quality, reducing waste, and optimizing production efficiency. Recent advancements in technology have significantly enhanced the precision and accuracy of web guide systems. This article explores the key improvements and their implications for the industry.

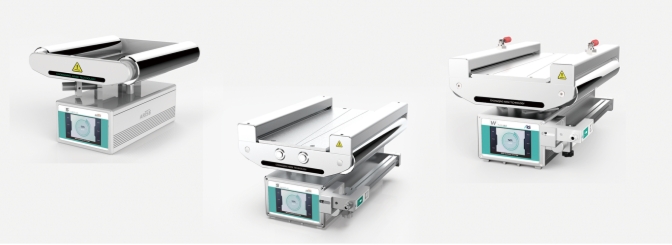

Understanding Web Guide Systems

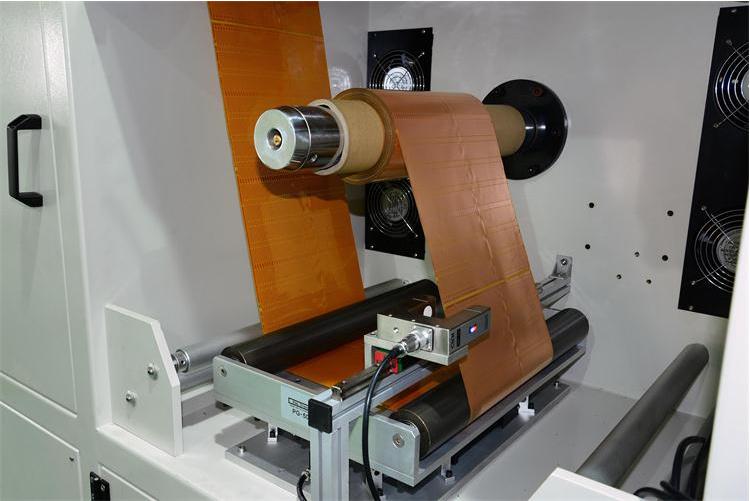

For industrial manufacturing, a web guide system plays a crucial role in ensuring the proper alignment and handling of materials such as paper, plastic films, textiles, and metals. The system is designed to keep a moving web of material properly aligned during the manufacturing process. Web guide control systems use sensors and actuators to detect and correct any lateral deviations of the web from its intended path. The primary goal is to maintain the web’s position within a predefined tolerance to ensure consistent product quality and minimize material waste.

Key Components and Technologies Contributing to the Enhanced Precision of Modern Web Guide Systems

1. Advanced Sensor Technologies

High-precision web guide sensors are at the heart of the guiding systems, providing accurate detection of the web’s position. The following advancements in sensor technology have been pivotal:

- Optical Sensors: These sensors use light to detect the position of the web. Recent improvements in imaging capabilities allow optical sensors to identify minute deviations in web alignment with high resolution. They are less affected by environmental factors such as dust and temperature variations, ensuring consistent performance.

- Infrared Sensors: Infrared sensors detect the web’s position by measuring the infrared light reflected from the web surface. These sensors offer high accuracy and are particularly useful in environments where optical sensors might be compromised.

- Ultrasonic Sensors: Using sound waves to detect the web position, ultrasonic edge sensors can accurately measure the distance between the sensor and the web. They are highly effective in detecting transparent or semi-transparent materials where optical sensors might struggle.

2. Enhanced Actuation Mechanisms

Web guide actuators adjust the web’s position based on sensor data. Recent advancements in actuation technology have improved the speed and precision of these adjustments:

- High-Speed, High-Torque Motors: The development of these motors has significantly enhanced the responsiveness of web guide systems. They enable rapid and precise adjustments to the web’s position, reducing the time required to correct deviations and improving overall system accuracy.

- Piezoelectric Actuators: These actuators offer fine control over small displacements, making them ideal for applications requiring high precision. Piezoelectric actuators can provide extremely accurate positioning, further enhancing the precision of web guide systems.

3. Intelligent Control Systems

Control systems process sensor data and manage the actuators to maintain the web’s position. Innovations in control algorithms and digital signal processing (DSP) techniques have greatly enhanced their effectiveness:

- Advanced Control Algorithms: Modern web guide controllers use sophisticated algorithms to process sensor data and control actuators. These algorithms can predict and correct deviations more accurately than traditional methods.

- Machine Learning and Artificial Intelligence: The integration of machine learning and AI into control systems has revolutionized web guiding. These technologies enable predictive algorithms to analyze historical data, anticipate potential deviations, and make proactive adjustments. Machine learning models can also adapt to changes in the manufacturing process, continually optimizing the system’s performance.

