Advanced Tension Sensor Technologies in Tension Control Systems

Advanced sensor technologies have revolutionized tension control systems by providing enhanced accuracy, real-time feedback, and adaptability to various materials and processes. This article explores the latest advancements in tension sensor technologies used in tension control systems, highlighting their principles, benefits, and applications.

The Critical Role of Tension Sensors in Tension Control Systems

Tension control systems are designed to maintain a constant tension in materials as they are processed. This is essential to prevent defects such as stretching, breaking, or wrinkling, which can compromise product quality. Effective tension control involves continuously monitoring the tension and making real-time adjustments to keep it within the desired range.

Tension sensors are the cornerstone of tension control systems. They provide the necessary feedback by measuring the tension and other relevant parameters of the material being processed. This data is then used to adjust the control mechanisms, ensuring that the tension remains consistent throughout the production process.

Benefits of Sensor-Based Tension Control

This chart provides a concise overview of the key benefits of incorporating sensor-based tension control systems in manufacturing processes.

| Benefit | Description |

| High Precision | Sensors provide accurate and consistent tension measurements, ensuring high product quality. |

| Real-Time Monitoring | Continuous feedback allows for immediate adjustments, maintaining optimal tension throughout the process. |

| Reduced Material Waste | Precise tension control minimizes defects such as stretching, breaking, or wrinkling, reducing material wastage. |

| Improved Efficiency | Automated adjustments enhance production speed and reduce downtime caused by manual interventions. |

| Enhanced Product Quality | Consistent tension ensures uniformity and quality in the final product, meeting industry standards. |

| Versatility | Advanced sensors can adapt to various materials and production environments, offering flexibility in applications. |

| Lower Maintenance Costs | Non-contact sensors reduce wear and tear on equipment, leading to lower maintenance and replacement costs. |

| Scalability | Sensor-based systems can be scaled to fit different production sizes and complexities, from small operations to large-scale manufacturing. |

| Data Analytics | Sensors provide valuable data that can be analyzed for process optimization and predictive maintenance. |

| Safety Improvements | Automated systems reduce the need for manual intervention, enhancing worker safety in hazardous environments. |

Advancements in Tension Sensor Technologies used for Tension Control Systems

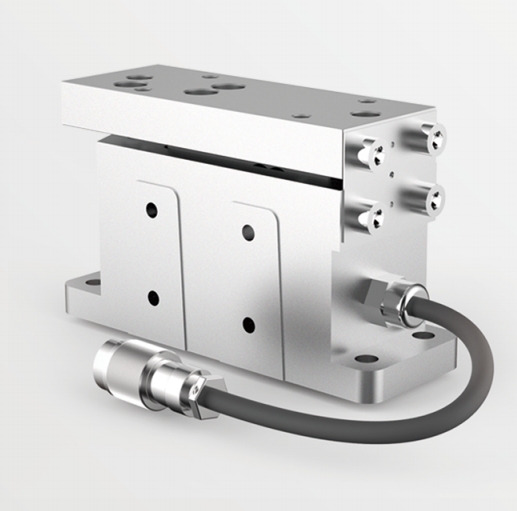

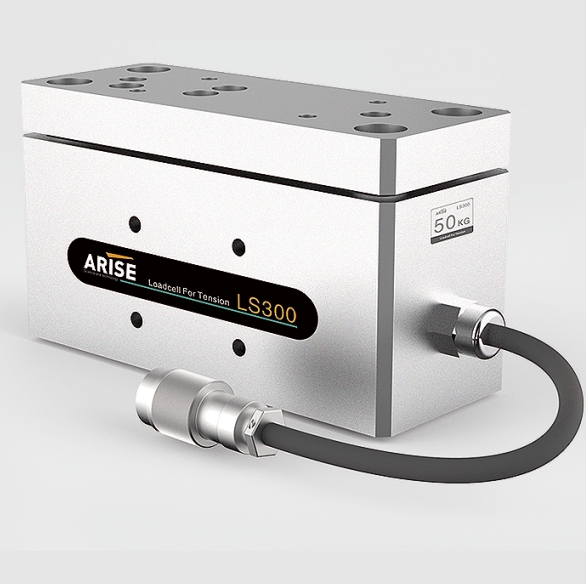

1. Load Cells

Principle

Load cells function by measuring the force exerted by the material as it travels through the system. These sensors convert mechanical force into an electrical signal proportional to the tension.

