3 Useful Tips To Know The Working Of Web Guiding System

A web guiding system is a mechanism used in a variety of sectors, including printing, packaging, and textiles, to provide correct alignment and control of a moving web or continuous material throughout manufacturing processes.

Sensors And Detectors Used In The Web Guiding System

To precisely detect the location and alignment of the web material being processed, web guiding system relies on a variety of sensors and detectors. These sensors and detectors are critical in delivering feedback to the control system, which subsequently changes the guiding mechanism to keep the web in the appropriate position.

Ultrasonic sensors

Ultrasonic web guide sensor identify the position and distance of objects by using high-frequency sound vibrations. They can determine the position of the web edge by producing ultrasonic waves and measuring the time it takes for the waves to bounce back after striking the web substance. To enable precise and non-contact web edge detection, ultrasonic sensors are commonly employed in edge guiding system.

Vision sensors

Vision sensors take photos of web content and analyse its location and alignment using cameras and image processing algorithms. They can recognise web elements like edges, lines, and patterns and deliver real-time data to the control system for web directing modifications. Vision sensors are extremely adaptable and can be utilised in edge, center, and combination guiding systems.

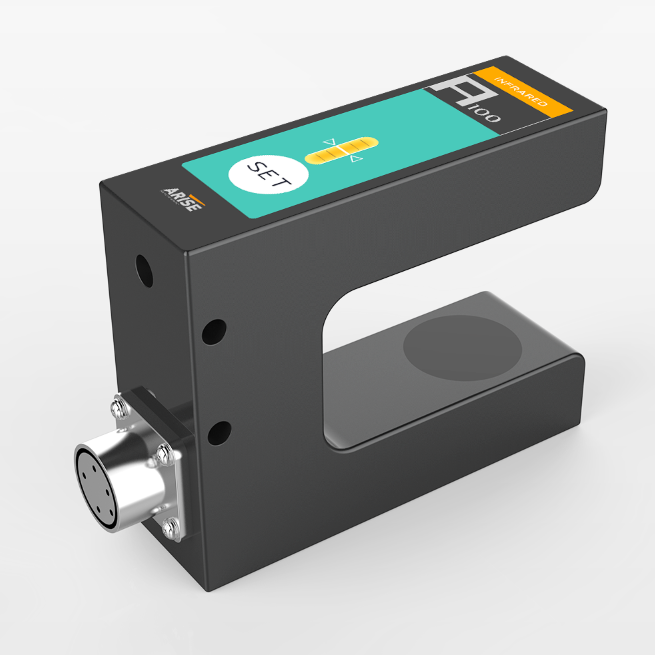

Infrared sensors

Infrared web guide sensor detect the presence and position of items by using infrared light. They can be used in web guiding systems to identify the web edge by producing infrared light and detecting the light’s reflection or transmission when it strikes web material. Infrared sensors are appropriate for applications where the web material is transparent or translucent, such as the plastic film and glass industries.

Capacitive sensors

Capacitive sensors operate on capacitance changes generated by the proximity of objects. They can determine the position of the web material by monitoring changes in capacitance when it comes into contact with the sensor. In centre guiding systems, capacitive sensors are typically employed to detect the position of the web material in reference to the centerline.

Laser sensors

Laser sensors employ laser beams to precisely measure distances and positions. They can be used in web guiding systems to precisely determine the position of the web edge by producing laser beams and monitoring the reflection or scattering of the beams from the web substance. Laser sensors are ideal for applications requiring great accuracy and resolution.

Load cells

Load cells are used to determine the tension or force of web material. They can be utilised to provide input to the control system for tension control and web guiding changes by being placed in the web route. Load cells are often employed in web tension control devices such as brakes and clutches to keep the web material tensioned and aligned.

Types Of Mechanisms In The Web Guiding System

Web guiding systems use a variety of techniques to keep the web information being processed in the appropriate position and alignment.

Edge Guiding

The most frequent sort of web guiding mechanism is edge guiding, in which the web edge guiding system adjusts the position of the web material based on the detection of one or both web edges. Edge guiding systems detect the position of the web edge(s) and then make changes to keep the web aligned along the desired route. To physically move the web material towards the desired position, edge guiding systems can include actuators such as steering rollers or guide rails.

Center Guiding

Center guiding, also known as line guiding or line following, is the process of sensing the position of the web material’s centerline and modifying the guiding mechanism accordingly. Sensors or detectors are commonly used in centre guiding systems to measure the location of the web material in relation to the centerline and subsequently make modifications to keep the web aligned along the centerline. To centre the web material, centre guiding systems can include actuators such as centre-driven rollers or adjustable guide bars.

