100% Inspection System for Print and Surface Quality

Why Choosing a 100% Inspection System for Printing and Surface Quality Control

Improve the final product quality while simultaneously reducing downtime and waste.

The O+K 100% print inspection system provides a comprehensive view of your printing process, allowing you to observe every detail. Whether it’s printing errors, stains, scratches, dents, or any other defects, you can detect them before your customers. When defects are detected, an immediate alert is issued to ensure the elimination of defective materials, thus optimizing your process and avoiding claims.

Benefits of 100% Inspection System

- Improved Quality: Ensures that every product meets the highest standards.

- Reduced Waste: Minimizes the production of defective products.

- Enhanced Customer Satisfaction: Delivers products that consistently meet expectations.

- Regulatory Compliance: Helps businesses meet industry regulations and standards.

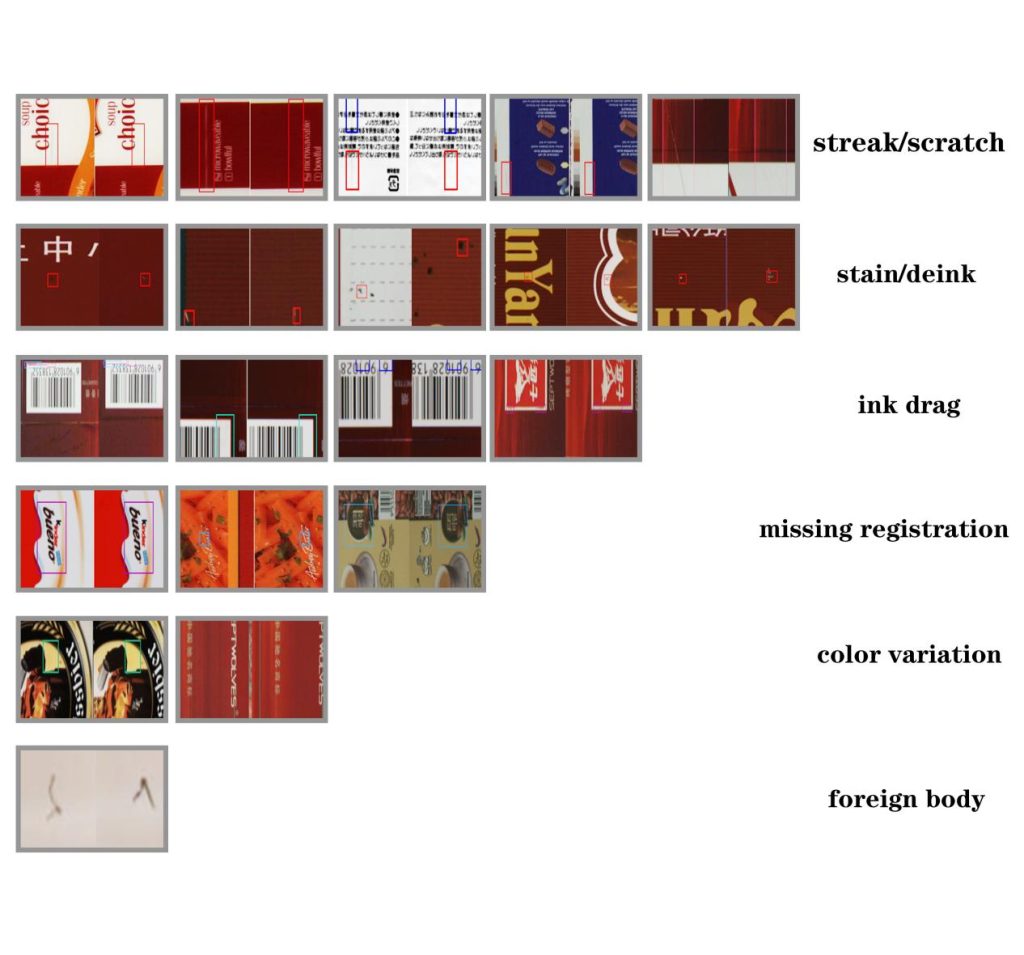

Typical Defects in Printed Materials

Eliminating Those Defects Means Reducing Complaints And Returns

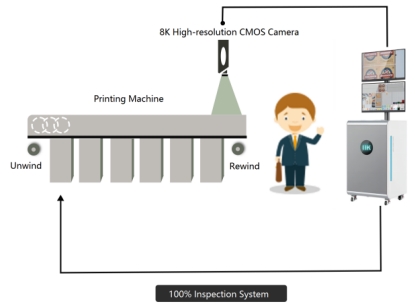

How Does a 100% Inspection System Work for Printing Quality Control

A 100% inspection system leverages advanced technology to examine every product in real-time, identifying defects that could compromise quality. Here’s a look of how a 100% inspection system works.

- The O+K 100% inspection system uses high-speed line scan cameras to scan the inspected objects and capture images of the product’s printed surface.

- Through image processing algorithms, the system compares the actual print images with pre-set standard images to detect potential defects such as color variation, smudges, ink drag, plate damage, and missing registration.

- Once defects exceeding the allowable range are detected, the system alerts the operator.

- This process allows the 100% inspection system to monitor print quality in real-time, ensuring that every printed product meets the set standards, thereby reducing waste and customer complaints.

- The printing inspection system also logs data on detected defects, providing valuable insights into production trends, quality issues, and operational efficiency. This data can be used for continuous improvement, helping manufacturers refine their processes and reduce waste.

- By implementing a 100% print inspection system, manufacturers ensure that every product meets stringent quality standards before it reaches customers.