How Advanced Imaging Technologies are Revolutionizing Web Inspection Systems

Advanced imaging technologies have emerged as indispensable tools within web inspection systems, revolutionizing quality control processes across a spectrum of industries. From detecting defects to optimizing production processes, these systems play a pivotal role in enhancing efficiency and reducing waste. In this article, we delve into the significance of advanced imaging technologies within web inspection systems and their transformative impact on various sectors.

The Evolution of Web Inspection Systems

Web inspection systems have evolved significantly over the years, driven by advancements in imaging technology and automation. Traditionally, these systems relied on manual inspection methods, which were time-consuming, labor-intensive, and prone to human error. However, with the advent of advanced imaging technologies, such as high-resolution cameras, sensors, and artificial intelligence (AI), web inspection systems have become highly sophisticated and efficient.

Key Components of Advanced Imaging Technologies in Web Inspection Systems

1. High-Resolution Cameras

High-resolution cameras are at the core of advanced imaging systems in web inspection systems. These cameras capture detailed images of the entire web surface with exceptional clarity and precision. They are equipped with high pixel counts and sophisticated optics to ensure accurate representation of the inspected material.

2. Line Scan Cameras

Line scan cameras are specialized cameras designed to capture images of moving webs or materials. Unlike traditional cameras that capture entire images at once, line scan cameras capture images line by line, allowing for continuous inspection of the entire web width without distortion or blurring, even at high speeds.

3. Spectral Imaging Systems

Spectral imaging systems capture images at multiple wavelengths across the electromagnetic spectrum. This technology provides valuable spectral data that can be used to identify subtle color variations, detect defects, and analyze material properties that may not be visible to the naked eye or conventional imaging systems.

4. UV and Infrared Imaging

UV and infrared imaging technologies are used to detect defects and anomalies that may not be visible under normal lighting conditions. UV imaging can reveal fluorescent substances or coatings, while infrared imaging can detect temperature variations and structural abnormalities in materials.

5. Machine Vision and AI Algorithms

Machine vision systems use algorithms and artificial intelligence (AI) to analyze captured images and automatically detect, classify, and quantify defects. These algorithms are trained on large datasets and can identify defects based on predefined criteria, allowing for rapid and accurate defect detection without human intervention.

6. Illumination Systems

Illumination systems provide the necessary lighting to enhance contrast and visibility in captured images. Different types of illumination, such as diffuse lighting, backlighting, and strobe lighting, may be used depending on the specific inspection requirements and characteristics of the inspected material.

7. Optical Filters

Optical filters are used to selectively transmit or block specific wavelengths of light, allowing for targeted imaging and defect detection. Filters can be used to enhance contrast, remove background noise, and isolate features of interest in the captured images.

8. Image Processing Software

Image processing software is used to analyze and manipulate captured images, extract relevant features, and perform defect detection and classification. These software tools often include advanced image processing algorithms, statistical analysis tools, and visualization capabilities to aid in defect analysis and decision-making.

Applications Across Industries of Advanced Imaging Technologies in Web Inspection Systems

1. Printing and Packaging Industry

- Defect Detection: Web inspection systems are used to detect defects such as misprints, color variations, streaks, and registration errors in printed materials.

- Color Consistency: These inspection systems ensure consistent color reproduction and quality across printed packaging materials, maintaining brand integrity.

- Barcode Verification: They verify the accuracy and readability of barcodes, expiration dates, and batch codes on packaging, ensuring traceability and compliance with regulatory standards.

2. Flexible Packaging and Converting

- Material Inspection: Web inspection systems detect defects in flexible packaging materials, such as films, foils, and laminates, including imperfections like wrinkles, bubbles, and delaminations.

- Coating Quality: They monitor coating applications to ensure uniformity and adherence to specifications, preventing defects such as streaks, uneven coatings, and missed areas.

