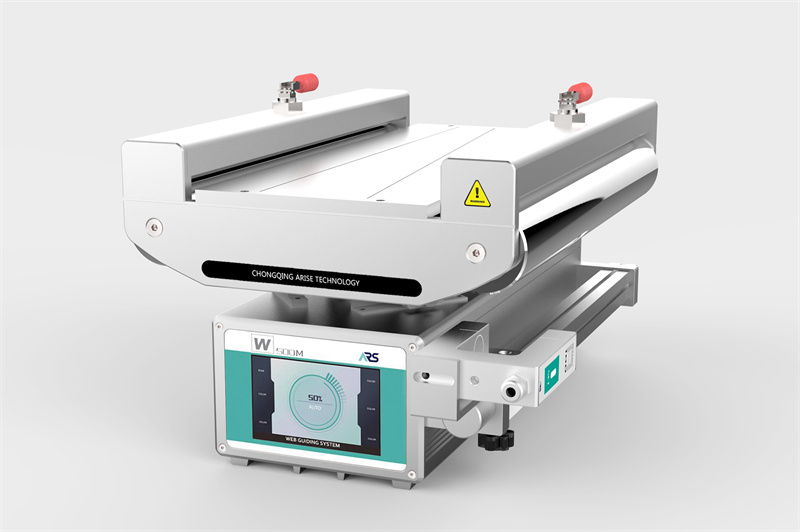

Affordable Web Guide Systems Suited for Small Enterprises

Table of Contents

Web guiding systems are essential for maintaining the alignment of various materials, such as paper, film, etc, as they move through production lines. Historically, web guide technologies have been complex and costly, accessible primarily to large industrial operations. However, with advancements in technology, affordable web guide technologies are now available to small enterprises, enabling them to improve production efficiency, reduce material waste, and enhance product quality. This article delves into affordable web guide systems suited for small enterprises, highlighting their benefits, types, and the latest innovations driving accessibility and cost-effectiveness.

Importance of Web Guide Systems for Small Enterprises

Web guide systems ensure that materials being processed on a production line are kept properly aligned throughout the manufacturing process. Misalignment or “web wander” can result in production defects, increased waste, and higher operational costs. For small enterprises with limited budgets, even slight material wastage can have a significant impact on profitability.

Implementing affordable web guide technologies allows small businesses to:

- Reduce Material Waste: By keeping materials properly aligned, web guide systems prevent costly errors, saving on raw materials.

- Enhance Product Quality: Proper alignment ensures that finished products meet quality standards, reducing the need for rework or rejection.

- Boost Operational Efficiency: Web guide systems streamline production processes, reducing downtime and minimizing the need for manual adjustments.

- Increase Profitability: With fewer defects and less waste, small enterprises can improve production efficiency and maximize profit margins.

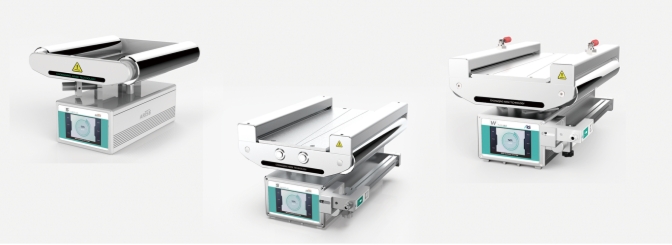

Types of Affordable Web Guide Systems

Several types of web guide systems are now available at affordable price points, making them accessible to small enterprises. These systems vary in complexity and functionality, allowing businesses to choose solutions that match their specific needs and budget.

| Web Guide System Type | Description | Key Benefits |

| Electromechanical Systems | Uses mechanical sensors and actuators to detect and correct web misalignment. | – Low cost – Easy to install -Reliable for basic applications |

| Pneumatic Systems | Utilizes air pressure to adjust the web position, suitable for lightweight materials. | – Affordable – Energy-efficient -Simple design with low maintenance |

| Ultrasonic Systems | Employs ultrasonic edge sensors to detect and align transparent or reflective materials. | – High precision -Suitable for delicate or transparent materials |

| Infrared Systems | Uses infrared web guide sensors to guide reflective materials, ensuring accurate alignment. | -Excellent for reflective materials – Automated adjustments |

| Optical Systems | Optical sensors detect web edges for real-time adjustment, useful for high-speed lines. | – High accuracy -Works well with a wide range of materials |

| Miniaturized Systems | Compact versions of traditional web guide systems, designed for easy integration in smaller setups. | – Cost-effective – Space-saving – Ideal for small enterprises |

| Plug-and-Play Systems | Pre-configured systems that require minimal setup and can be quickly integrated into production. | – Easy installation – Reduces downtime -User-friendly for small-scale production lines |

Key Factors to Consider for Choosing Affordable Web Guide Systems

Selecting the right web guiding system depends on the specific needs of your production line, material type, and budget.

