Evolving Web Guiding Systems: Industry Trends and Future Innovations

Web guiding systems are critical in many industries, ensuring perfect alignment and control of materials during manufacturing operations. Technology developments have resulted in substantial innovations in online guiding systems, improving their accuracy, efficiency, and adaptability. In this article, we will discuss the latest industry trends and future innovations in web guiding control systems that are shaping the manufacturing landscape.

Industry Trends of Web Guiding Systems

Vision-based Web Guiding Systems

The incorporation of vision-based technology is one of the noteworthy breakthroughs in web guide systems. Traditional systems depended on mechanical sensors and guides to maintain alignment, whereas vision-based systems use cameras and image processing algorithms to analyze the position of the web in real time. This enables faster and more precise adjustments, minimizing waste and increasing total production efficiency. Furthermore, vision-based systems can discover flaws or irregularities in the web, allowing for fast corrective action.

Machine Learning and Artificial Intelligence

The combination of machine learning (ML) and artificial intelligence (AI) has transformed web guiding control systems. ML algorithms can identify prospective misalignments and automatically make corrections based on prior data and patterns, reducing the need for human intervention. AI-powered systems can adapt to varied materials and manufacturing environments, learning and optimizing the guiding process as they go. These technologies provide greater precision and consistency, resulting in superior product quality and less downtime.

Sensor Integration and Feedback Control

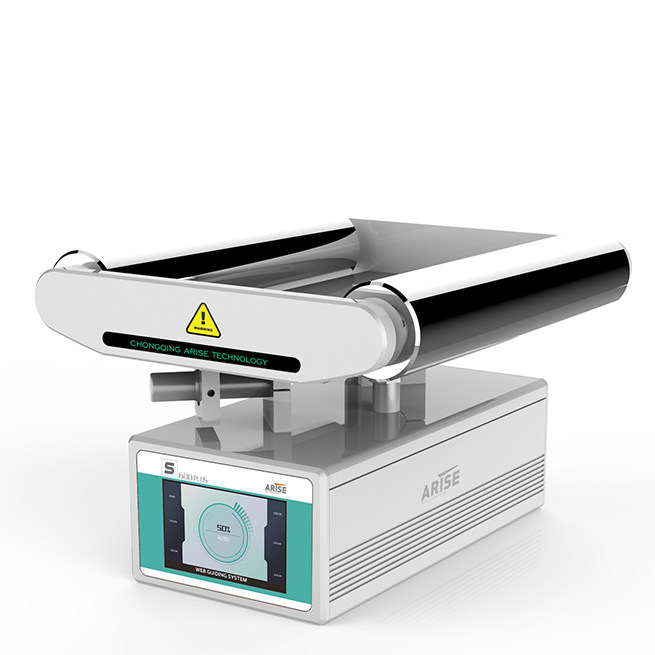

With the integration of modern sensors and feedback control mechanisms, web guiding machine have gotten more sophisticated. Capacitive, ultrasonic, and laser sensors are employed to correctly guide the web through the production process. The sensors’ real-time feedback enables for quick modifications and assures continual alignment. Moreover, closed-loop control systems can maintain precise tension control, compensating for speed variations and minimizing web-related issues such as wrinkles or breaks.

Non-Contact Web Guiding

NNon-contact web guiding systems have gained popularity in areas where material delicacy or contamination risks are a major issue. These technologies guide the web without making physical contact by using air, electrostatic forces, or electromagnetic fields. Non-contact guiding reduces the possibility of damage or contamination, which is especially important in delicate industries like as food processing, medicines, and electronics manufacture. Non-contact solutions are projected to become more popular as the industry prioritizes product quality and cleanliness.

Integration with Industry 4.0 and Industrial IoT

Web guiding equipment is becoming an important component of the larger Industry 4.0 ecosystem. These systems can collect and analyze massive volumes of data by integrating with Industrial Internet of Things (IIoT) platforms, enabling predictive maintenance and optimizing manufacturing operations. Web alignment systems can communicate in real time with other machines and systems, allowing for seamless coordination and automated modifications across the production line. This integration boosts overall efficiency, decreases downtime, and allows for proactive decision-making.

Future Innovations of Web Guiding Systems

Even more promising innovations await web guiding system in the future.

Advanced Material Compatibility

Web guiding systems will continue to evolve to support a wider range of materials, such as flexible substrates, thin films, and complicated composites. This expansion will allow other businesses, especially developing sectors such as flexible electronics and renewable energy, to benefit from an accurate web guide.

Enhanced Sensing Technologies

Sensor technology will evolve further, providing greater precision, faster response times, and increased material compatibility. Multi-dimensional measures can be included into advanced web guide sensors, enabling for more thorough web analysis and control.

Augmented Reality (AR) Interfaces

AR interfaces can give real-time guidance and visual overlays for operators, making web guiding adjustments more simple and efficient. These interfaces can display pertinent information such as web position, tension, and proposed modifications, thereby increasing operator productivity and decreasing human error.

Collaborative Robots

The combination of web guide control systems and collaborative robots opens up new avenues for automation. Collaborative robots can aid human operators in web directing duties and improve production productivity. They can also improve safety by doing repetitive or hazardous activities.

Summary

Evolving of web guiding systems is altering industrial processes in a variety of industries. The combination of vision-based systems, machine learning and artificial intelligence algorithms, enhanced sensors, and non-contact technologies has resulted in increased accuracy, efficiency, and adaptability. We should expect increasing automation, improved material compatibility, and advanced sensing capabilities as web guide machine expand and combine with Industry 4.0 technology. These innovations will result in increased production, decreased waste, and enhanced product quality, establishing web guiding systems as an important component in the modern manufacturing scene.