3. Textile Manufacturing

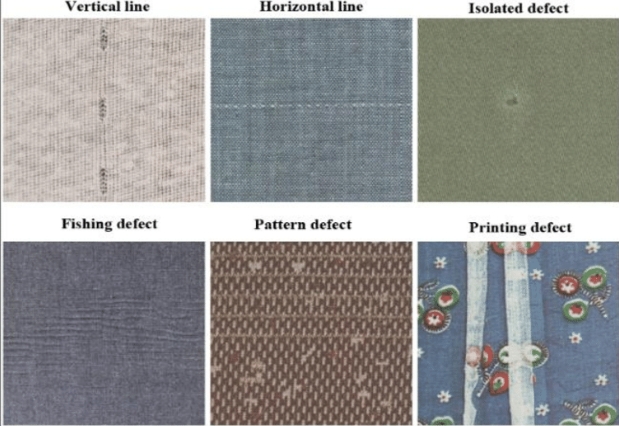

- Fabric Inspection: These systems inspect textiles for defects such as holes, stains, tears, and irregularities, ensuring the quality and consistency of finished textile products.

- Print Quality: In textile printing applications, web inspection systems ensure accurate print registration, color consistency, and defect-free printing on fabrics.

4. Nonwoven Industry

- Nonwoven Material Inspection: Web inspection systems detect defects and anomalies in nonwoven materials, including tears, holes, and irregularities, ensuring the integrity and performance of nonwoven products.

- Fiber Orientation: They monitor the orientation and distribution of fibers in nonwoven materials to ensure uniformity and quality in the final product.

5. Paper and Pulp Manufacturing

- Paper Quality Control: Web inspection systems monitor paper quality during the manufacturing process, detecting defects such as tears, spots, and coating irregularities, ensuring the production of high-quality paper products.

- Coating Inspection: They inspect coated papers for defects such as uneven coatings, streaks, and missed areas, ensuring uniformity and consistency in coating applications.

6. Food and Beverage Packaging

- Food Safety Assurance: Web inspection systems ensure the safety and integrity of food packaging materials by detecting contaminants, defects, and foreign particles that may pose a risk to food safety.

- Label Verification: They verify the accuracy and legibility of labels, nutritional information, and allergen warnings on food packaging, ensuring compliance with regulatory requirements and consumer safety standards.

7. Medical Device Manufacturing

- Quality Assurance: Web inspection systems inspect medical device packaging for defects, ensuring the integrity and sterility of medical products and devices.

- Barcoding and Serialization: They verify the accuracy and readability of barcodes, serial numbers, and product identifiers on medical device packaging, ensuring traceability and compliance with regulatory standards.

Benefits of Advanced Imaging Technologies in Web Inspection Systems

This chart highlights the various benefits that advanced imaging technologies bring to web inspection systems.

| Benefits | Description |

| Enhanced Defect Detection | Identification of even the smallest defects such as misprints, color variations, streaks, and registration errors. |

| Improved Product Quality | Consistent product quality and prevention of substandard products from reaching the market, enhancing brand reputation and customer satisfaction. |

| Increased Efficiency | Automation streamlines production workflows, reduces manual inspection, and minimizes downtime, optimizing production throughput. |

| Reduced Waste and Rework | Early defect detection minimizes waste, reduces the need for costly rework or scrap, and optimizes material usage. |

| Compliance Assurance | Ensures compliance with regulatory standards, including food safety regulations, labeling guidelines, and product specifications. |

| Data-Driven Decision Making | Provides valuable insights into production processes, enabling informed decisions, optimization of production parameters, and continuous improvement. |

| Enhanced Customer Satisfaction | Consistent product quality builds trust with customers, enhances satisfaction, and maintains a positive brand image. |

| Continuous Improvement | Facilitates a culture of continuous improvement by providing feedback on production processes and identifying areas for optimization. |

Conclusion

Advanced imaging technologies have transformed web inspection systems, revolutionizing quality assurance across various industries. With their unparalleled capabilities in defect detection, process optimization, and cost reduction, these systems have become indispensable assets across a diverse range of industries. As technology continues to advance, web inspection systems will play an increasingly critical role in maintaining high standards of quality and efficiency in manufacturing and production.