1. Material Type

Consider the type of material being processed (e.g., paper, film, plastic, textiles). Different materials require different guiding technologies, such as optical, ultrasonic, or pneumatic systems. For example, transparent or reflective materials may need ultrasonic or infrared systems for proper alignment.

2. Production Speed

The speed of the production line plays a significant role in selecting a web guide system. High-speed operations may need more advanced, precise systems like optical or infrared guides, while slower lines can work with more basic, affordable systems like electromechanical or pneumatic guides.

3. Budget Constraints

Align your choice with your business’s financial capacity. Opt for systems that balance cost and functionality, ensuring the technology meets your operational needs without unnecessary expenditure. For smaller enterprises, plug-and-play or miniaturized systems often offer cost-effective solutions.

4. System Accuracy Requirements

Depending on the precision needed in the production process, select a web guiding control system with an appropriate level of accuracy. For high-precision applications, ultrasonic or optical systems may be necessary, while low-precision processes can rely on more affordable electromechanical systems.

5. Ease of Installation and Integration

For small enterprises with limited technical staff, ease of installation and integration is crucial. Plug-and-play systems offer quick setup and minimal downtime, while more complex systems may require professional installation, adding to the overall cost.

6. Maintenance and Durability

Consider the maintenance needs of the system. Affordable web guide systems that offer low maintenance costs and long-term reliability are ideal for small businesses with limited resources. Electromechanical and pneumatic systems generally have simpler maintenance compared to more complex sensor-based systems.

7. Energy Efficiency

Choose systems that are energy-efficient to reduce operational costs. Pneumatic and newer electric systems are designed to consume less power, making them ideal for small enterprises that need to minimize overhead.

8. Automation Level

Evaluate the level of automation required. If the production line demands frequent adjustments, investing in a system with automated web alignment could improve efficiency and reduce labor costs. Optical and ultrasonic systems offer higher automation but come at a higher price, while electromechanical systems are typically more manual.

9. Future Scalability

Consider whether the system can scale with your business as it grows. Opt for solutions that are modular and can be expanded or upgraded as production demands increase without requiring a complete system overhaul.

Key Innovations Driving Affordable Web Guide Systems

- Miniaturized Sensors and Components: Recent advances in sensor technology have led to the miniaturization of sensors and actuators, reducing the size and cost of web guide systems. These compact systems offer the same functionality as larger, more expensive models, making them more affordable for small enterprises.

- Plug-and-Play Systems: Pre-configured and user-friendly systems that require minimal setup and integration have become more prevalent. These plug-and-play solutions simplify installation, reducing the need for specialized technicians and minimizing downtime, which is especially beneficial for small businesses.

- Energy-Efficient Designs: New web guide systems are designed with energy-saving components, such as low-power motors and sensors, which reduce energy consumption and operational costs. Pneumatic systems and next-generation electric actuators are examples of energy-efficient solutions tailored for small enterprises looking to cut operating costs.

- Affordable Digital Controllers: The development of low-cost digital web guide controllers has allowed for better precision and automation without significantly increasing costs. These controllers enable more accurate web alignment and real-time monitoring, which is crucial for reducing waste and improving product quality in small-scale production.

- Advanced Sensor Technologies: Ultrasonic, infrared, and optical sensors are becoming more affordable due to advancements in manufacturing. These sensors provide high accuracy in detecting web edges, guiding transparent, reflective, or thin materials with minimal manual intervention, making them suitable for more complex production lines.

- Smart Algorithms for Web Positioning: The integration of smart algorithms and real-time data processing into web guide systems has enhanced performance by enabling automated adjustments based on real-time feedback. This reduces the need for constant manual adjustments, improving production efficiency and reducing waste.

- Integration with IoT and Automation Platforms: Modern web guide systems now offer integration with IoT and automated production systems, allowing for remote monitoring, predictive maintenance, and improved operational efficiency. These innovations make it possible for small enterprises to leverage sophisticated tools without heavy investment.

- Modular System Designs: Modular web guide systems allow small enterprises to purchase basic components and later add more features as their needs evolve. This approach provides scalability and flexibility without the need for costly upgrades or full system replacements.

- Cost-Effective Materials: Innovations in manufacturing processes and materials have led to the use of affordable, durable components that extend the lifespan of web guide system equipment while keeping costs low. This ensures that small enterprises can invest in robust systems without the high price tag typically associated with industrial-grade equipment.

- Wireless and Remote Control Features: Many modern web guide systems now come with wireless control and monitoring options, allowing operators to adjust settings and monitor performance remotely. This innovation reduces the need for manual intervention and cuts down on staffing costs while maintaining high precision.

To sum up, with a range of options for affordable web guide systems, such as electromechanical, pneumatic, and sensor-based systems, small enterprises can now choose technologies that fit their budget while addressing specific production challenges. As innovations continue to drive down costs and improve functionality, small businesses can leverage these web guide technologies to stay competitive in the modern manufacturing industries.