4. Real-time Monitoring and Feedback

Continuous real-time monitoring and feedback are crucial for maintaining precision in web guide systems:

- High-Speed Data Acquisition: Modern systems are equipped with high-speed data acquisition capabilities that continuously track the web’s position. This enables rapid detection and correction of deviations, minimizing errors and improving accuracy.

- Instant Feedback Mechanisms: Real-time feedback systems provide immediate data to the control system, allowing for quick adjustments. This real-time capability is essential for maintaining high precision in fast-paced manufacturing environments.

Implications of Enhanced Precision in Web Guide Systems

The advancements in precision and accuracy of web guide systems have profound implications for the industrial manufacturing sector. These improvements are not just technical achievements; they translate into significant benefits across various aspects of manufacturing processes.

1. Improved Product Quality

Enhanced accuracy in web guide systems ensures that the web material remains properly aligned throughout the production process. This consistent alignment leads to several quality improvements:

- Uniformity: Precise web guiding results in uniform products, reducing variations that can lead to defects.

- Defect Reduction: Accurate alignment minimizes issues such as wrinkles, folds, and edge misalignments, which are common causes of defects in continuous materials.

- Better Print Quality: In printing applications, precise web guiding ensures that patterns and text are consistently aligned, leading to higher print quality and fewer misprints.

2. Reduced Material Waste

Material waste is a significant concern in manufacturing, both from a cost and environmental perspective. Enhanced precision in web guide systems contributes to waste reduction in several ways:

- Fewer Rejected Products: Improved accuracy leads to fewer defects, reducing the number of products that must be discarded or reworked.

- Efficient Material Usage: Accurate alignment allows for optimal use of material width, minimizing excess trim and off-cuts.

- Lower Scrap Rates: Enhanced precision reduces the likelihood of web breaks and other issues that result in wasted material.

3. Increased Production Efficiency

Precision in web guide systems directly impacts production efficiency, enhancing the overall throughput and effectiveness of manufacturing processes:

- Higher Speeds: Accurate web guiding enables higher production speeds without compromising quality, increasing overall throughput.

- Reduced Downtime: Fewer alignment issues mean less downtime for adjustments and repairs, keeping production lines running smoothly.

- Consistent Performance: Reliable web guiding systems maintain consistent performance over long production runs, ensuring that quality and efficiency are sustained.

4. Cost Savings

The cumulative effect of improved product quality, reduced material waste, and increased production efficiency translates into significant cost savings for manufacturers.

- Lower Production Costs: Efficient use of materials and reduced waste lower the overall cost of production.

- Reduced Labor Costs: Automated, precise web guiding systems reduce the need for manual adjustments and oversight, lowering labor costs.

- Lower Maintenance Costs: Enhanced accuracy leads to fewer mechanical issues and breakdowns, reducing maintenance expenses.

5. Enhanced Flexibility and Adaptability

Advanced web guiding systems with enhanced accuracy offer greater flexibility and adaptability, allowing manufacturers to respond to changing market demands and production requirements.

- Versatility: Accurate web guiding systems can handle a wide range of materials and thicknesses, enabling manufacturers to diversify their product offerings.

- Quick Changeovers: Enhanced precision facilitates faster and more accurate changeovers between different products and materials, improving responsiveness to market demands.

- Scalability: Manufacturers can scale their operations more effectively, knowing that their web guide systems can maintain accuracy across varying production volumes.

6. Competitive Advantage

Manufacturers that adopt advanced web guide systems with enhanced precision gain a significant competitive edge

- Market Differentiation: High-quality, consistent products help manufacturers differentiate themselves in competitive markets.

- Customer Satisfaction: Reliable product quality and reduced defects lead to higher customer satisfaction and loyalty.

- Innovation: Manufacturers can pursue innovative product designs and manufacturing techniques that require precise material handling, further setting them apart from competitors.

7. Environmental Sustainability

Enhanced accuracy in web edge guide systems contributes to more sustainable manufacturing practices.

- Resource Efficiency: Reduced material waste and efficient use of resources support sustainability goals and reduce the environmental footprint.

- Energy Savings: Increased production efficiency often translates into lower energy consumption, further supporting environmental sustainability.

Conclusion

The precision and accuracy improvements in web guide systems highlight the power of technological innovation in enhancing industrial manufacturing processes. With advancements in sensor technologies, actuation mechanisms, intelligent control algorithms, and real-time monitoring, modern web guide equipment offer unparalleled performance and reliability. As technology continues to evolve, we can expect even greater strides in the precision and accuracy of web guiding control systems, further revolutionizing the manufacturing landscape.