How Compact Design in Web Guide Systems Optimize Space and Performance

Table of Contents

The compact design of web guide systems addresses the growing demand for space-efficient and high-performance solutions in industries. This design philosophy emphasizes functionality within minimal spatial footprints, integrating advanced technologies to ensure precision and adaptability in diverse manufacturing environments.

Understanding Compact Design in Web Guide Systems

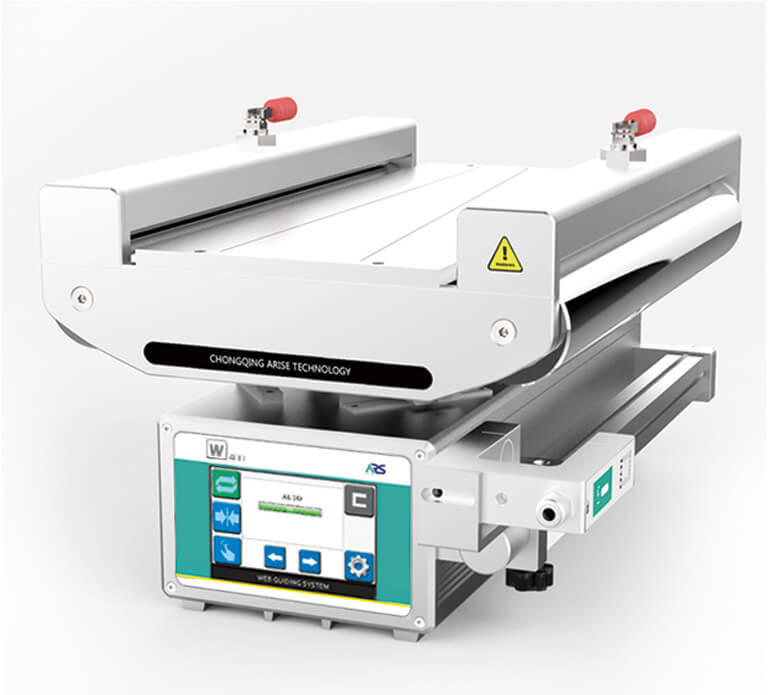

A compact design in web guide systems involves creating streamlined, space-saving devices that integrate essential components such as sensors, actuators, and controllers into a unified and minimalistic structure. This design philosophy addresses the challenges of modern manufacturing environments, where space is at a premium and production lines must adapt to diverse requirements.

Key Features of Compact Design in Web Guide Systems

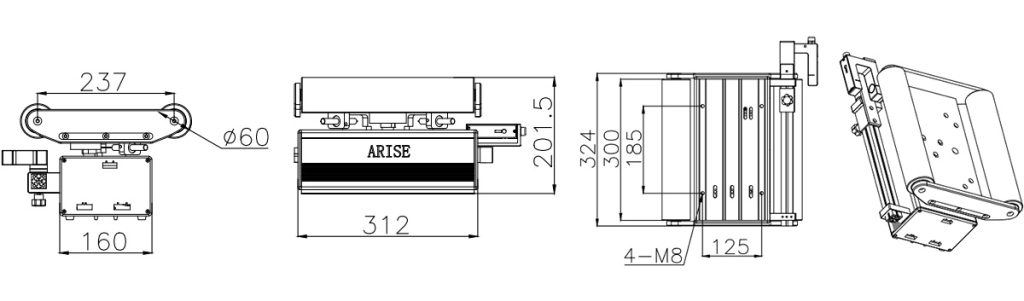

- Space-saving Structure: Compact web guide systems are engineered with a minimal footprint, making them ideal for installation in limited spaces without compromising functionality or performance.

- Integrated Components: Critical components such as sensors, actuators, and guide controllers are consolidated into a single, unified system, reducing external wiring and enhancing reliability.

- Lightweight Materials: Use of advanced lightweight yet durable materials, such as aluminum alloys or composites, ensures a reduced overall weight while maintaining structural integrity.

- Energy Efficiency: Compact designs often incorporate energy-efficient motors and electronics, minimizing power consumption while maintaining performance.

- Ease of Installation and Maintenance: The simplified design reduces installation time and makes maintenance straightforward, lowering overall downtime.

- Robust Construction: Despite their small size, these systems are designed to withstand industrial conditions, offering durability and consistent performance.

Key Components of a Compact Web Guide System

This chart summarizes the essential components of a compact web guide system, highlighting their functions and the advantages they bring to precise and efficient material handling.

| Component | Function | Advantages |

| Web Guide Sensors | Detects the position of the web material (e.g., edge, center). | Ensures precise alignment and minimizes material misalignment. |

| Web Guide Actuators | Moves the guiding mechanism to correct the web’s position based on sensor feedback. | Provides quick and accurate adjustments for high-speed applications. |

| Web Guide Controller | Processes sensor data and controls the actuator movements. | Enables seamless integration and precise control of the system. |

| Guide Mechanism | The physical component (e.g., rollers or frames) that moves or holds the web in place. | Maintains web tension and alignment with minimal wear. |

| We Guide Roller Frame | Provides structural support for all components in a compact design. | Ensures durability and stability while saving space. |

| Power Supply | Provides the necessary energy for sensors, controllers, and actuators. | Supports efficient operation with minimal power consumption. |

| Connectivity Interfaces | Enables communication with external systems (e.g., PLCs, HMIs, or wireless networks). | Allows integration into smart manufacturing environments for real-time monitoring and control. |

| Feedback Display | Displays system status, errors, and adjustments. | Simplifies monitoring and enhances user-friendliness. |

| Calibration Mechanism | Allows for initial setup and periodic recalibration of the system. | Ensures consistent performance and adaptability to different materials. |

