Case Study: Successful Implementation of Web Guiding Systems in ABC Manufacturing – Enhancing Precision and Efficiency

Staying competitive in the ever-changing manufacturing landscape necessitates embracing technological advancements that improve precision, efficiency, and overall production quality. This case study delves into the success story of ABC Manufacturing, a forward-thinking industry player that improved its production processes dramatically by implementing web guiding systems. We look at the challenges that ABC Manufacturing faced, the solutions that were chosen, and the tangible benefits that were realized.

Why Choosing the Implementation of Web Guiding Systems in ABC Manufacturing Facility

Background:

ABC Manufacturing specializes in the manufacture of flexible packaging materials for a variety of industries, including food and beverage, pharmaceuticals, and consumer goods. To meet the increasing demands for quality and efficiency, the company identified a critical need to improve the precision of its manufacturing processes, particularly web alignment.

Challenges Faced:

1. Inconsistent Web Alignment

ABC Manufacturing was dealing with issues related to inconsistent web alignment, which was causing product defects and increased waste. Manual adjustments took time and frequently resulted in production delays.

2. Downtime and Productivity Loss

The manual nature of the alignment process resulted in frequent downtime, which harmed overall productivity. To minimize disruptions, the company recognized the need for a more automated and efficient solution.

3. Quality Control Concerns

Variations in web alignment were causing quality control concerns in an industry where precision is critical. ABC Manufacturing aimed for greater consistency in order to meet stringent quality standards.

Selected Solution: Web Guiding Systems Implementation

ABC Manufacturing conducted a thorough evaluation of potential solutions to their web alignment issues. After careful consideration, the decision was made to implement state-of-the-art web guiding systems tailored to the unique requirements of their production line.

How to Implement Web Guiding Systems in ABC Manufacturing Facility Successfully

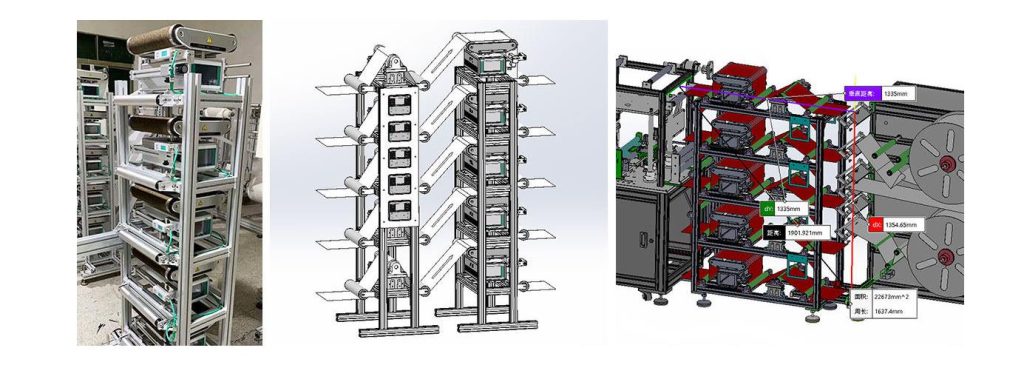

Key Components of the Implemented Web Guiding System

1. High-Resolution Optical Sensors

ABC Manufacturing chose web-guiding systems with high-resolution optical sensors. These sensors provided precise real-time feedback on the material’s position, ensuring precise alignment.

2. Advanced Actuators

The systems chosen featured advanced web guide actuators that combined servomotors and pneumatic cylinders. This dynamic combination enabled quick and precise adjustments to ensure optimal web alignment.

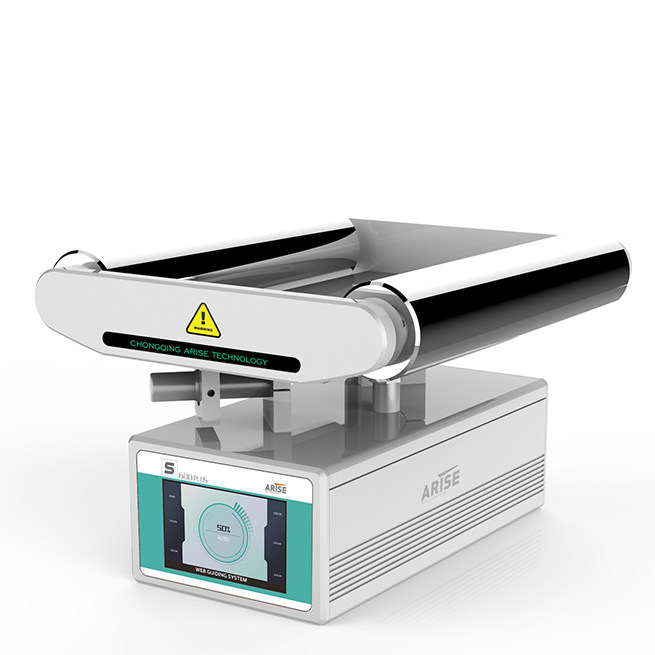

3. User-Friendly Controller with Programmability

The system was integrated with a programmable, user-friendly web guide controller. This enabled operators to set parameters, fine-tune adjustments, and adapt the system to various materials and production needs.

Steps for Successful Implementation

1. Assessment of Requirements

Conduct a thorough assessment of the manufacturing process to identify specific web guiding requirements. Think about things like material type, width, and processing speed.

2. Selection of Appropriate System

Choose a web guide system machine that aligns with the identified requirements. Consider the type of sensor technology, controller capabilities, and compatibility with existing machinery.

3. Integration with Existing Equipment

Ensure seamless integration with the existing production line. Collaborate with the system provider to adapt the web guiding solution to the unique characteristics of the facility.

4. Operator Training

Train operators on the proper use and maintenance of the web guiding system. Familiarize them with the user interface and troubleshooting procedures to minimize downtime.

5. Performance Monitoring

Implement a monitoring system to track the performance of the web guiding system. Regularly review data to identify areas for optimization and preventive maintenance.

6. Continuous Improvement

Embrace a culture of continuous improvement. Regularly evaluate the effectiveness of the web guiding system and explore opportunities for enhancements or upgrades to keep pace with evolving technology.

What are the Benefits of Implementing Web Guiding Systems in ABC Manufacturing Facility Successfully

1. Precision and Consistency

ABC Manufacturing’s implementation of web guiding systems resulted in a significant improvement in web alignment precision. The consistency of the production line improved, resulting in fewer variations in the final product.

2. Dramatic Reduction in Waste

WABC Manufacturing experienced a significant reduction in material waste thanks to the automated adjustments provided by the web guiding system. This not only saved money but also aligned with the company’s commitment to sustainability.

3. Enhanced Productivity

Downtime from manual adjustments was virtually eliminated. The web guiding system increased overall productivity significantly, allowing ABC Manufacturing to meet production targets more efficiently.

4. Quality Assurance and Customer Satisfaction

The increased precision in web alignment directly influenced product quality. ABC Manufacturing could now confidently meet and exceed its clients’ stringent quality standards, improving overall customer satisfaction.

5. Adaptability to Changing Requirements

ABC Manufacturing was able to quickly adapt to changing production requirements thanks to the web guiding system’s programmability. This adaptability proved invaluable when dealing with a wide range of materials and product specifications.

Conclusion

The successful implementation of web guiding systems demonstrates the transformative power of advanced manufacturing technologies. By addressing the issues of inconsistent web alignment, downtime, and quality control concerns, the ABC manufacturing not only optimized its production processes, but also established itself as a precision manufacturing leader. This case study highlights the significance of strategic technology adoption in remaining competitive and meeting the changing demands of the modern manufacturing landscape.