Advanced Control Strategies in Web Guide Systems for Better Stability

Table of Contents

As the demand for higher quality products and more efficient processes grows, the need for advanced control strategies in web guide systems becomes increasingly important. Advanced control strategies are essential for enhancing the performance and stability of web guiding systems.

The Critical Role of Web Guide Systems

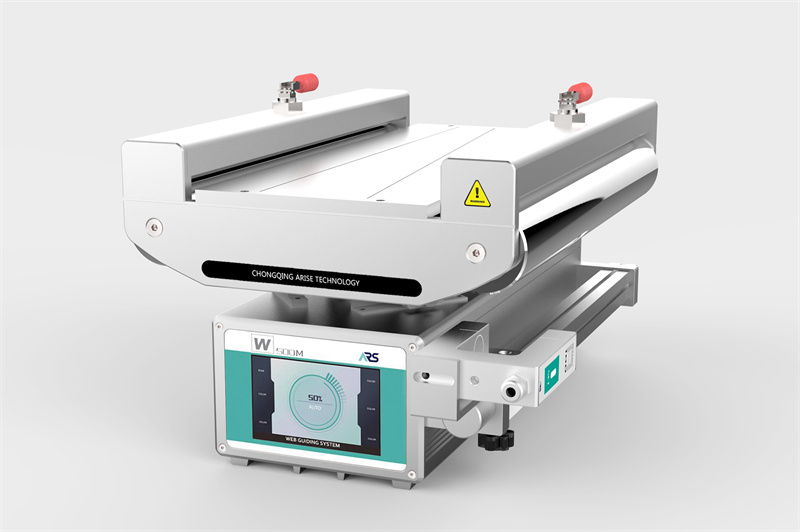

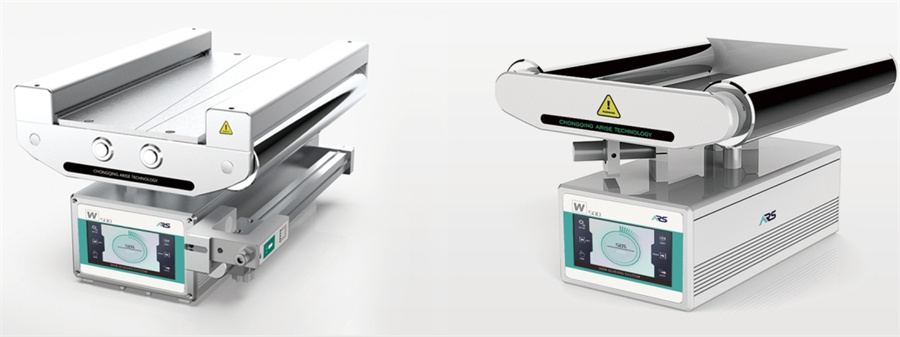

Web guiding systems are designed to correct lateral position errors of the web (material) as it moves through various stages of production. These systems are vital in preventing defects such as wrinkling, misalignment, and material wastage. Traditional web guide control systems rely on mechanical or simple feedback control mechanisms to maintain alignment. However, these systems can struggle with maintaining stability, especially in high-speed applications or when dealing with varying material properties.

Challenges Faced by Web Guide Systems

This chart highlights the main factors that can impact the performance and stability of web guide systems.

| Challenges | Description |

| Variable Material Properties | Differences in material characteristics (thickness, elasticity, tension) can cause inconsistencies in web movement, leading to misalignment. |

| High-Speed Processing | Operating at high speeds increases the risk of defects due to even minor misalignments, requiring more precise and responsive control mechanisms. |

| Environmental Conditions | Fluctuations in temperature, humidity, and other environmental factors can affect both the material and system components, impacting stability. |

| System Nonlinearities | Nonlinear behaviors within the system, such as friction or backlash, complicate the control process and can lead to instability. |

| Machine Wear and Tear | Over time, mechanical components may wear out, leading to reduced precision and control effectiveness. |

Advanced Control Strategies to Enhance the Stability of Web Guide Systems

To address these challenges, there is a clear need for more sophisticated control strategies that can adapt to dynamic conditions and maintain the desired web alignment.

1. Model Predictive Control (MPC)

Model Predictive Control (MPC) is an advanced control technique that uses a dynamic model of the web guide system to predict future behavior and optimize control actions. By continuously predicting the web’s position and adjusting the guide mechanisms accordingly, MPC helps maintain alignment even under changing conditions. Its ability to handle multi-variable processes and constraints makes it particularly suited for complex web guide systems.

2. Adaptive Control

Adaptive control systems adjust their parameters in real-time based on the current state of the web guide system. This type of control is beneficial when dealing with materials that have varying properties or when the system is subject to frequent changes. Adaptive control continuously updates its control strategy to maintain optimal performance, ensuring stable operation despite fluctuations in material characteristics or environmental conditions.

3. Fuzzy Logic Control

Fuzzy logic control is effective in managing the uncertainties and nonlinearities often present in web guide systems. Unlike traditional controllers that rely on precise mathematical models, fuzzy logic controllers use a set of heuristic rules to make control decisions. This approach allows for more flexible and robust control, making it easier to handle complex and unpredictable scenarios that might destabilize the web.

4. Neural Network-Based Control

Neural networks, which are capable of learning and adapting to complex patterns, can be used to develop control algorithms for web guide systems. These networks can be trained on historical data to predict the behavior of the web and determine the appropriate control actions. Once trained, a neural network-based controller can quickly adjust the system to maintain alignment, even in the face of rapid changes or unexpected disturbances.

5. Hybrid Control Systems

A hybrid control approach combines multiple control strategies to leverage their respective strengths. For example, a system might integrate MPC with fuzzy logic control, using MPC’s predictive capabilities alongside the robustness of fuzzy logic to handle a wide range of operating conditions. Hybrid systems offer a flexible and comprehensive solution, improving overall stability and performance in challenging environments.

Benefits of Implementing Advanced Control Strategies in Web Guide Systems

This chart highlights the key advantages of using advanced control strategies in web guide systems, emphasizing their impact on stability, quality, efficiency, and cost savings.

| Benefits | Description |

| Enhanced Stability | Advanced control strategies ensure consistent web alignment, reducing the risk of defects and interruptions. |

| Higher Product Quality | Improved control leads to fewer defects like wrinkles and misalignments, resulting in better overall product quality. |

| Reduced Material Waste | Precise control minimizes misalignment and errors, leading to less material waste and more cost-effective production. |

| Increased Production Speed | Advanced strategies enable the system to operate at higher speeds without sacrificing stability or quality, increasing throughput. |

| Adaptability to Changing Conditions | Strategies like adaptive control allow the system to adjust in real-time to variations in material properties or environmental factors, ensuring continuous optimal performance. |

| Lower Maintenance Costs | With better control and reduced wear and tear, the system experiences fewer breakdowns, leading to lower maintenance costs over time. |

In summary, advanced control strategies in web guide systems are crucial for achieving better stability and precision in various industrial processes, which lead to improved alignment accuracy, reduced material waste, and enhanced overall efficiency.