Applications of Compact Web Guide Systems

This chart highlights the diverse applications and advantages of compact web guide systems across various industries, showcasing their adaptability and precision in enhancing production quality.

| Industry | Application | Benefits |

| Printing | Ensuring precise alignment of substrates for high-quality printing on paper, labels, and films. | Reduces print defects, enhances efficiency, and ensures vibrant and accurate outputs. |

| Packaging | Guiding plastic films, foils, and paper in high-speed packaging machines. | Prevents material misalignment, reduces waste, and ensures uniform sealing and cutting. |

| Textile Manufacturing | Maintaining fabric alignment during weaving, dyeing, or coating processes. | Improves fabric quality, reduces defects, and ensures consistency across production batches. |

| Flexible Electronics | Aligning delicate materials like thin conductive films in electronics manufacturing. | Protects sensitive materials, improves precision, and supports advanced production technologies. |

| Metal Processing | Handling metal foils and sheets in processes like slitting, coating, or laminating. | Ensures precise cuts, reduces material waste, and minimizes machine wear. |

| Labeling | Aligning labels during high-speed application processes. | Ensures accurate label placement, improves aesthetics, and reduces product rejection rates. |

| Battery Manufacturing | Aligning separator films and electrode sheets in battery production. | Increases efficiency, reduces material waste, and ensures uniform battery performance. |

| Food Processing | Guiding packaging materials for food items in automated production lines. | Enhances package integrity, reduces contamination risks, and ensures compliance with standards. |

Innovations in Compact Design of Web Guide Systems

These advancements enhance the precision, efficiency, and adaptability of compact web guide systems, catering to the demands of modern industries with limited operational spaces and a focus on high performance.

1. Miniaturized Sensors and Actuators

- Infrared and Ultrasonic Sensors: Miniaturized sensors provide accurate web edge detection in compact spaces, ensuring high precision without bulky hardware.

- Compact Actuators: Sleek, high-torque actuators reduce system size while maintaining robust control over web alignment.

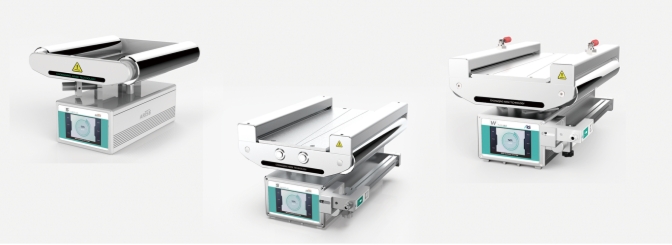

2. Integrated and Modular Designs

- All-in-One Units: Integration of sensors, actuators, and controllers into a unified system reduces space requirements and simplifies installation.

- Modular Systems: Compact modules can be customized or replaced individually, providing flexibility for upgrades or specific applications.

3. Advanced Materials

- Lightweight Composites: Materials like carbon fiber and aluminum alloys reduce system weight while maintaining strength and durability.

- High-Strength Plastics: Advanced plastics contribute to compact designs without sacrificing robustness.

4. Smart Technology Integration

- AI and Machine Learning: Algorithms enable predictive adjustments for precise web alignment, adapting to material variations in real time.

- Wireless Connectivity: Compact systems now include wireless options for seamless integration into Industry 4.0 environments.

5. Energy-Efficient Motors

- Micro-Motors: Advanced, energy-efficient micro-motors reduce size and power consumption.

- Optimized Drive Systems: Compact drive systems ensure smooth operation with minimal energy usage.

6. Improved Manufacturing Techniques

- 3D Printing: Additive manufacturing allows for the creation of highly intricate, compact designs that would be difficult with traditional methods.

- Precision Machining: Enhanced machining processes result in smaller, more precise components.

7. User-Friendly Interfaces

- Compact Control Panels: Simplified and integrated control panels make operation intuitive without requiring additional space.

- Touchscreen Displays: Compact web guiding systems now incorporate small, high-resolution touchscreens for user interaction and diagnostics.

8. Enhanced Durability in Small Packages

- Dust and Moisture Resistance: Innovations ensure that compact systems remain resilient in challenging industrial environments.

- Vibration Dampening: Compact web guiding control systems now include features to mitigate vibration impacts, ensuring consistent performance.

Overall, the compact design in web guide systems represents a significant advancement in web handling technology. Through combining advanced technology with space-saving designs, these systems meet the dual demands of precision and operational efficiency, ensuring high performance in a variety of applications. As industries continue to prioritize space and efficiency, compact web guide systems will play a pivotal role in modern manufacturing.