Customization and Adaptability of Web Video Inspection Systems in Modern Manufacturing

In today’s fast-paced world of manufacturing and production, product quality is critical. The integration of web video inspection systems has been a major changer, allowing for real-time monitoring and analysis of manufacturing processes. What distinguishes these systems is their versatility, which caters to the specific requirements of diverse sectors and production processes. This article explores the intricacies of customization and adaptability, highlighting how web video inspection systems are tailored to meet the unique needs of diverse industries and ever-evolving production processes.

Understanding Web Video Inspection Systems

Web video inspection systems use advanced camera technology, artificial intelligence, and machine learning algorithms to monitor and inspect manufacturing processes. These systems are designed to record high-resolution photos and videos, enabling for extensive analysis and real-time detection of faults or anomalies.

| Aspect | Description |

| Components | Camera, lights, cables, reel, monitor, and control unit. |

| Camera Types | Pan-and-tilt cameras, push cameras, robotic cameras. |

| Lighting Options | LED lights integrated into the camera or external lighting. |

| Applications | Inspection of pipes, sewers, ducts, tanks, wells, etc. |

| Flexibility | Suited for various diameters, lengths, and types of inspection environments. |

| Operational Modes | Manual operation, remote control, automated scanning. |

| Recording Capabilities | Image and video capture for documentation and analysis. |

| Integration with Other Systems | Compatibility with GIS, data management, and reporting systems. |

| Remote Monitoring | Capability for real-time viewing from a remote location. |

| Data Transmission | Wired or wireless transmission of video and inspection data. |

| Hazards Mitigation | Reduces the need for human entry into hazardous environments. |

| Maintenance Requirements | Regular maintenance to ensure camera and lighting functionality. |

Customization and Adaptability to Different Industries of Web Video Inpsection Systems

| Industry | Adaptability of Web Video Inspection Systems |

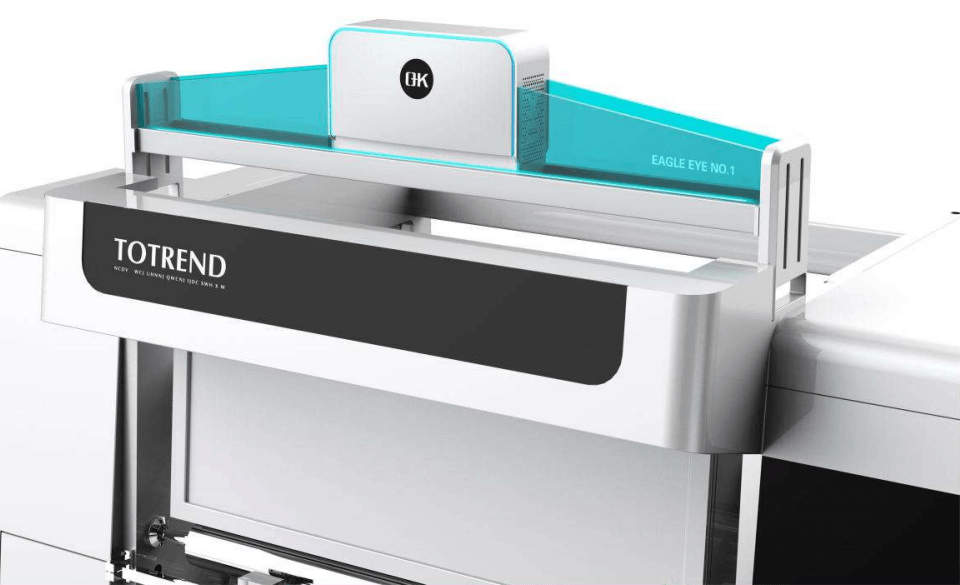

| Printing | Printing quality control and inspection of manufacturing processes. |