Combination Guiding

As the name implies, combination guiding combines both edge guiding and centre guiding techniques. Multiple sensors or detectors are used in combination guiding systems to detect both the borders and the centerline of the web material. Based on the combination of edge and centerline information, the system calculates the best location for the web and changes the guiding mechanism accordingly. Combination guiding systems provide flexibility and accuracy in guiding web material, especially in applications requiring exact alignment.

The type of web guiding mechanism used is determined by several criteria, including the type of web material, the desired level of precision, the processing speed, and the application’s special needs. Edge guiding is frequently utilised for web materials that have clear edges, whereas centre guiding is appropriate for web materials that have well-defined centerlines. Combination guiding is frequently employed in applications that require both edge and centerline guidance for best performance.

Role Of Actuators In The Web Guiding System

Web guide actuators are key components of a web guiding system because they physically modify the position of the web material based on data from sensors or detectors. Actuators are devices that translate control system electrical, hydraulic, or pneumatic signals into mechanical motion in order to move or control the position of the web material.

Steering Rollers

In edge guiding systems, steering rollers, also known as dancer rollers or idler rollers, are typically utilised. They are positioned on adjustable arms or brackets that allow them to be moved horizontally or vertically to guide the web material. To keep the web material in the desired location, the steering rollers’ position is modified based on feedback from sensors or detectors.

Guide Rails

In edge guiding systems, guide rails are rigid structures or bars that are installed parallel to the web route. To guide the online material, they can be adjusted horizontally or vertically. To maintain the web material aligned along the desired path, the location of the guide rails is modified based on feedback from sensors or detectors.

Center-Driven Rollers

In centre guiding systems, centre-driven rollers are utilised to guide the web material down the centerline. They are powered by a motor and can be adjusted horizontally to centre the web material based on sensor or detector feedback. The speed of the centre-driven rollers is controlled by the control system in order to preserve the appropriate alignment of the web material.

Adjustable Guide Bars

In centre guiding systems, adjustable guide bars are utilised to guide the web material along the centerline. They are rigid bars that may be adjusted horizontally or vertically based on feedback from sensors or detectors to centre the web material. Adjustable guide bars are usually placed on both sides of the web material and can be changed separately to keep the appropriate alignment.

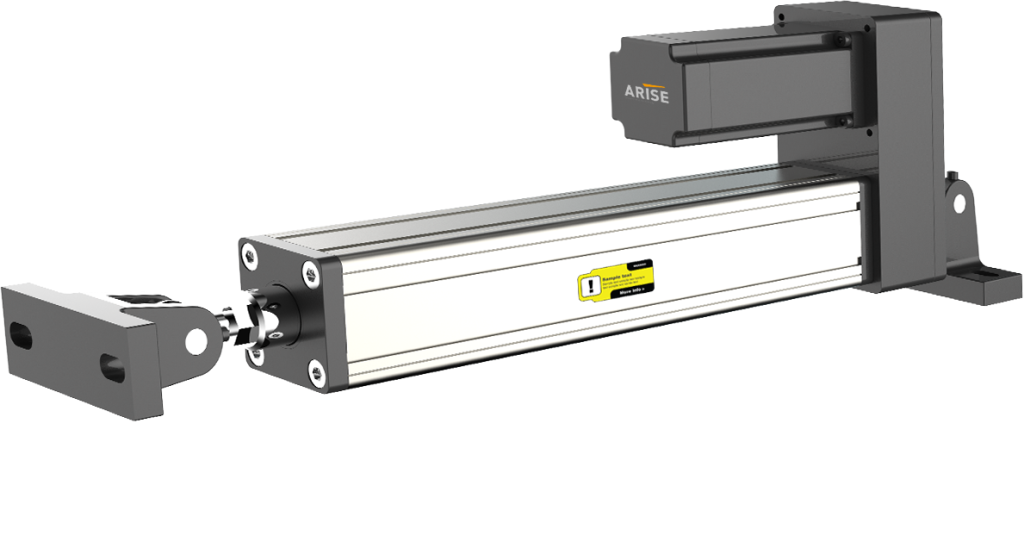

Pneumatic or Hydraulic Actuators

In some web guiding systems, pneumatic or hydraulic actuators are used to give accurate and forceful control of the web material. They generate mechanical motion and alter the position of the web material by using compressed air or hydraulic pressure. To obtain the appropriate guiding performance, pneumatic or hydraulic actuators can be utilised in conjunction with other types of actuators such as steering rollers or guide rails.

Summary

The web guiding system is used to keep the web precisely aligned and under control during manufacturing processes, ensuring high-quality output, reducing waste, and increasing overall productivity.