Interesting Facts I Bet You Never Knew About Web Guiding System

In coil processing, due to the deviation of the coil itself or the machine, once the edge of the coil is not aligned, it will cause errors in subsequent processes, resulting in material waste or machine adjustment. In order to reduce the occurrence of such situations, the web guiding system can provide a solution for the edge position control of the coil.

Why Choose Web Guiding System For Edge Position Control

What is the web guiding system?

Web control refers to the technical operation that the coils must always be kept neat and consistent during the spraying, printing, punching, laminating, slitting, or other coil winding processes. When processing coils, it is necessary to perform edge guiding timely on the offset coils. This process is called web guiding. The equipment of the whole process constitutes a system. The web guiding system includes a controller, a web guide sensor, an electric drive, and a web guide mechanism.

Working principle of the web guiding system for edge control

The web guiding system is a closed-loop controller, which includes the controller, sensor, and web guide mechanism, as the basic complements of the system. First, the sensor detects the edge or of the coil, and the system automatically reads the offset of the actual position and the setting of the coil. Convert the offset into an electrical signal and send it to the controller. After the signal is amplified and calibrated by the controller, it is output to the driver. The linear driver drives the deviation correction mechanism according to the magnitude of the signal, to restore the coil to the set position. The drive signal of the current driver is only proportional to the deviation of the coil, which makes the web guiding system possible to provide precise control for various coils.

When the rolling speed of the material is relatively low, the speed of the motor should be low speed, otherwise, it will easily lead to over-correction. When the rolling speed is relatively high, then the speed of the motor should also be a high-speed correction. Adjust the winding speed of the correction motor through the frequency adjustment. The automatic web guiding can also be operated manually. It has the functions of automatic detection, automatic tracking, automatic correction, etc, which can track and correct the edges of paper, non-woven fabrics, film, aluminum foil, strip steel and other materials to ensure the roll winding and slitting neatly.

Four types of web guiding

Edge Guiding

Web edge guiding refers to guidance on a single edge of the web material. This is the most common type. The edge of the operator side or driver side can be guided to the desired position according to the sensor position.

Center Guiding

Center guiding is used when the edges of the web are not flat or the width of the web changes during the production process, instead of positioning the web-based on one edge, to guide the centerline of the web. The center position is determined by using two sensors, each sensor is located on each edge of the web.

Line Guiding

The web can be guided based on the position of the printing line. This line is a fixed reference for the printing position on the web. In most cases, camera-based solutions are used to guide the web according to the printing line.

Contrast Guiding

Similar to line guiding, the web can be guided based on contrasting features on the web. The contrast of the printing or the contrast produced by the coating process can be used as a reference for web guiding.

Web guiding system used for edge position control

The guide or control for the edge position of the web is the most widely used web guiding system. For various applications, edge position control or guide is sufficient, especially if the roll-to-roll machine is designed to always convert webs with constant width. Usually, the edge sensor is located in the downstream span of the roll paper guide (except for the rewind guide). Generally, the edges of the web are sensed in the free span rather than on a roller.

Advantages of the web edge guiding

1. It can inspect and control the coils of any material and color.

2. Precision ball screw with accurate positioning

3. The tracking speed can be adjusted arbitrarily without changing the size of the belt shaft.

4. The guide roller can be equipped with a hard-anodized layer, rubber layer, and cork skin.

5. The fast feedback for the voltage and electric current, which can automatically restore and protect the internal circuit system, with good stability, quick action response. The tracked objects will never drop the needle or wrinkle.

6. Humanized design, complete functions with fast and easy operation.

7. The web guiding system can be flexibly installed with integrated, separated and any angle installation.

The applications of the web guiding system for edge position control

The web guiding system covers a wide range of applications, and it is essential in industries such as packaging, non-woven fabrics, printing, labels, building materials, paper pulp, household paper, plastics, cables, metal processing, corrugated paper processing.

Functions of the web edge guiding system

1. Track the edge of the coil, correct the unevenness of the coil when winding.

2. Track the edge of the material to keep the coating material equidistant from the edge.

3. According to the different roll speeds of the materials, the speed of the guiding system can be adjusted to keep balance with the materials.

Function Of Analog Control in The Web Edge Guiding System

The analog control includes the following 4 aspects

1. Analog controller

The controller mainly includes three parts: simulation, simulation control rules and simulation elimination. The controller adopts a Cortex-A9 micro-controller.

2. Correction driver

The actuator adopts the SE-150 deviation correction actuator. as a brushless DC motor, it has superior performance with a maximum speed which can reach 40mm/s.

3. The materials of the web guiding controller

The controlled objects are the coil materials, and under the high-speed condition, it receives the action of the uncontrollable force and cannot maintain the straight-line movement so that the width centerline deviates from the reference centerline.

4. Web guide sensor

This device adopts the ultrasonic sensor AE-210, which can complete high-resolution ultrasonic sensing and frequency conversion, directly communicating with the micro-processing.

Whole control process:

1. Sample the photoelectric sensor through the single-chip microcomputer.

2. Simulate the adopted data after processing.

3. Analyzing the relative deviation of the controlled objects.

4. Querying the analog control rule table.

5. Selecting the corresponding control strategy.

6. Send it to the actuator to drive the motor for edge guiding.

Summary

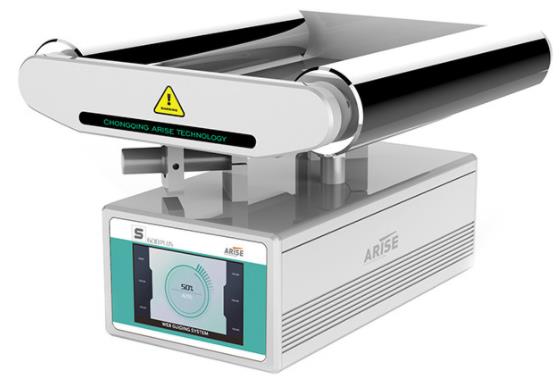

The web guiding system has a compact structure, good mechanical rigidity, low inertia, high precision, suitable for high-speed and high-precision edge position guiding in the middle of coil processing. Arise is one of the leading edge controller manufacturers in China and the product from Arise has a high-performance automatic system with continuous precise edge control for the coil materials.