Advantages

- High Accuracy and Sensitivity: Load cells provide precise measurements essential for maintaining consistent tension.

- Real-Time Feedback: Instantaneous data allows for immediate adjustments, enhancing control and reducing errors.

- Versatility: Available in a wide range of capacities to suit different materials and applications.

Applications

- Web Tension Control: Used extensively in paper and film production to ensure uniform tension.

- Wire and Cable Manufacturing: Helps maintain the desired tension for quality control.

- Textile Processing: Ensures consistent tension in fabric production processes.

Limitations

- Installation Complexity: Requires careful setup and calibration.

- Mechanical Wear: Potential for wear and tear over time, necessitating maintenance.

2. Dancer Roll Systems

Principle

Dancer roll systems utilize a movable roller that adjusts its position based on the material’s tension. Sensors monitor the roller’s position, providing feedback to the control system to maintain consistent tension.

Advantages

- Simplicity and Effectiveness: Straightforward mechanism that effectively controls tension.

- Smooth Adjustments: Provides continuous tension adjustments.

- Flexibility: Suitable for various materials and operating speeds.

Applications

- Printing Presses: Maintains tension for high-quality prints.

- Converting Processes: Used in laminating, coating, and other converting operations.

- Laminating Operations: Ensures even tension during the laminating process.

Limitations

- Space Requirements: Requires adequate physical space for installation.

- Mechanical Wear: Components may wear out over time.

3. Optical and Laser Sensors

Principle

Optical and laser sensors use light beams to measure the position and movement of the material. Variations in the material’s position or speed are detected, enabling precise tension control.

Advantages

- Non-Contact Measurement: Reduces wear and maintenance.

- High Precision: Offers excellent accuracy and fast response times.

- Versatility: Suitable for measuring delicate or high-speed materials.

Applications

- Thin Film Production: Ensures precise tension in thin film materials.

- High-Speed Printing: Maintains tension in fast-paced printing processes.

- Textile Manufacturing: Used for inspection and quality control.

Limitations

- Environmental Sensitivity: Performance can be affected by dust, light, and other environmental factors.

- Higher Initial Cost: More expensive compared to traditional sensors.

4. Ultrasonic Sensors

Principle

Ultrasonic sensors emit high-frequency sound waves to measure the distance to the material. Changes in the distance indicate variations in tension, which are used to adjust the control systems.

Advantages

- Non-Contact and Non-Destructive: Avoids damage to materials.

- Insensitive to Material Properties: Effective regardless of material color and transparency.

- Durability: Performs well in harsh environments.

Applications

- Paper Production: Maintains tension in paper manufacturing.

- Textile Processing: Ensures consistent tension in fabric production.

- Metal Strip Production: Controls tension in metal processing.

Limitations

- Range and Resolution: Limited measurement range and resolution compared to other sensors.

- Interference: Can be affected by external noise.

5. Capacitive Sensors

Principle

Capacitive sensors detect changes in capacitance between the sensor and the material. Variations in material thickness, position, or tension alter the capacitance, providing feedback for tension control.

Advantages

- High Sensitivity: Detects subtle changes in material properties.

- Non-Contact Measurement: Minimizes wear and maintenance.

- Effectiveness with Thin Materials: Suitable for measuring thin and lightweight materials.

Applications

- Thin Film and Plastic Extrusion: Maintains tension during extrusion processes.

- Coating Processes: Ensures even tension in coating applications.

- Semiconductor Manufacturing: Used for quality control in semiconductor production.

Limitations

- Environmental Sensitivity: Performance can be influenced by humidity and temperature changes.

- Calibration Needs: Requires precise calibration and setup.

Conclusion

Advanced tension sensor technologies are integral to modern tension control systems, providing precise and reliable measurement capabilities essential for maintaining product quality and optimizing production processes. Load cells and dancer roll systems offer robust solutions for various materials and speeds, while optical, laser, ultrasonic, and capacitive sensors provide non-contact alternatives with high accuracy and fast response times. Selecting the appropriate sensor technology depends on specific application requirements, environmental conditions, and material characteristics, ensuring optimal performance and control.