100% Inspection vs. Sampling Inspection in the Printing Industry: Which Method to Choose

Quality control is a critical factor in the printing industry, ensuring that printed materials meet strict standards for accuracy, color consistency, and defect-free production. Two primary approaches to printing quality inspection are 100% inspection and sampling inspection. Each method has its advantages and limitations, and selecting the right approach depends on factors such as production volume, cost constraints, and quality requirements.

Table of Contents

Understanding 100% Inspection in Printing

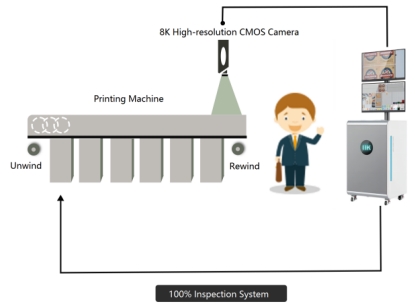

100% inspection, also known as full inspection, involves checking every single printed product for defects. Advanced automated systems, such as high-speed cameras and machine vision technology, are typically used in the 100% inspection system for printing to detect errors in color, alignment, registration, and overall quality.

Advantages

- High Accuracy: Ensures that every single product meets the required quality standards, reducing the risk of defects reaching customers.

- Enhanced Customer Satisfaction: Minimizes complaints and rejections by delivering defect-free prints.

- Ideal for High-Value Printing: Essential for critical applications such as pharmaceutical packaging, security printing, and high-end marketing materials.

- Automation-Driven Efficiency: Modern automated 100% inspection systems can quickly detect and reject defective prints without slowing down production.

Limitations

- Higher Cost: Requires investment in sophisticated inspection systems and additional resources.

- Potential Slower Production: Although automation reduces delays, some high-speed printing lines may experience bottlenecks.

- Risk of False Rejections: Extremely strict criteria may lead to unnecessary waste if minor, non-critical defects cause rejections.

Understanding Sampling Inspection in Printing

Sampling inspection involves examining a representative subset of the total production. Statistical methods are used to determine the sample size and frequency, ensuring that the results are reliable indicators of the overall quality. This approach is commonly used in large-scale printing operations where inspecting every unit is impractical.

Advantages

- Cost-Effective: Reduces inspection costs by examining only a subset of the total production.

- Faster Processing: Allows production to continue with minimal interruption.

- Suitable for Large-Volume Printing: Effective for industries where minor defects are tolerable, such as newspapers or general marketing materials.

Limitations

- Risk of Defects in Final Output: Since not all products are inspected, defective prints may reach the customer.

- Less Accuracy: A random sampling method may not always detect issues that occur sporadically.

- Not Suitable for Critical Printing Applications: In industries where perfection is mandatory, sampling may not provide adequate quality control.

Comparing 100% Inspection and Sampling Inspection in the Printing Industry

This comparison highlights that 100% inspection ensures maximum quality but at a higher cost, while sampling inspection is more efficient and cost-effective but comes with the risk of undetected defects.

| Aspect | 100% Inspection | Sampling Inspection |

| Definition | Examines every printed piece for defects | Checks a selected sample from the production batch |

| Accuracy | Detects all defects, ensuring complete quality control | Provides an estimated quality assessment based on sampled pieces |

| Defect Detection | Identifies all errors, preventing any defective prints from reaching customers | May miss defects that occur sporadically within the batch |

| Cost | Higher cost due to the need for automation and inspection systems | Lower cost as fewer prints are examined |

| Speed | Can slow production if not optimized properly | Faster since only a portion of the prints are inspected |

| Suitability | Best for high-precision printing (e.g., pharmaceutical packaging, security printing) | Ideal for high-volume printing where minor defects are acceptable (e.g., newspapers, brochures) |

| Technology Used | Requires advanced machine vision systems, AI, and high-speed cameras | Can be conducted manually or with basic statistical sampling tools |

| Risk of Defective Products | Almost zero, as all prints are inspected | Higher risk, as undetected defects may pass through |

| Flexibility | Less flexible due to continuous monitoring | More flexible and adaptable to different production volumes |

| Implementation Complexity | More complex due to high-tech requirements | Simpler and easier to integrate into existing workflows |

Key Factors to Consider for Choosing the Right Method Between 100% Inspection and Sampling Inspection

| Factor | 100% Inspection | Sampling Inspection |

| Quality Requirements | Best for applications demanding zero defects, such as pharmaceutical packaging, security printing, and premium branding materials | Suitable for products where minor defects are acceptable, like newspapers, brochures, and general commercial printing |

| Production Volume | More effective for low to medium-volume printing, where full inspection is feasible | Ideal for high-volume production, as inspecting every piece would slow down the process |

| Defect Tolerance | Used when no defects are permissible, ensuring flawless output | Works well when some defects are acceptable, based on statistical sampling |

| Cost Considerations | Requires high investment in automation, AI-driven vision systems, and high-resolution cameras | More cost-effective, as fewer resources are needed for inspection |

| Speed & Production Flow | Can potentially slow down production if not optimized properly | Faster, as only a portion of the prints are inspected, maintaining smooth workflow |

| Risk Management | Ensures zero defective products reach customers, minimizing recalls and reputational risks | Higher risk of defects slipping through, which may lead to customer complaints |

| Regulatory Compliance | Essential for strictly regulated industries like medical packaging and legal documents | Suitable for non-critical applications where occasional defects are acceptable |

| Flexibility & Adaptability | Less flexible due to the need for continuous monitoring | More adaptable, as inspection frequency can be adjusted based on production needs |

Summary

- Choose 100% Inspection when absolute quality and defect elimination are required for print inspection system, even at a higher cost.

- Choose Sampling Inspection when cost, efficiency, and production speed are the top priorities and minor defects are tolerable.

- Many printing companies also adopt a hybrid quality control strategy, using both 100% inspection and sampling inspection to optimize quality while maintaining efficiency. A common approach is to implement 100% inspection for critical sections of a print job, such as barcodes, logos, or legal text, while applying sampling inspection to less critical elements. Additionally, if defects are detected during sampling, printers can switch to full inspection to identify and correct production issues.

Final Thoughts

Both 100% inspection and sampling inspection are vital in quality control within the printing industry. While 100% inspection ensures absolute precision, it comes with higher costs and potential production slowdowns. Sampling inspection, on the other hand, offers a more cost-effective and faster alternative, but with a risk of undetected defects. The best approach depends on the nature of the printing job, industry requirements, and budget considerations. Through adopting automated printing inspection system and combining both methods where appropriate, printing companies can achieve optimal quality control while maintaining efficiency.