| Automotive | Inspection of automotive components, assemblies, and systems. |

| Aerospace | Examination of aircraft components, engines, and structures. |

| Oil and Gas | Inspection of pipelines, wellbores, and oilfield equipment. |

| Power Generation | Assessment of power plant infrastructure and equipment. |

| Construction | Inspection of construction sites, structures, and materials. |

| Electronics | Quality control for electronic components and circuitry. |

| Pharmaceuticals | Inspection of pharmaceutical manufacturing processes and products. |

| Food and Beverage | Quality assurance in food processing and packaging. |

| Telecommunications | Inspection of communication infrastructure and network components. |

| Chemicals | Monitoring of chemical manufacturing processes and equipment. |

| Infrastructure Maintenance | Inspection of bridges, tunnels, and other critical infrastructure. |

| Environmental Monitoring | Examination of environmental structures and pollution control systems. |

| Mining | Inspection of mining operations, equipment, and safety measures. |

| Research and Development | Exploration and inspection in research and development environments. |

| Security and Surveillance | Monitoring and surveillance for security applications. |

| Wastewater Management | Inspection of wastewater treatment systems and pipelines. |

How Customization and Adaptability of Web Video Inpsection Systems Contributes to the Optimization of Manufacturing Processes

1. Tailoring Solutions to Industry Specifics

One of the distinguishing advantages of web video inspection systems is their flexibility to be adapted to the specific challenges of various sectors. Quality control standards vary by industry, from car manufacturing to pharmaceuticals. Web video inspection systems can be tailored to meet these industry-specific problems, ensuring that the inspection process is consistent with the requirements and demands of the unique production environment.

2. Flexibility in Configuration and Parameters

The adaptability of web inspection systems is demonstrated by their versatility. Manufacturers can tailor these systems to the specifics of their production processes. Inspection criteria, tolerance levels, and fault detection algorithms are all parameters that can be customized. This flexibility allows producers to fine-tune the system in response to changing needs and product specifications.

3. User-Friendly Interfaces for Seamless Customization

Web inspection vision systems have user-friendly interfaces because they understand the value of user interaction. This ensures that all operators, regardless of technical background, may quickly explore and adjust the system. The user-friendly interfaces enable quick changes to settings, inspection criteria, and other factors, allowing for real-time adaption to production dynamics.

4. Adaptive Integration of AI and Machine Learning

The use of artificial intelligence (AI) and machine learning (ML) increases the adaptability of web video inspection systems. These technologies enable the system to continuously learn from and adapt to new data sources. As patterns form and production processes mature, the system gets increasingly adept at detecting flaws and anomalies. The adaptive nature of AI and ML allows for a proactive approach to quality management.

5. Real-Time Feedback and Corrective Actions

The real-time capabilities of web video inspection systems contribute to their adaptability by providing immediate feedback. When anomalies are detected, the system can trigger alerts, notifying operators to take corrective actions promptly. This real-time adaptability minimizes the risk of producing substandard products and contributes to maintaining the integrity of the manufacturing process.

6. Scalability for Changing Production Needs

The adaptability of web video inspection machine extends to scalability. Whether a production facility undergoes expansion, contraction, or technological upgrades, these systems can scale accordingly. This scalability ensures that the investment in inspection technology remains relevant and valuable over the long term.

7. Beyond Visual Inspection

While visual inspection is a primary focus, modern web inspection systems go beyond mere visuals. Some systems integrate additional sensors and technologies to improve their inspection capabilities, such as measuring dimensions, analyzing structural integrity, and evaluating thermal qualities. This adaptability enables manufacturers to tailor inspections to the individual characteristics of their products.

Conclusion

Customization and adaptability define the modern landscape of web video inspection systems. These solutions not only meet the distinct needs of many industries, but also provide producers with the flexibility to adapt to changing manufacturing processes. As automation and Industry 4.0 advances, customizable and adaptable nature of web inspection system ensures they remain at the forefront of quality control, contributing to the efficiency and perfection of varied manufacturing sectors.